High Frequency Tube Welding Mill Line

Product Description

High frequency straight seam welded pipe production line is mainly used to produce electric welded steel pipes with φ60~φ219mm and wall thickness of 2.0~6.0mm, and can also produce square and rectangular pipes and special-shaped pipes not exceeding the range of round pipes. API 5L tubes can be produced later by adding necessary equipment. The production line is designed and manufactured on the basis of digesting and absorbing similar equipment at home and abroad, combining with my country’s national conditions, boldly innovating, and listening to users’ opinions extensively. The equipment is economical, reliable and stable.

Basic Parameter

| Low carbon steel and low alloy steel | σB≤520mpa σS≤345mpa | |

| Steel Coil | inner diameter | φ650-φ710mm (to be determined) |

| Outer diameter | φ1100-φ2000mm | |

| Roll weight | ≤15 tons | |

| Strip width | 190-690mm | |

| Electrical installed capacity | about 1200KVA | |

| Compressed air capacity | 2m3/min 4-7Kg/cm2 | |

| Coolant capacity | 50 tons/hour | |

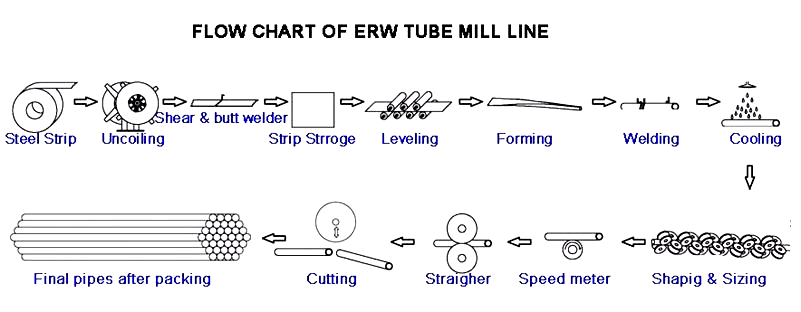

Production Process

Uncoiling → straight head, pinch leveling → shearing butt welding → looper → forming, high frequency welding, deburring, on-line zinc replenishment, cooling, sizing, rough straightening → flying saw sizing → inspection and collection → packing →Weighing→Marking→Storage

Welding Tube Mill line composition and main parameters of each machine

1.Feeding Trolley

|

Usage |

It is used to accept the strip coil, transport it to the decoiler, and lift the strip coil to the center of the coil head |

||

|

Structure |

It is composed of material rack, traveling mechanism, oil cylinder, guide rail, etc. |

||

|

Capacity |

≤15T |

Hold up |

Hydraulic |

|

Moving Mode |

Motor with cycloid reducer drive |

||

2.Uncoiler

|

Usage |

For hanging and supporting strip coils to provide raw material for production lines |

|||

|

Capacity |

≤15T |

Braking method |

Pneumatic brake, solenoid valve control |

|

|

Uncoiler |

Hydraulic expansion and contraction |

Single cone hydraulic expansion and contraction |

||

3.Straightening machine

|

Usage |

Used in conjunction with the uncoiler, the steel strip head is drawn from the uncoiler and sent to the pinch leveling machine for leveling |

||

|

Structure |

Press roller device, shovel head device, straight head device |

||

|

Width |

190-690mm |

Diameter |

φ1100-φ2000mm |

4.Pinch feeding and Leveling Machine

|

Usage |

Leveling the steel strip from the uncoiler and straightening machine at the head and tail and delivering the steel strip to the shearing butt welding machine |

||

|

Structure |

Composition of pinch roller, leveling roller and transmission device |

||

|

Width |

190-690mm |

Diameter |

φ1100-φ2000mm |

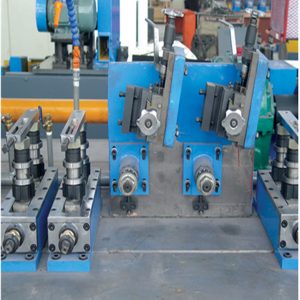

Tube Mill Line of Workpiece