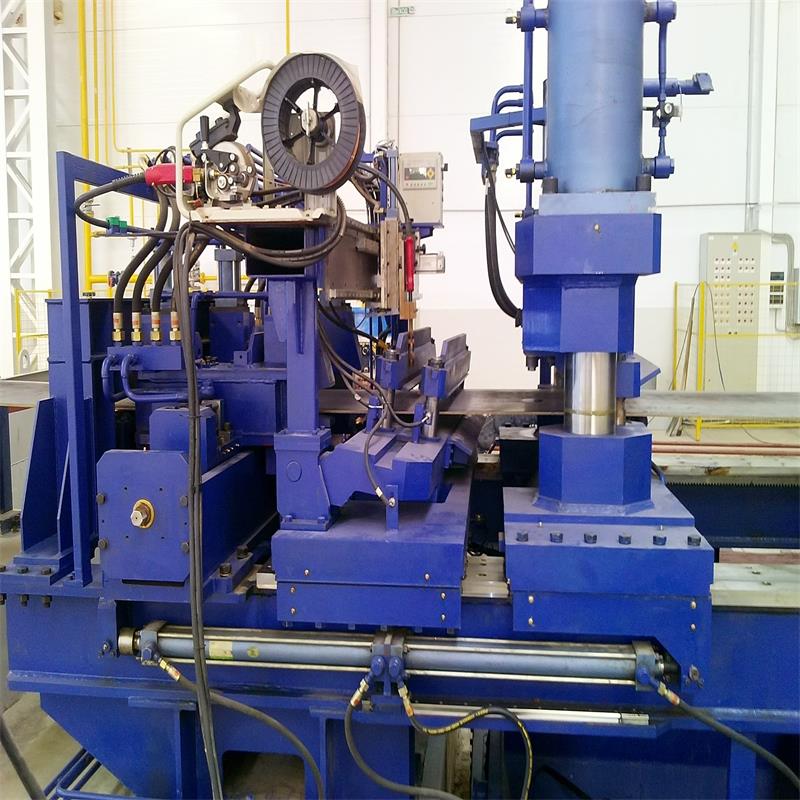

Chinese Professional Metal Roof Tile Making Machine - Culvert Corrugated Plate Roll Forming Machine – Raintech

Chinese Professional Metal Roof Tile Making Machine - Culvert Corrugated Plate Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| No | Model | Specification |

| 1. | Material | Hot rolled steel plate |

| 2. | Yield strength of raw material | ≤345Mpa |

| 3. | Tensile strength of raw materials: | ≤550Mpa |

| 4. | Coiling material outside diameter | ≤Ф1500 mm |

| 5. | Inner diameter of coil | Ф610 |

| 6. | Width of steel belt | ≤1550mm |

| 7. | Thickness of steel belt | 8~12mm |

| 8. | Single roll weight | ≤20000 kg |

MAIN COMPONENTS

| No | Items Name | Specifications |

| 1 | Auto Decoiler | 1. Single head mode, single support 2.Coil ID: Ф610 3. Coil OD: Ф1500mm 4. Strips width: 1700 mm 5. Max. weight: ≤20000 kg |

| 2 | Leveling Machine | Max. Working Speed: 15m/min Max. Strips width: 1700 mm Max. Material thickness: 8mm Motor Power: About 30kw |

| 3 | Shear butt welding device | The frame is a profile + steel plate welding structure, hydraulic shearing, hydraulic pressing, and pressing platform |

| 4 | Servo Feeding | 1. Maximum feeding speed: 15m/min 2. The maximum allowable feeding width: ≤1700mm 3. Allowable feeding thickness: ≤8mm 4. Single feeding error: ≤±1mm (the tolerance is not cumulative) 5. Servo motor power: ≈15Kw (subject to the final design) 6. The material of the feeding roller is: 9Cr2Mo (or GCr15), hardness HRC55-60 |

| Punching Press | Adopt liquid four-column press mode Punching Press: 500T Hole Size:15-φ25 |

|

| 5 | Roll Forming Machine | Structure: the forming unit is driven by motor reducer chain Forming stations: 24 stations Forming machine shaft dia: φ180mm Motor power: 180kw Max.: 2-8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing Blade material: Cr12MoV (hardness after quenching HRC58~62) Parameter: cutting accuracy:±1.5mm |

| 7 | Electrical Control Cabinet | Main electrical components: PLC: Mitsubishi Inverter: delta Touch screen: veron (Taiwan, China) Low-voltage electrical appliances: schneider (France) Encoder: Omron (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

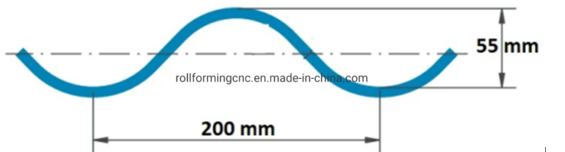

WORKPIECE SAMPLES

The culvert corrugated plate is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

APPLICATION

The culvert corrugated board production line is a special equipment for culvert corrugated board compression molding, which is widely used in construction industry and other facilities, including railway bridge tunnels, highway bridge tunnels etc.

Product detail pictures:

Related Product Guide:

No matter new consumer or outdated shopper, We believe in lengthy expression and trusted relationship for Chinese Professional Metal Roof Tile Making Machine - Culvert Corrugated Plate Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Cyprus, Hanover, Kenya, Till now, the goods list has been updated regularly and attracted clients from around the globe. Detailed facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are going to help you get comprehensive acknowledge about our products and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.

Write your message here and send it to us