Cheapest Price Welded Tube Mill Machine - Tube and Pipe Mills High Frequency Welding Production Line – Raintech

Cheapest Price Welded Tube Mill Machine - Tube and Pipe Mills High Frequency Welding Production Line – Raintech Detail:

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The tube mill line is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishing.

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

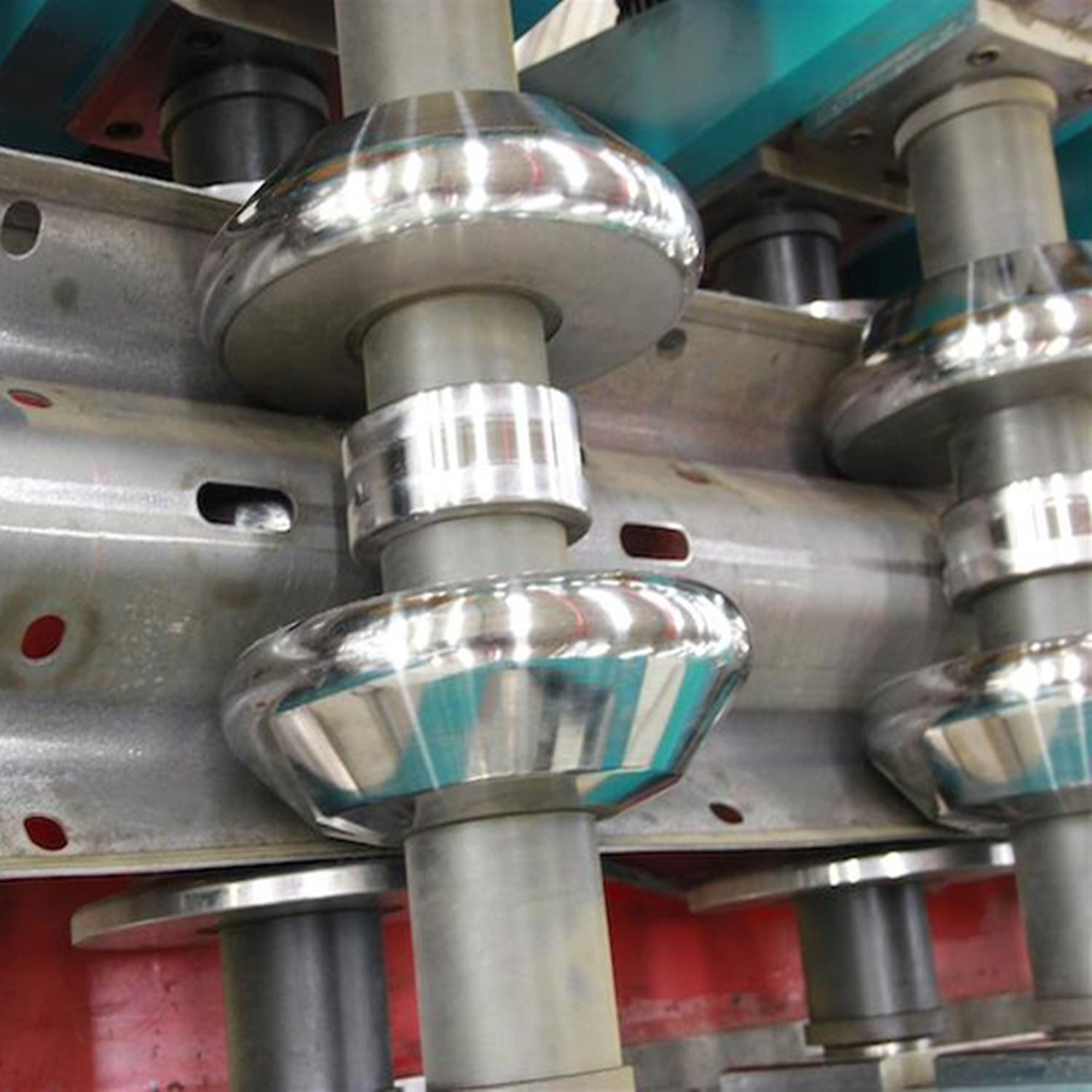

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is transmitted to the turnable through the V-belt to directly drive the turntable to rotate. It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing. It consists of roller, feeder ,backlash adjusting screw and motor drive system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing. It consists of adjusting screw, rubber wheels and pallet

TECHNICAL PARAMETERS

Main technical performance parameters of the machine

|

No |

Project |

Reachability Indicators |

|

1 |

Effectively polished diameter(mm) |

19-76mm |

|

2 |

Effectively polished length (mm) |

6000 |

|

3 |

Final surface roughness |

Ra 0.1(Through surface friction many times) |

|

4 |

Dust emission treatment |

Meet national standards (optional) |

MAIN COMPONENTS AND ACCESSORIES MANUFACTURER

|

NO. |

Components |

|

|

|

1 |

Grinding head |

1 Set |

ADV Polishing |

|

2 |

Planetary rotation system |

1 Set |

ADV Polishing |

|

3 |

electric control system |

1 Set |

ADV Polishing |

|

4 |

Dust removal system (optional) |

1 Set |

ADV Polishing |

|

5 |

Workpiece receiving (releasing) mechanism |

1 Set |

ADV Polishing |

|

6 |

Feeding system |

1 Set |

ADV Polishing |

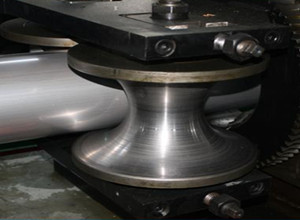

DETAILS SHOW

Product detail pictures:

Related Product Guide:

We are experienced manufacturer. Wining the majority from the crucial certifications of its market for Cheapest Price Welded Tube Mill Machine - Tube and Pipe Mills High Frequency Welding Production Line – Raintech , The product will supply to all over the world, such as: Lithuania, Vietnam, Amsterdam, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!