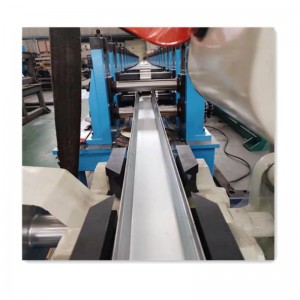

Roof plate roll forming machine

-

Raintech Metal Sheet Panel Profile Standing Seam Steel Roofing Seaming Form Machine

Product Description

Glazed tile roll forming machine is used to produce metal glazed tile, step tile, roof tile, and corrugated tile, etc.

The metal roof tiles which produced by our machine are most notable for their toughness being virtually maintenance free.The metal roof tiles most time apply as roofing on villas , some residential buildings and industrial buildings.

Machine Application

The products are widely used in power plants, electric equipment companies, automobile exhibition halls, steel structure workshops, cement warehouses, steel structure offices, airport terminal buildings, railway stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, and Olympic venues. Stadiums and other steel structures.

Product Parameters

Material :Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MACHINE COMPONENTSNo Items Name Specifications 1 Decoiler Single head mode, single support

Coil ID: Ф508

Coil OD: Ф1300mm

Strips width: 1450 mm

Max. weight: ≤10000 kg2 Roll Forming Machine Structure: the forming unit is driven by motor reducer chain

Forming stations:36 stations

Forming machine shaft dia:φ95mm

Motor power: 22kwX2

Max.: 15m/min3 Hydraulic Cutting The cutter mode adopts blanking shearing

Blade material :Cr12MoV (hardness after quenching HRC58~62)

Parameter :cutting accuracy:±1.5mm4 Electrical Control Cabinet Main electrical components:

PLC: Mitsubishi

Inverter: delta

Touch screen: veron (Taiwan, China)

Low-voltage electrical appliances: schneider (France)

Encoder: Omron (Japan)5 Hydraulic System Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade 6Run-out Table Size:3*1.2*0.6m

Adjustable Height -

Hot Selling Glazed Steel Roof Tile Sheets Roll Forming Making Machine Line

The metal roof tiles which produced by our machine are most notable for their toughness being virtually maintenance free.The metal roof tiles most time apply as roofing on villas , some residential buildings and industrial buildings. -

Hat Shape Profile Roll Forming Machine

GENERAL INTRODUCTION: Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive. 1 Machine structure Individual archway stands structure 2 Total power Motor power-18.5kw Hydraulic power-5.5kw 3 Roller stations 18 dots stations 4 Productivity 15-25m/min 5 Decoiler 3T hydraulic decoiler 6 Lev... -

Double Deck Roofing Sheet Roll Forming Machine

Floor decking roll forming machine is manually used to produce steel floor decking and can produce high quality floor decking has advantages, such as no cutting deformation, high strength and a large working load. It can be directly mixed with the steel mesh and concrete with good adhesion. The main applications of decking sheets include thermal power plant, multilayer car shade parking, multi-story residential and commercial buildings such as shopping malls, bridges, platforms, walkways, mezzanines, silos, etc.

-

Best Selling Cable Tray Roll Forming Machine

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc

-

C U Z Purlin Roll Forming Machine

This line can produce C Z U and L shape metal profile on one machine, through only need to change some rollers.The uncoiler also contains 4 baffle plates to avoid the material from loosing during uncoiling.Main frame material:400# steel, thickness of Middle plate is 25mm. The main frame of machine is welded separately and the outside wall is connected by screw after being shot blasted on the surface. there are two purpose of being shot blasted: one, derusting. Two surface strengthening.

-

Cable Tray Roll Forming Production Line

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories.

This production line is mainly composed by following parts:

1. Uncoiler. Single support,four-bar tension structure, tension force comes from hydraulic cylinder, adjustment is fast and reliable.2. Leveler. It adopts 7 rollers for leveling, 2 pairs of guide rollers, feed rollers are pneumatically clamped, frequency conversion speed regulation, switch control.3. Looper ( Storage Material) Used to buffer the speed mismatch between the unwinding and leveling and the punching machine, and correct the deviation;4. Servo Feeder. The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick

5. Multi-stations Punching&Cutting Unit. It adopts liquid four-column press mode, which is economical, applicable and fast. The punching machine has a 6-station punching mode and contains 3 to 4 sets of die sets, which can continuously punch out multiple types of holes.6. Cantilever adjustable forming machine . The forming unit adopts the cantilever forming machine mode. Motor, reducer, spiral bevel gear drive.When producing products with different bottom widths and waist heights, you only need to set the parameters on the touch screen, which is convenient, fast and reliable. -

Hat Profile Roll Forming Machine

Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive.

-

Color plate glazed tile 3d cutting automatic forming machine

The glazed tile roll forming machine is used to produce glazed tiles. Components: The glazed tile glazed tile forming machine is composed of charging rack, charging rack support, feeding guide device, forming host, punching device, forming shearing device, hydraulic station, computer control cabinet and other parts from the external structure. .The glazed tiles formed by the rolling die of this machine have the characteristics of beautiful appearance, simple and elegant, exquisite shape and noble taste, etc. They can be widely used in garden-style factories, tourist scenic spots, pavilions, hotels, villas, exhibition halls, resorts, etc. Home and other buildings and outdoor decoration

-

C Z U Inner change Roll forming Machine Line

Our advanced design for C Z metal profile is our star products.It have the feathures of can exchange the C and Z profile without changing the rollers. The machine can do both profiles on same machine without any cost increase. In addition, if customer require, we can add U on same machine, only need change part of rollers. This machine can do three products , instead of three separated machines . Its the most economic and reasonable design which is used widely in construction purlin, C post and other application in construction work.

-

Pu sandwich panel roll forming production line

Pu sandwich panel roll forming production line is made of high quality color steel plate and light inner core material, through the special composite production line made of one or two sides of the outer layer, forming a high strength, light weight, good heat insulation effect of a new type of construction and decoration materials.

-

light steel keel roll forming production line

This machine is a light steel keel production line used to produce “villa keel”. The light steel villa forming machine reads the complete set of keel component structure designed by Vertex BD software from the U disk, and laps them together to form a complete light steel villa frame.