Products

-

Raintech Automatic Quickly Change Steel Frame Channel CZ Purlin Roll Forming Machine

Product Description

Production process flow

Uncoiling (including automatic feeding trolley) → leveling and guiding → quick-change roll forming (including straightening) → cutting.1. Uncoiling:

The machine is in single-head mode, single support and manual tightening.

2. Servo Leveling Feeder:

The machine adopts 5 rollers for leveling and feeding (2 rollers on the upper layer, 3 rollers on the lower layer, screw adjustment), 1 pair of guide rollers, the feeding rollers are pneumatically clamped, and the servo motor provides power for it.

3. Roll Forming Machine

Used to achieve the final required shape through the roll forming process of the required finished plate. The material is made of high-quality mold steel Cr12, and the hardness after quenching reaches HRC58~62 (physical characteristics are equivalent to American material D2), which improves mechanical performance and life. The surface of the roller is polished after finishing. The roller has high precision and long life.

4. Cutting

Structure: power saw head, servo tracking system, base, special fixtureProduct Parameters

Description of Machine component

Material Pregalvanized GI and CR Yield strength of raw materials 235Mpa Tensile strength of raw materials 550Mpa Coil OD ≤Ф1300 mm Coil ID Ф508mm Strip width ≤100mm Strip thickness ≤1~2.25mm Single roll weight ≤1000 kg Description of main electrical components

PLC Mitsubishi Inverter Delta Touch screen Vinylon (Taiwan, China) Low-voltage electrical appliances Sch neider (France) Encoder Omron (Japan) Servo controller Yaskawa (Japan) Product Detail

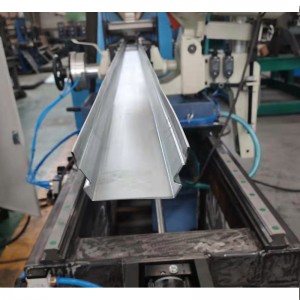

C-Shape Steel Forming

1. Corrugated steel culvert has both rigidity and flexibility; The structure has reasonable stress, uniform load distribution, and has a certain anti-deformation ability.

2. Adopt standardized design and mass production in the factory; Short production cycles and high efficiency are good for reducing costs and improving quality.

3. The site installation speed is fast, the construction period is short, and the social and economic benefits are obvious.

4, construction can be carried out throughout the year, the construction is not affected by the season and the environment.

5. It can effectively solve the problem of damage to concrete Bridges and culverts caused by repeated frost heave in cold areas of north China.

6. It is especially suitable for long-term use: eastern soil, expansive soil, soft soil, collapsible loess and other special areas, which can avoid the destruction of culvert caused by uneven settlement due to foundation deformation.

7. Reducing the use of conventional building materials such as cement, sand and stone has profound implications for environmental protection.Sample Display: C-Shape Steel

After Sales Service:

Our Service1. OEM DESIGN AND PRODUCTION:

Our Service1. OEM DESIGN AND PRODUCTION:Our active engineer and design team can make the special machine according to your special requirement.

2. DELIVERY IN TIME ASSURANCE:We assure the machines you ordered will be delivered at promised time

3. YOUR PAYMENT PROTECTION:You can pay through Alibaba to protect your advance payment

4. FREE INSTALLATION AND TRAINING:

We provide the installation and training by online video support; local installation and training service team; send engineer for installation and training, installation operation video providedCompany Profile:

Our workshop started since the year of 2008, built by a group of engineers, one of our founder member Mr. XU, who was worked as leader engineer for first-class roll forming department in SINOMRCH(China National Machinery Industry Corporation). After years of development, we have exported to many countries in the world such as Italy, Ecuador, America, India, Indonesia, Philipines, Brazil, Thailand, Vietnam, Russia, Malaysia, Peru, Korea etc., in order to service our clients overseas, we cooperate the local service agent to provide the after sale service; after more than ten years of running, we build the nice relationship with our clients and the local agent, those help us gain high reputation from our customers and the agents.

ENTERPRISE CERTIFICATE

INTERNATIONAL EXHIBITIONS

CUSTOMER VISITS

FAQ

♥1.How to operate the machine ?

We will deliver English manual and video with the machine to you. lf you still need our help,please contact us.♥2.If some problems happen to this machine during warranty period, what should I do?

We will supply free charge of spare parts and regularly maintenance service during machine warranty period if machine have some problems. So any doubts, just let us know, we will give you solutions.♥3.Does the machine can be customized according to my requirements ?

Yes, we have a strong technical team and have rich experience.♥4. What about the package and shipment ?

The machine will be packaged by multilayer plastic wrap for anti-humidity on the sea. The strong steel wire roops will be used for fix the machines in container to avoid any damage in transportation.

-

Raintech Best Price Hydraulic Metal Crash Barrier Making Machine

Product Description

This machine used for punching, forming and cutting of the highway guardrail corrugated plate, which widely used in bridge, highway construction, Power Culvert , highway culvert , infrastructure construction etc.

Product Parameters

MAIN PARAMETERS

Material Cold rolled mild steel Raw material yield strength 235~355Mpa Tensile strength of raw materials 420~550Mpa Coils OD ≤Ф1600 mm Coils ID Ф508mm Strips width ≤750mm Strips thickness 2.3~3mm Coils weight ≤10000 kg Line speed 4 pcs/min(Length4320mm) MAIN CONFIGURATION OF COMPONENTS

PLC Mitsubishi, Japan Servo system Yaskawa , Japan Transducer Delta (Taiwan) Touch Screen WEINVIEW(Taiwan) DC speed controller Eurotherm (USA) Encoder Omron Product Detail

WORKING PROCESSUncoiling—– servo leveling feeding—-looper(storage) —-400T multi-punching —–conveying roller —–roll forming—cutting —finished material discharging

1.We adopts individual archway stands for rollers station, more strong and rigidity structure than other suppliers in china.

2.Individual gearbox for each archway rollers set, to assure the precision of the profile.

3.All of the machine main body and parts are quenched, with higher hardness(HRC58-62) and wear resistance, while other suppliers only rough steel welded.

4.The rollers material is American D2 and D3 standards, with long service life and low maintenance cost.

5.Professional Germany roller design software-Copra.

6.Our price is most reasonable based on the top quality in this field.

7.Long machine life, all of our machines can be used stable performance for more than 10-15 year, while other small and low

quality supplier’s machine only can be used for 1-2 years. -

Raintech Hot Sale Perforated Steel Automatic Cable Tray Making Machine

Product Description

The production process:

Uncoiler→Leveler→Loop (storage)→Sevo Motor→multi-stations punching machine(cutting)→Finished Products

Product Parameters

Technical Parameter

No Model: SART-1250*2.5 Specification 1 Material CR/HR/G. I steel 2 Coil OD Ф1200 mm 3 Coil ID Ф508mm 4 Strips width <1250mm 5 Strips Thickness 0.5~2.5mm 6 Cable Tray Width 100~800mm 7 Cable Tray Height 50~200mm 8 Coils weight ≤10000 kg 9 Electrical power 415V,50Hz,3phase 10 Line Speed 5~15m/min Main Configuration ListNo Items Brand 1 PLC Mitsubishi(Japan) 2 Servo Controller Yaskawa(Japan) 3 Main Motor Siemens Baid 4 Frequency converter delta (Taiwan) 5 Touch screen weilun(china) 6 Low-voltage components Schneider(France) 7 Encoder Schneider(France) Product Detail

Machine Advantage1.We adopts individual archway stands for rollers station, more strong and rigidity structure than other suppliers in china.

2.Individual gearbox for each archway rollers set, to assure the precision of the profile.

3.All of the machine main body and parts are quenched, with higher hardness(HRC58-62) and wear resistance, while other suppliers only rough steel welded.

4.The rollers material is American D2 and D3 standards, with long service life and low maintenance cost.

5.Professional Germany roller design software-Copra.

6.Long machine life, all of our machines can be used stable performance for more than 10-15 year, while other small and low quality supplier’s machine only can be used for 1-2 years.

Sample Display

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc -

High Precision High Quality CZU Fast Change Roll Forming Machine

Production process flow

Uncoiling (including automatic feeding trolley) → leveling and guiding → quick-change roll forming (including straightening) → cutting.1. Uncoiling:

The machine is in single-head mode, single support and manual tightening.

2. Servo Leveling Feeder:

The machine adopts 5 rollers for leveling and feeding (2 rollers on the upper layer, 3 rollers on the lower layer, screw adjustment), 1 pair of guide rollers, the feeding rollers are pneumatically clamped, and the servo motor provides power for it.

3. Roll Forming Machine

Used to achieve the final required shape through the roll forming process of the required finished plate. The material is made of high-quality mold steel Cr12, and the hardness after quenching reaches HRC58~62 (physical characteristics are equivalent to American material D2), which improves mechanical performance and life. The surface of the roller is polished after finishing. The roller has high precision and long life.

4. Cutting

Structure: power saw head, servo tracking system, base, special fixtureProduct Parameters

Description of Machine component

Material Pregalvanized GI and CR Yield strength of raw materials 235Mpa Tensile strength of raw materials 550Mpa Coil OD ≤Ф1300 mm Coil ID Ф508mm Strip width ≤100mm Strip thickness ≤1~2.25mm Single roll weight ≤1000 kg Description of main electrical components

PLC Mitsubishi Inverter Delta Touch screen Vinylon (Taiwan, China) Low-voltage electrical appliances Sch neider (France) Encoder Omron (Japan) Servo controller Yaskawa (Japan) Detailed Photos

C-Shape Steel Forming

1. Corrugated steel culvert has both rigidity and flexibility; The structure has reasonable stress, uniform load distribution, and has a certain anti-deformation ability.

2. Adopt standardized design and mass production in the factory; Short production cycles and high efficiency are good for reducing costs and improving quality.

3. The site installation speed is fast, the construction period is short, and the social and economic benefits are obvious.

4, construction can be carried out throughout the year, the construction is not affected by the season and the environment.

5. It can effectively solve the problem of damage to concrete Bridges and culverts caused by repeated frost heave in cold areas of north China.

6. It is especially suitable for long-term use: eastern soil, expansive soil, soft soil, collapsible loess and other special areas, which can avoid the destruction of culvert caused by uneven settlement due to foundation deformation.

7. Reducing the use of conventional building materials such as cement, sand and stone has profound implications for environmental protection.Sample Display

C-Shape Steel

-

Raintech Hat Channel Roll Forming Machine Cold Rolled Bending Machine for Profiles

Production process flow

Uncoiling (including automatic feeding trolley) → leveling and guiding → roll forming (including straightening) → cutting.1. Uncoiling:

The machine is in single-head mode, single support and manual tightening.

2. Servo Leveling Feeder:

The machine adopts 5 rollers for leveling and feeding (2 rollers on the upper layer, 3 rollers on the lower layer, screw adjustment), 1 pair of guide rollers, the feeding rollers are pneumatically clamped, and the servo motor provides power for it.

3. Roll Forming Machine

Used to achieve the final required shape through the roll forming process of the required finished plate. The material is made of high-quality mold steel Cr12, and the hardness after quenching reaches HRC58~62 (physical characteristics are equivalent to American material D2), which improves mechanical performance and life. The surface of the roller is polished after finishing. The roller has high precision and long life.

4. Cutting

Structure: power saw head, servo tracking system, base, special fixtureDetailed Photos:

-

Raintech High Quality Ss Square Tube Mill Line Stainless Steel Tube Mill Pipe Making Machine

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishingEQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes.

-

Raintech Metal Sheet Panel Profile Standing Seam Steel Roofing Seaming Form Machine

Product Description

Glazed tile roll forming machine is used to produce metal glazed tile, step tile, roof tile, and corrugated tile, etc.

The metal roof tiles which produced by our machine are most notable for their toughness being virtually maintenance free.The metal roof tiles most time apply as roofing on villas , some residential buildings and industrial buildings.

Machine Application

The products are widely used in power plants, electric equipment companies, automobile exhibition halls, steel structure workshops, cement warehouses, steel structure offices, airport terminal buildings, railway stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, and Olympic venues. Stadiums and other steel structures.

Product Parameters

Material :Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MACHINE COMPONENTSNo Items Name Specifications 1 Decoiler Single head mode, single support

Coil ID: Ф508

Coil OD: Ф1300mm

Strips width: 1450 mm

Max. weight: ≤10000 kg2 Roll Forming Machine Structure: the forming unit is driven by motor reducer chain

Forming stations:36 stations

Forming machine shaft dia:φ95mm

Motor power: 22kwX2

Max.: 15m/min3 Hydraulic Cutting The cutter mode adopts blanking shearing

Blade material :Cr12MoV (hardness after quenching HRC58~62)

Parameter :cutting accuracy:±1.5mm4 Electrical Control Cabinet Main electrical components:

PLC: Mitsubishi

Inverter: delta

Touch screen: veron (Taiwan, China)

Low-voltage electrical appliances: schneider (France)

Encoder: Omron (Japan)5 Hydraulic System Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade 6Run-out Table Size:3*1.2*0.6m

Adjustable Height -

Raintech Automatic Tube Erw Welded Pipe Tube Mill Manufacturer

EQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes.Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishingTECHNICAL PARAMETERS

Main technical performance parameters of the machine:No Project Reachability Indicators 1 Effectively polished diameter(mm) 19-76mm 2 Effectively polished length (mm) 6000 3 Final surface roughness Ra 0.1(Through surface friction many times) 4 Dust emission treatment Meet national standards (optional) Work environment requirements:

1 working environment temperature 0-60ºC 2 Relative humidity <90% 3 power supply voltage AC three-phase 380V 4 Power Frequency 50HZ 5 input power <10KW Model List

-

Professional Manufacture Tile Sheet Truck Container Making Carriage Board Car Panel Roll Forming Machine

Brief Introduction

The carriage board production line equipment is an automatic equipment, used for making carriage top, bottom, and side plate” of truck carriage plate

Production process

The production line is carried out according to the following process:

Uncoiling → Leveling → Looper (Storage) → Servo Feeding, Pre-cutting → Looper (Storage) →roll forming → Spot Welding→cutting→discharging.

-

Raintech Automatic Stainless Steel Pipe Making Machine ERW Tube Mill Machine

Product Description

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishingEQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes. -

Raintech High Quality SS Square Tube Mill Line

Product Description PROCESSING OBJECTS AND REQUIREMENTS

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishing

EQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes. -

Raintech Fully Automatic Pre-Galvanized Cable Tray Roll Forming Machine

Product DescriptionOur cable tray roll forming machine is highly integrated by uncoiling ,leveling,forming ,cutting off,punching,receiving and related process.The whole production line is controlled by PCL program . Operators can select a preset program to run the whole line automatically by using touch screen.The methods of operation include automatic control ,manual control,separate operation and emergency stop .

Working ProcessUncoiler→Leveler→Loop (storage)→Sevo Motor→Multi-Stations Punching Machine(cutting)→Finished Products

Our Advantages

Our Advantages1.We adopts individual archway stands for rollers station, more strong and rigidity structure than other suppliers in china.

2.Individual gearbox for each archway rollers set, to assure the precision of the profile.

3.All of the machine main body and parts are quenched, with higher hardness(HRC58-62) and wear resistance, while other suppliers only rough steel welded.

4.The rollers material is American D2 and D3 standards, with long service life and low maintenance cost.

5.Professional Germany roller design software-Copra.

6.Long machine life, all of our machines can be used stable performance for more than 10-15 year, while other small and low quality supplier’s machine only can be used for 1-2 years.

7.We have a professional designer and experienced engineer team and the raw material and accessories we use are good.

8.we provide the technical support for whole life of our machines.

9.within one year since the date of finishing commissioning. The guarantee covers all the electric, mechanic and hydraulic parts in the line except for the easy-worn parts. Application

ApplicationThis cable tray roll forming machine is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc.