Solar Strut Channel Roll Forming Machine

PRODUCT DESCRIPTION

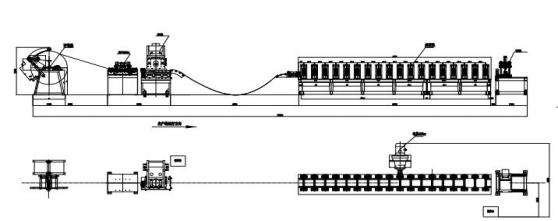

Solar strut channel roll forming machine production process

Uncoiler → leveler--- servo feeder→ punching station→ roll forming unit→ hydraulic shear→finished products

Uncoiler

Feature

The tensioning structure is connecting rod type, the working state is stable and reliable

The uncoiler is equipped with pneumatic brake.

In order to prevent the uncoiler from loosening during uncoiling, the uncoiling machine with

a pneumatic press arm to ensure the safety of the operator.

The uncoiler also contains four baffles to prevent the coil from deflecting or unwinding

Servo motor leveler and feeder

Structure: Frame+compression system+ servo drive system

Usage: According to the actual punching required step length into the sheet

material,can set multiple feeding parameters at one time, convenient and fast. Accurate feeding accuracy without cumulative tolerance.

Servo feeding machine contains 1 pair of feeding rollers, using spring pressing,

pneumatic loosing form.

Servo motor controls the feeding process

Punching Press

Purpose :

80T special hydraulic press is adopted, the punching position can be adjusted along the width of the material, with reasonable structure, long service life, easy adjustment and so on.The hydraulic system of this punching machine is specially developed for the multi-station punching machine.The hydraulic press adopts pump and accumulator control mode and special hydraulic control module, which has the characteristics of fast blanking speed and low noise,and is machine with cooler to dissipate heat, so as to meet the needs of continuous production.

Roll forming machine

Purpose: It is used to reach the desired interface shape through the roll bending process When the different specifications of the product replacement only need to replace part of the sleeves, can quickly replace the product.

Structure: The molding unit adopts independent stand (memorial archway mode).Motor, reducer drive, chain driven type

Hydraulic Shear unit

Purpose: It is to cut off the fixed length of the forming parts.

Feature: The cutting is done when the whole line keep running, without stop

fast and high efficiency .

Structure: The main components include shear frame, cutting die hydraulic system and so on.

Cutting blades: Total 3 sets (can complete cutting of 5 products)

Cutter material: Cr12MoV (HRC58~62 after quenching)

Hydraulic System

Hydraulic motor power:15kw

Hydraulic pressure: 22MPA

Purpose: To provide power for punching machine and cutting machine

Structure: pump and accumulator combined structure, fast blanking and shearing

speed improve the speed of production line.

Air cooler is used to dissipate heat and meet the requirements of high load

and high temperature.

The hydraulic system is a fast hydraulic system, suitable for high speed punch,

hole roll and shear roll forming production lines.

ADVANTAGE

Technical strength:

1.We have an experienced expert with young active technical team, which can provide the professional with improved design solutions for our customers , assure that can satisfy various customer’s special requirement by cost-effective way.

2.Our engineer always keep on design advanced , humane and most economic resolution for our customers, considering customers long time machine life, low cost maintenance and easy operation, save the cost of labor, maintenance, training for users. At same time, much higher efficiency

PACKAGE AND SHIPMENT

1. The principle of moderation. According to the size, weight and transportation characteristics of the equipment, choose the appropriate size packaging box and packaging filler, and accurately calculate the amount of packaging materials in line with the standards of equipment export packaging, so as to reduce costs for customers.

2. The principle of convenience. The shape and size of the package are suitable for manual operation, convenient for storage, transportation and loading and unloading, and the loading and unloading efficiency is high.

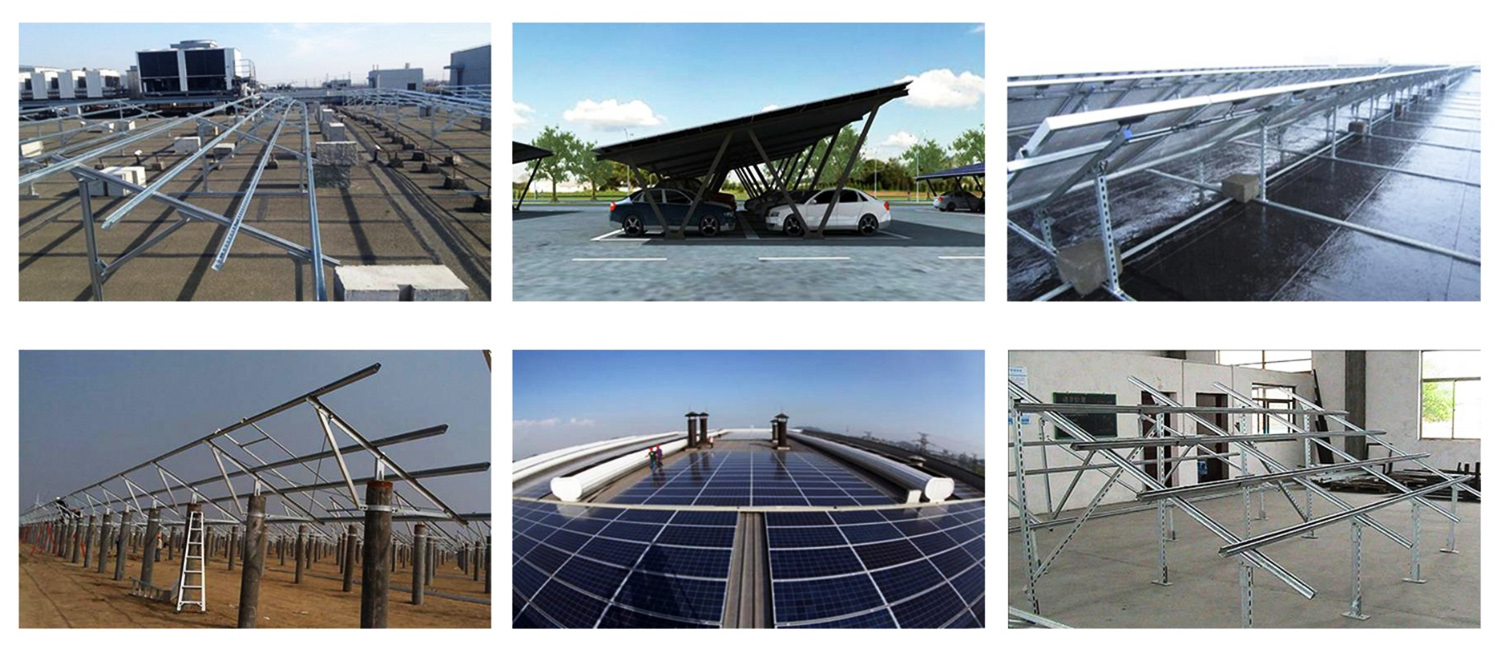

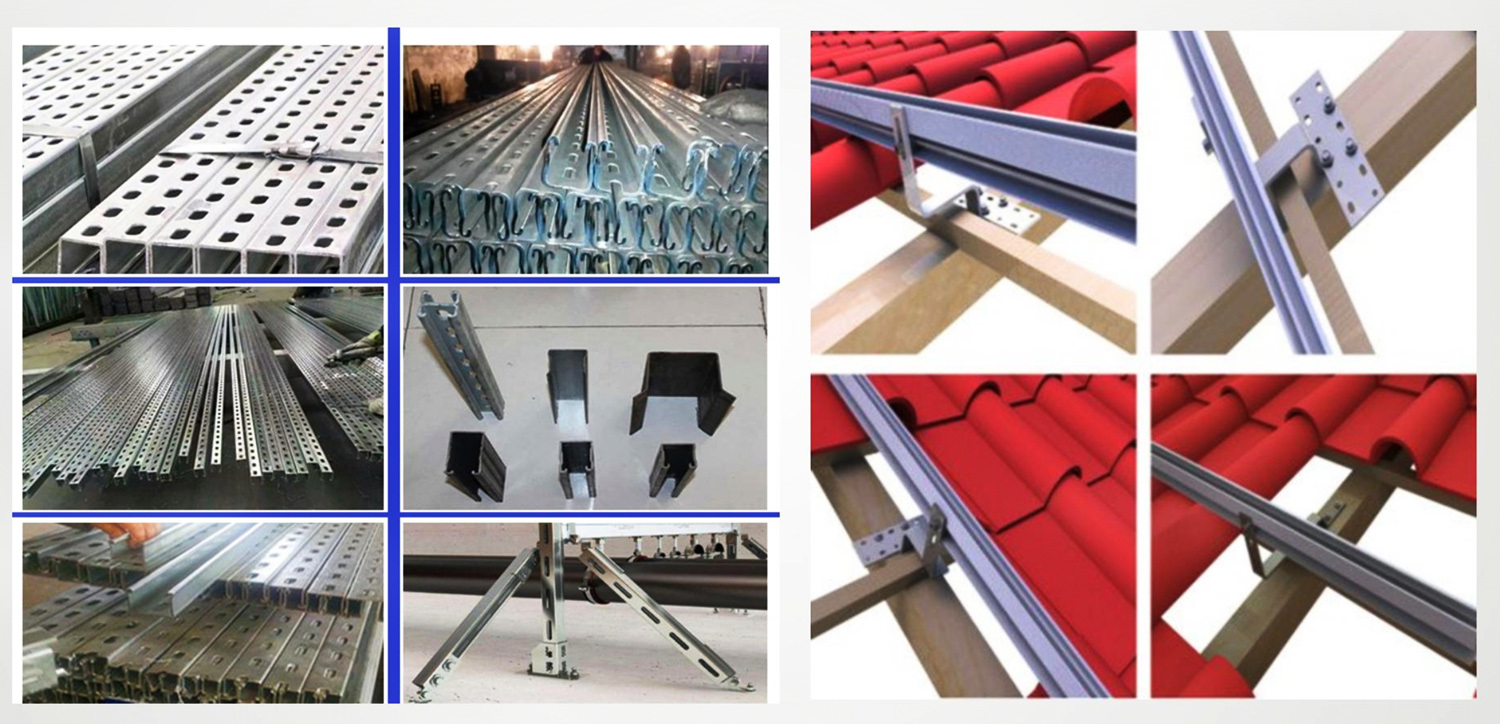

WORKPIECE

APPLICATION