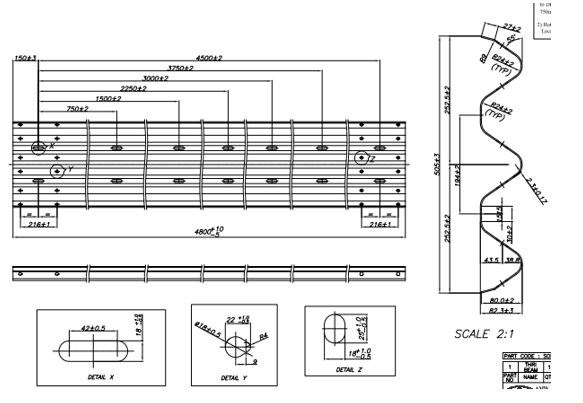

Factory directly supply Puf Panel Machine Price - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech

Factory directly supply Puf Panel Machine Price - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Material | Cold rolled low carbon steel |

| Server system | YASKAWA |

| Steel belt width | ≤750mm |

| Production line speed | 15m/min |

| Electric control unit | PLC(Mitsubishi) |

MAIN COMPONENTS

1. Uncoiler

The machine is a single-head mode. With single support, the motor drives the material shaft of the uncoiler to release the material roll, and the hydraulic power drives the tension device of the material shaft of the uncoiler to fix the material roll on the material shaft of the uncoiler.

2. Uncoiler Parameter

| Allowable coil inner diameter | Ф508mm |

| Maximum allowable roll diameter | Ф1600mm |

| Maximum allowable roll width | 500 mm |

| Maximum roll carrying weight | ≤5000 kg |

| Uncoiler motor power | ≈5.5Kw (subject to the final design) |

3. Leveling Servo Feeder

The front of the leveling machine is also equipped with a telescopic shovel head and a material pressing device to ensure that the raw material rolls enter the leveling machine smoothly and safely.

| Maximum working speed | 40 m/min |

| Maximum leveling roll width | 500mm |

| Adapt to the maximum roll thickness | 2mm |

| Motor power of leveling machine: | ≈7.5Kw(subject to the final drawing design) |

4. Roller Forming Machine

The forming unit adopts an independent frame (housing mode). Motor, reducer drive, gear and chain drive.

| Forming Passes | about 13 |

| Shaft diameter of forming machine | φ80mm(subject to the final design) |

| Motor Power | about 55W(subject to the final design |

| Max. speed | 10~15m/min |

WORKPIECE SAMPLES

This is a 3 wave barrier made by our production equipment.

APPLICATION

Guardrails are widely used in industry, agriculture, municipal administration, transportation and other industries for decoration, maintenance and protection.

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and advancement, we will build a prosperous future with each other with your esteemed firm for Factory directly supply Puf Panel Machine Price - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Jakarta, Cyprus, Sweden, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.