Flat Bar Automatic Roll Forming Production Line

PRODUCT DESCRIPTION

Uncoiler

The machine is in double-head mode. When one end of the uncoiler is producing online, the other end can be loaded with coil materials, saving time for winding. The frame is single-supported, and the material shaft of the uncoiler is manually driven to tighten the material roll, and the material roll is fixed on the material shaft of the uncoiler.The tightening structure is the result of connecting rods, and the working state is stable and reliable.In order to ensure the actual operation safety of the uncoiler, the uncoiler is equipped with a pneumatic brake device

Leveling machine

Structure:The machine adopts 7-roller leveling (3 rollers on the upper layer, 4 rollers on the lower layer, screw rod adjustment), 2 pairs of guide rollers, pneumatic clamping of the feeding rollers, frequency conversion speed regulation, and electrical switch control.

Straightening machine

Uses: Straighten the bending of the left and right directions of the sheet.

Structure: It is mainly composed of frame, straightening roller, adjustment mechanism and so on.

Parameters: Contains 6+9 sets of lateral straightening rollers and 2 sets of upper and lower pressure rollers

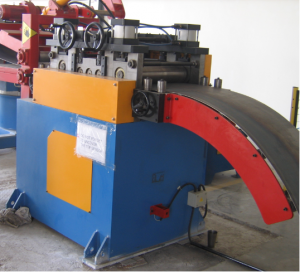

Deburr & Chamfering machine

Uses: Used to deburr and chamfer the edges of flat steel

Structure: mainly composed of frame, power system, cutting system, etc.

Chamfer:<2x45°

Motor power:4.5KW

Spindle speed:1500r

Loop Device

Uses: Used to buffer the speed mismatch between uncoiling leveling and gear punching machines, and to correct deviations. It is the whole line running smoothly and completely.

Structure: The material storage device consists of two parts: arc-shaped rollers and material-supporting devices. There are four groups of arc-shaped rollers, which are placed on both sides of the two storage bins respectively. It consists of an arc frame and a group of flexible rollers. , Hard chrome plating on the surface of the roller. A photoelectric switch is installed in the pit of the discharge bin to control the position of the coil entering the pit, so that the speed of each working part can be perfectly matched.

Electrical Control Units

The whole line adopts PLC and touch screen combined man-machine control mode. Specifications, quantity and parameters of parts can be set by touch screen, and multiple sets of operation instructions can be stored at one time. High degree of automation, it has alarm function in the case of abnormal production line, and the operation of the whole production line can be monitored through the control system. After power failure or abnormal shutdown, it can continue processing according to the working parameters set before.

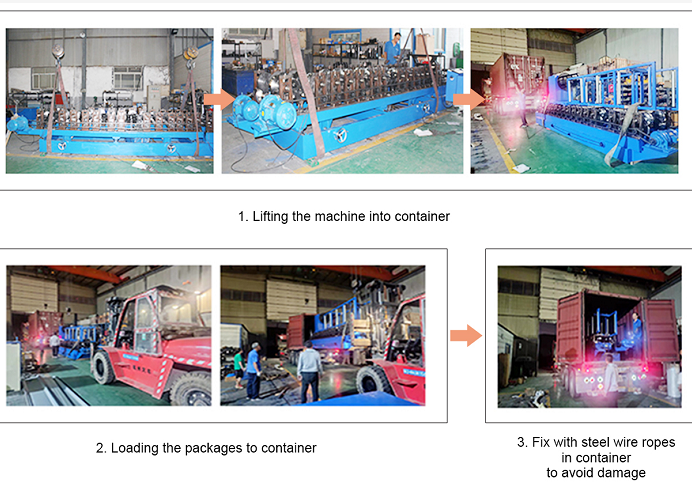

Package and shipment

The principle of moderation. According to the size, weight and transportation characteristics of the equipment, choose the appropriate size packaging box and packaging filler, and accurately calculate the amount of packaging materials in line with the standards of equipment export packaging, so as to reduce costs for customers.

The principle of convenience. The shape and size of the package are suitable for manual operation, convenient for storage, transportation and loading and unloading, and the loading and unloading efficiency is high.

Our Advantage

About us:

Our workshop started since the year of 2008, built by our founder member Mr. XU, who was worked as leader engineer for first-class roll forming department in SINOMRCH(China National Machinery Industry Corporation). After years of development, we have exported to many countries in the world such as Italy, Ecuador, America, India, Indonesia, Philipines, Brazil, Thailand, Vietnam, Russia, Malaysia, Peru, Korea etc. and gained high reputation from our customers and the agents. Up yo now, our workshop space around 5000 square meter, the annual capacity is 80 lines.

Technical strength:

1.We have an experienced expert with young active technical team, which can provide the professional with improved design solutions for our customers , assure that can satisfy various customer’s special requirement by cost-effective way.

2.Our engineer always keep on design advanced , humane and most economic resolution for our customers, considering customers long time machine life, low cost maintenance and easy operation, save the cost of labor, maintenance, training for users. At same time, much higher efficiency