Roll Forming Machine

-

Best Selling Cable Tray Roll Forming Machine

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc

-

High Quality Best Selling Truck Carriage Slide Plate Roll Forming Machine

Brief Introduction:

The carriage board production line equipment is an automatic equipment, used for making carriage top, bottom, and side plate” of truck carriage plate

Main Technical Parameters:

Material:hot rolled steel plate

Yield strength of raw materials: 235Mpa

Tensile strength of raw materials: 450Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strip width: ≤1000mm

Strip thickness: 1~1.2mm

Single roll weight: ≤7000 kg

-

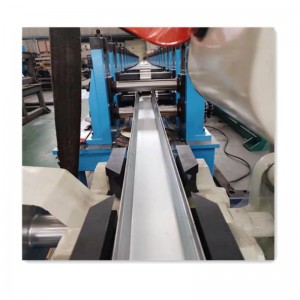

Changeable C U Z Purlin Roll Forming Machine

Production Description

Production Process

Decoiling→flattening→feeding→forming→length measuring→punching→hydraulic cutting→finished product

Components of the whole line

No.

Item

Unit

Qty

1.

Manual decoiler

set

1

2.

Leveling machine

set

1

3.

Main forming machine

set

1

4.

PLC Control box

set

1

5.

Hydraulic pump

set

1

6.

Punching and Cutting system

pcs

1

7.

Output table

pcs

1

Technical Parameters

Suitable material: galvanized steel or iron coil

Thickness: 1-3.5mm

Whole line size:18*1.5*1.6m

Forming speed:8-12m/min

-

Combined Two and Three Beam Roll Forming Machine

Raintech highway crash barrier roll forming machine have three types: Separated W beam roll forming machine, separated three waves crash barrier roll forming machine; combined two and three wave machine .

-

Two Wave Beam Highway Guardrail Roll Forming Machine

Raintech highway crash barrier roll forming machine have three types: Separated W beam roll forming machine, separated three waves crash barrier roll forming machine; combined two and three wave machine . We have many successful cases for export highway guardrail plate roll forming machine and C post roll forming .The punching machine is equipped with two complete sets of punching & cutting moulds .

-

Hat Shape Profile Roll Forming Machine

GENERAL INTRODUCTION: Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive. 1 Machine structure Individual archway stands structure 2 Total power Motor power-18.5kw Hydraulic power-5.5kw 3 Roller stations 18 dots stations 4 Productivity 15-25m/min 5 Decoiler 3T hydraulic decoiler 6 Lev... -

Double Deck Roofing Sheet Roll Forming Machine

Floor decking roll forming machine is manually used to produce steel floor decking and can produce high quality floor decking has advantages, such as no cutting deformation, high strength and a large working load. It can be directly mixed with the steel mesh and concrete with good adhesion. The main applications of decking sheets include thermal power plant, multilayer car shade parking, multi-story residential and commercial buildings such as shopping malls, bridges, platforms, walkways, mezzanines, silos, etc.

-

Fully Automatic Storage Rack Roll Forming Machine

This production line has the characteristics of high degree of automation, high efficiency, good stability, etc.; it has been used by many users in China and has won good customer reviews. The automatic production line of high-speed racking columns adopts fully automatic control, which greatly improves production efficiency and reduces labor intensity.

-

Best Selling Cable Tray Roll Forming Machine

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc

-

C U Z Purlin Roll Forming Machine

This line can produce C Z U and L shape metal profile on one machine, through only need to change some rollers.The uncoiler also contains 4 baffle plates to avoid the material from loosing during uncoiling.Main frame material:400# steel, thickness of Middle plate is 25mm. The main frame of machine is welded separately and the outside wall is connected by screw after being shot blasted on the surface. there are two purpose of being shot blasted: one, derusting. Two surface strengthening.

-

Cable Tray Roll Forming Production Line

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories.

This production line is mainly composed by following parts:

1. Uncoiler. Single support,four-bar tension structure, tension force comes from hydraulic cylinder, adjustment is fast and reliable.2. Leveler. It adopts 7 rollers for leveling, 2 pairs of guide rollers, feed rollers are pneumatically clamped, frequency conversion speed regulation, switch control.3. Looper ( Storage Material) Used to buffer the speed mismatch between the unwinding and leveling and the punching machine, and correct the deviation;4. Servo Feeder. The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick

5. Multi-stations Punching&Cutting Unit. It adopts liquid four-column press mode, which is economical, applicable and fast. The punching machine has a 6-station punching mode and contains 3 to 4 sets of die sets, which can continuously punch out multiple types of holes.6. Cantilever adjustable forming machine . The forming unit adopts the cantilever forming machine mode. Motor, reducer, spiral bevel gear drive.When producing products with different bottom widths and waist heights, you only need to set the parameters on the touch screen, which is convenient, fast and reliable. -

Hat Profile Roll Forming Machine

Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive.