Tube Mill Line

-

Raintech High Quality Ss Square Tube Mill Line Stainless Steel Tube Mill Pipe Making Machine

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishingEQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes.

-

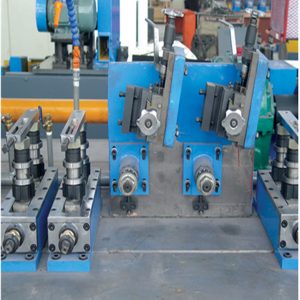

Raintech Automatic Tube Erw Welded Pipe Tube Mill Manufacturer

EQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes.Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishingTECHNICAL PARAMETERS

Main technical performance parameters of the machine:No Project Reachability Indicators 1 Effectively polished diameter(mm) 19-76mm 2 Effectively polished length (mm) 6000 3 Final surface roughness Ra 0.1(Through surface friction many times) 4 Dust emission treatment Meet national standards (optional) Work environment requirements:

1 working environment temperature 0-60ºC 2 Relative humidity <90% 3 power supply voltage AC three-phase 380V 4 Power Frequency 50HZ 5 input power <10KW Model List

-

Raintech Automatic Stainless Steel Pipe Making Machine ERW Tube Mill Machine

Product Description

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishingEQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes. -

Raintech High Quality SS Square Tube Mill Line

Product Description PROCESSING OBJECTS AND REQUIREMENTS

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishing

EQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes. -

High Quality 32mm Stainless Steel Tube Mill line

Stainless steel tube mill line, referred to as welded pipe, is a steel pipe made of commonly used steel or steel strip after crimping and forming by the unit and mold. The production process of welded steel pipe is simple, the production efficiency is high, there are many varieties and specifications, and the investment in equipment is small, but the general strength is lower than that of seamless steel pipe. The production line is designed and manufactured on the basis of digesting and absorbing similar equipment at home and abroad, combining with my country’s national conditions, boldly innovating, and listening to users’ opinions extensively. The equipment is economical, reliable and stable.

-

High Frequency Tube Welding Mill Line

High frequency straight seam welded pipe production line is mainly used to produce electric welded steel pipes with φ60~φ219mm and wall thickness of 2.0~6.0mm, and can also produce square and rectangular pipes and special-shaped pipes not exceeding the range of round pipes. API 5L tubes can be produced later by adding necessary equipment. The production line is designed and manufactured on the basis of digesting and absorbing similar equipment at home and abroad, combining with my country’s national conditions, boldly innovating, and listening to users’ opinions extensively. The equipment is economical, reliable and stable.

-

High Quality ERW Tube Mill line

High frequency straight seam welded pipe production line is mainly used to produce electric welded steel pipes with φ60~φ219mm and wall thickness of 2.0~6.0mm, and can also produce square and rectangular pipes and special-shaped pipes not exceeding the range of round pipes. API 5L tubes can be produced later by adding necessary equipment. The production line is designed and manufactured on the basis of digesting and absorbing similar equipment at home and abroad, combining with my country’s national conditions, boldly innovating, and listening to users’ opinions extensively. The equipment is economical, reliable and stable

-

High Precision Tube Mill Production line

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The equipment is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishing

EQUIPMENT MAIN STRUCTURE AND PROPERITIES

The equipment mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece

receiving (releasing) mechanism, a set of dust removal system (optional).

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding

characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is

transmitted to the turnable through the V-belt to directly drive the turntable to rotate.It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic

control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing.It consists of roller, feeder ,backlash adjusting screw and motor drive

system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing.It consists of adjusting screw, rubber wheels and pallet.

6.Dust removal system (optional):

The role of this system is to collect the dust generated during the grinding process, to solve the dust collection, easy maintenance

and cleaning. It is mainly composed of a cyclone dust collector, a bag vacuum cleaner, and dust collection pipes. TECHNICAL PARAMETERS

Main technical performance parameters of the machine:No Project Reachability Indicators 1 Effectively polished diameter(mm) 19-76mm 2 Effectively polished length (mm) 6000 3 Final surface roughness Ra 0.1(Through surface friction many times) 4 Dust emission treatment Meet national standards (optional) Work environment requirements:

-

76mm Tube Mill Line Pipe Mill Line

High frequency welding is used in the production of steel welded pipes. High frequency welding has larger power supply, and higher welding speed can be achieved for steel pipes with different material, caliber and wall thickness.

-

Tube and Pipe Mills High Frequency Welding Production Line

The tube mill line mainly consists of one set of grinding head, a set of planetaryrotation system, a set of electrical control, a set of feeding system, a set of workpiece receiving (releasing) mechanism, a set of dust removal system (optional).

-

Straight Seam Steel Welded Steel Tube Mill Line

The tube milling line is straight seam welding on welding equipment from steel pipes made of hot-rolled or cold-rolled steel sheets or coils.