2022 High quality Drawer Channel Slide Roll Forming Machine - Auto U Beam Roll Forming Machine – Raintech

2022 High quality Drawer Channel Slide Roll Forming Machine - Auto U Beam Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Steel plate | Q345B 610L |

| Outer diameter of steel coil | ≤Ф1800 mm |

| Inner diameter of steel coil | Ф610mm |

| Steel belt width | Max 600mm |

| Strip thickness | 6~12mm |

| Single roll weight | ≤10000kg |

PRODUCTION PROCESS

The Production Line Is Carried Out According To The Following Process:

Uncoiling → Feeding And Leveling → Cutting, Pressing, Welding → Roll Forming → Cutting → Discharge

MAIN COMPONENTS

| Leading machine | 1 set |

| Uncoiler | 1set |

| Leveling | 1set |

| Shear butt welding | 1set |

| Forming Machine | 1set |

| Shearing machine | 1set |

| Discharge device | 1set |

1. Electrical control system

The whole line is controlled by Japan Mitsubishi PLC. The drive motor of the roll forming machine adopts a DC motor, which is controlled by an imported digital DC speed regulating device, with speed setting and fault alarm.

2. Hydraulic system

There are two hydraulic systems in the whole line, each with a set of welded oil tank, plunger pump, hydraulic valve block and valve block, oil filter, oil cooling system and pipeline.

1)The oil pump adopts the domestic famous brand CY series high pressure axial piston pump;

2)The valve block of this hydraulic system adopts a plate-type integrated structure;

3)The pressure control valve, direction control element, flow control element and other main control elements of this hydraulic system are all imported high-pressure products;

4)The oil cylinder adopts domestic high-quality brand-name products and imported seals to prevent system leakage

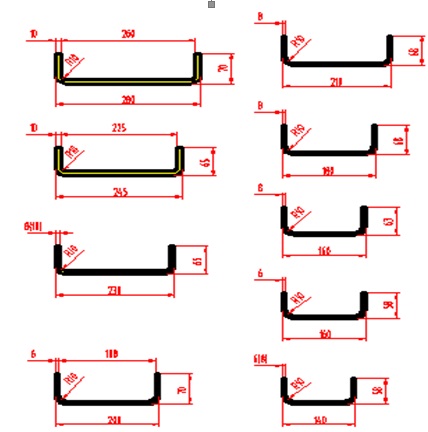

WORKPIECE SAMPLES

The u beam roll forming machine is mainly used to produce the steel structure of the bottom of the car.

APPLICATION

Automobile girder plates are mainly used to manufacture automobile longitudinal beams, cross beams, front and rear axles, bumpers and other structural parts.

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most competitive prices. So Profi Tools offer you best value of money and we are ready to develop together with 2022 High quality Drawer Channel Slide Roll Forming Machine - Auto U Beam Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Mauritania, Mali, St. Petersburg, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!