Factory best selling Roof Tile Roll Forming Machine - Rain Downspout Roll Forming Machine – Raintech

Factory best selling Roof Tile Roll Forming Machine - Rain Downspout Roll Forming Machine – Raintech Detail:

PRODUCT DESCRIPTION

Downspout roll forming production line is made of colored steel or aluminum plate through roller pressing, closed molding, through bending with equipment, shrinkage molding, simple design, simple installation, widely used in modern villas and multi-storey buildings.

MAIN TECHNICAL PARAMETERS

Material: Galvanized Steel

Material thickness: 0.5~0.6mm

Percentage of elongation: ≥2%

Yield strength of material: 550MPa

Material tensile strength: 450 MPa

Coil weight: ≤4ton

Coil ID: 508mm

Coil width: ≤550mm

MAIN COMPOSITIONS

1. UNCOILER.

The uncoiler is a simple manual uncoiler for supporting the material

2. ROLL FORMING MACHINE.

Used to roll the required finished plate shape to the final required cross-sectional shape through the roll forming process.

Main Parameters:

Main machine length: 11600mm×1100mm×1300mm

Feeding device: Feed platform and adjustable guide device

Transmission: chain wheel/gear

Forming rollers tunnel: 21 dots

Rollers material: 45# steelHard Chrome Plating

Shaft diameter: ф75mmhigh precision machining

Forming speed: aprox.15m/min.

Main Motor: aprox.11KW Planetary cycloidal reducer

1. SAW BLADE CUTTING.

It is to cut the formed parts to length

Main Parameter:

Mainly composed of shearing frame, cutting die, hydraulic system, base.

Cutter material: Cr12MoV (hardness after quenching is HRC58~62)

Cutting method: stop cutting

Oil pump motor: aprox.4KW

fixed-length accuracy: ±1mm

1. ELECTRICAL CONTROL UNIT.

The whole line adopts the man-machine control mode combining PLC and touch screen. The specification parameters, quantity and system parameters of the parts can be set through the touch screen.

2. HYDRAULIC STATION.

Adopt the combination structure of pump and accumulator, fast blanking and shearing speed, improve the speed of production line.The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic tank

Hydraulic station: 15kw

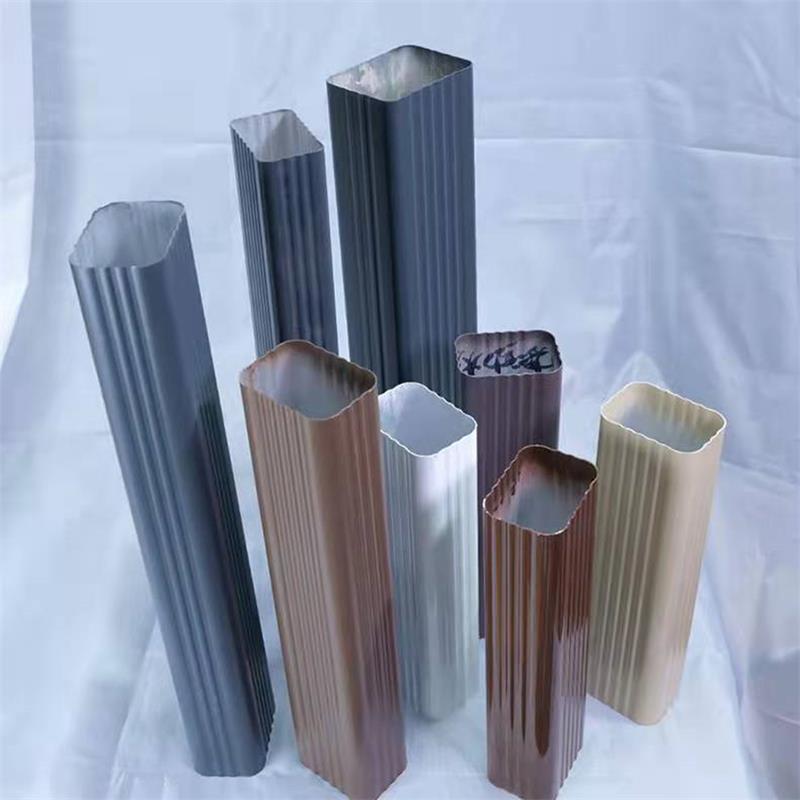

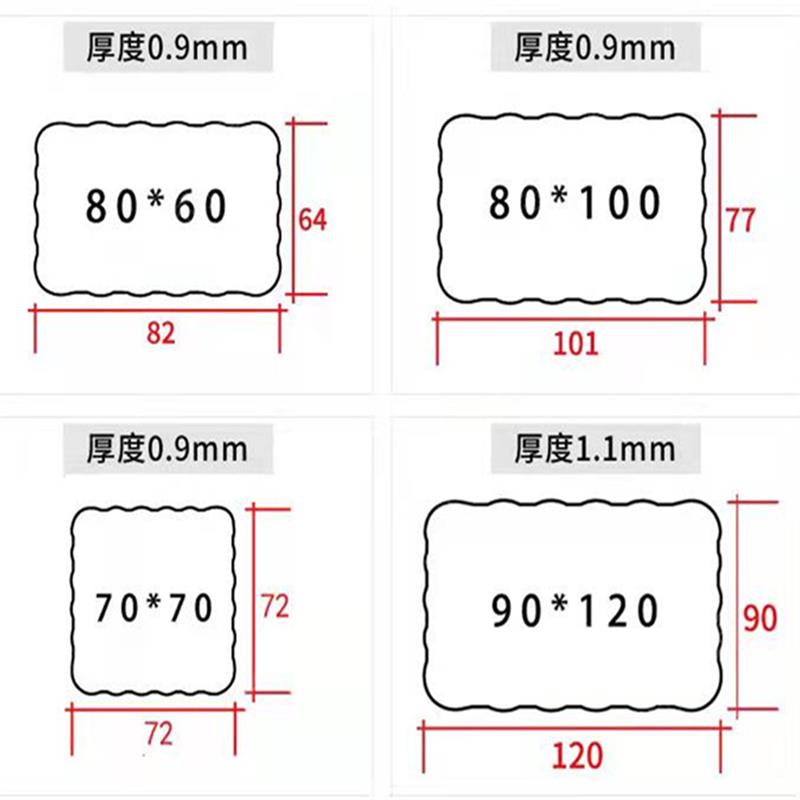

FINISHED SQUARE DOWNSPOUT SHOW

Rain gutter roll forming machine; downpipe roll forming machine; downspout making equipment;rain gutter making machine.

Product detail pictures:

Related Product Guide:

We continue to keep increasing and perfecting our solutions and service. At the same time, we operate actively to do research and enhancement for Factory best selling Roof Tile Roll Forming Machine - Rain Downspout Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Danish, Czech Republic, Turin, We follow superior mechanism to process these products that ensure optimum durability and reliability of the products. We follow latest effective washing and straightening processes that allow us to offer unmatched quality of products for our clients. We continually strive for perfection and all our efforts are directed towards attaining complete client satisfaction.

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.