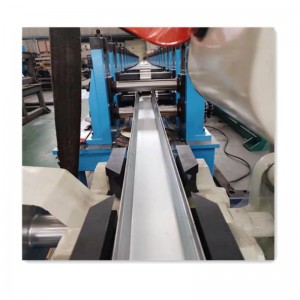

Hat Shape Profile Roll Forming Machine

GENERAL INTRODUCTION:

Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive.

| 1 | Machine structure | Individual archway stands structure |

| 2 | Total power | Motor power-18.5kw Hydraulic power-5.5kw |

| 3 | Roller stations | 18 dots stations |

| 4 | Productivity | 15-25m/min |

| 5 | Decoiler | 3T hydraulic decoiler |

| 6 | Leverling part | Upper is 3 rollers, down is 4 stations(total is 7 rollers) |

| 7 | Drive system | By independent gearbox |

| 8 | Diameter of shaft | ¢60mm solid shaft |

| 9 | Roller material | American D2 D3 |

| 10 | Pre punching& cutting system | Pre-cutting to change the material Material of the punching mold: Cr12 |

| 11 | Hydraulic cutting system | Cr12 with heat treatment 58-60° |

| 12 | Hydraulic power | 7.5KW |

Our hat profile roll forming machine is for making the hat channels, which widely applicable in metal/steel roof construction industries.

WORKING PRODUCTION:

Uncoiling → leveling → Looper (storage) → servo feeding → Multi-stations punching → forming station →hydraulic cutting → finished product discharging

MAIN PARAMETERS:

|

1 |

Automatic De-coiler | 1, Single head design 2, Loading weight: 3Tons 3, Hydraulic automatic expansion and tightening 4, Suitable width: <300mm 5, Coil ID: ¢500±20mm 6, Coil OD: ≤1200mm |

|

2 |

Servo Feeding Leveling |

|

|

3 |

Multi-functional Punching Machine | 1, 6 punching stations, 2, Servo motor power: 1.3KW 3, Servo motor brand: Japan Yaskawa 4, Suitable width: <300mm 5, Punching mold fast positioning, repeat positioning. |

|

4 |

Roll Forming Machine | 1, Driven system: Motor, reducer, spiral bevel gear drive 2, Main machine power: 15KW*2 Sets, 3, Motor brand: SIEMENS BADE servo motor 4, Module Components fast positioning, repeat positioning 5, Forming stations: 18 groups stations |

|

5 |

Hydraulic Cutting Machine | 1, Hydraulic single station, 2, Cutting force: 30Tons, 3, Cutting type: stop cutting 4, Module Components fast positioning, repeat positioning |

|

6 |

Computer Control Box | 1, Japan Mitsubishi motion controller PLC 2, Japan Yaskawa Servo System 3, With human machine interface touch screen 4, Schneider weak current control |

|

7 |

Hydraulic Station | 1,Hydraulic system power: 15KW 2,Hydraulic value: Huade, 3,With fan cooling system |

Write your message here and send it to us