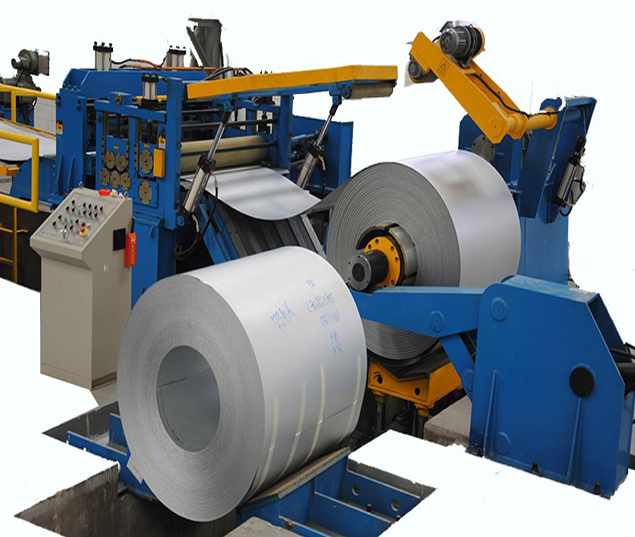

Stainless steel coils slitting machine line

PRODUCT DESCRIPTION

Feeding Trolley

Purpose: To position the coil set on the uncoiler drum.

Structure: The trolley is composed of a hydraulic lifting rack and a motorized traveling carriage.

Rack roller diameter 220mm, wrapped with polyester glue, with groove in the middle

The oil cylinder is lifted and lowered, and the four guide columns are guided.

The car disc is driven by the motor and moves along the rail.

The trolley has a cable and oil pipe protection drag chain.

Uncoiler + Reel Support

Uses: Automatic unwinding and unwinding or recycling of coils.

Structure: Single reel type.

The reel is a four-lobe type, which is hydraulically expanded and contracted. The expansion and contraction range of the body is Φ470-520mm, and the rubber boots with a thickness of 50mm are increased to 620mm.

The reel is driven by a DC motor through a gear box, and the motor generates uncoiling tension, the size of which is adjustable.

The main shaft of the reel is equipped with a butterfly pneumatic brake device, and the parking brake is provided.

The pressing roller is covered with rubber, the motor drives the rotation, and the oil cylinder swings to press the material head.

Slitting machine

Application: Cut the sheet into strips of various widths longitudinally.

Structure: Slider type for slitting production line.

The upper cutter shaft is installed on the lifting slider, the lower cutter shaft is fixedly installed in the frame, and the motor adjusts the distance between the upper and lower cutter shafts (the overlap of the upper and lower blades) through the turbine screw mechanism.

The cutter shaft is driven by DC motor, reducer, gear distribution box and universal joint

The cutter shaft is machine with several cutter discs and a series of spacers with different thicknesses, and the cutter discs and spacers are compressed by nuts.The tool shaft support is a welded part, one side is movable and the other side is fixed. When changing the tool, the moving support is pulled away by the screw rod along the base guide rail, and the tool shaft cantilever is supported on the fixed support.

Pre-separation machine for steel coil slitting line

Purpose: To separate the strips after slitting, to prevent stacking when passing through the tensioner, and to facilitate the collection.

Structure: Two sets of separation devices, one is installed at the entrance of the tension table, and the other is installed at the exit of the pit.

Winder + reel support

Purpose: To rewind the slitted strip.

Structure: It consists of a reel, a gear box, a pushing plate, a material-separating and pressing shaft, a transmission system and a reel support.

The reel is seamless, with jaws, hydraulic expansion and contraction. The range of expansion and contraction is Φ491-508 (perfect circle) mm.

The gear box is closed, with a two-stage reduction gear system installed inside, and the reel is installed on the box body through the main shaft.

The reel is driven by DC motor + pulley + gear box, and a pneumatic brake is installed on the output shaft of the motor.

The pushing plate is pushed by the oil cylinder to assist unloading.

Hydraulic swing of the material distribution and finalizer, to compress the tail material or separate and position the belt material, which is convenient for winding and tidy.

TECHNICAL PARAMETERS

| 1.Raw material parameters | |

| Material | ST37 (Q235) |

| Plate thickness | 1.0~ 4 mm |

| Material properties | Tensile strength σb≤470MPa Yield limit σs≤235MPa |

| Board width | 400~1500mm |

| Inner diameter of coil | Φ508mm/Φ610mm |

| Coil outer diameter | ≤Φ1800mm |

| Maximum coil weight | 15000kg |

| 2.Finished product parameters | |

| Strip inner diameter | Φ508mm/Φ610mm (plus rubber boots) |

| Strip outer diameter | ≤Φ1800mm |

| Maximum rewinding weight | 15000kg |

| Minimum strip width | ≥90mm |

| Width accuracy | 0.15mm |

| Shear burr | 5% plate thickness, |

| Strip straightness | 0.5mm/1000mm(genuine coil, width>100mm) |

| 3.Equipment parameters | |

| Number of slitting strips | 16 strips (thickness<2.5mm)10 strips (thickness<4mm) |

| Slitting speed | max100m/min |

| Total power | About 380KW |

| Production line area | 27mx12m (length x width) |

| 4.Energy medium requirements | |

| power supply: | Supply voltage: three-phase 380VVoltage fluctuation: ±5%

Frequency fluctuation: 50HZ±1% |

| Compressed air | Air supply pressure: 0.4~0.6Mpa (dry air source)Air supply: 500L/min |

| Hydraulic oil: | N46 anti-wear hydraulic oil. |