China wholesale Tube Mill - Tube and Pipe Mills High Frequency Welding Production Line – Raintech

China wholesale Tube Mill - Tube and Pipe Mills High Frequency Welding Production Line – Raintech Detail:

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The tube mill line is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishing.

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is transmitted to the turnable through the V-belt to directly drive the turntable to rotate. It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing. It consists of roller, feeder ,backlash adjusting screw and motor drive system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing. It consists of adjusting screw, rubber wheels and pallet

TECHNICAL PARAMETERS

Main technical performance parameters of the machine

|

No |

Project |

Reachability Indicators |

|

1 |

Effectively polished diameter(mm) |

19-76mm |

|

2 |

Effectively polished length (mm) |

6000 |

|

3 |

Final surface roughness |

Ra 0.1(Through surface friction many times) |

|

4 |

Dust emission treatment |

Meet national standards (optional) |

MAIN COMPONENTS AND ACCESSORIES MANUFACTURER

|

NO. |

Components |

|

|

|

1 |

Grinding head |

1 Set |

ADV Polishing |

|

2 |

Planetary rotation system |

1 Set |

ADV Polishing |

|

3 |

electric control system |

1 Set |

ADV Polishing |

|

4 |

Dust removal system (optional) |

1 Set |

ADV Polishing |

|

5 |

Workpiece receiving (releasing) mechanism |

1 Set |

ADV Polishing |

|

6 |

Feeding system |

1 Set |

ADV Polishing |

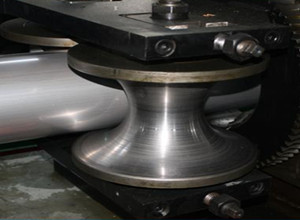

DETAILS SHOW

Product detail pictures:

Related Product Guide:

Our enterprise aims to operating faithfully, serving to all of our prospects , and working in new technology and new machine frequently for China wholesale Tube Mill - Tube and Pipe Mills High Frequency Welding Production Line – Raintech , The product will supply to all over the world, such as: Singapore, Kuala Lumpur, Costa rica, Our company absorbs new ideas, strict quality control, a full range of service tracking, and adhere to make high-quality products. Our business aims to "honest and trustworthy, favorable price, customer first", so we won the trust of the majority of customers! If you are interested in our products and services, please do not hesitate to contact us!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.