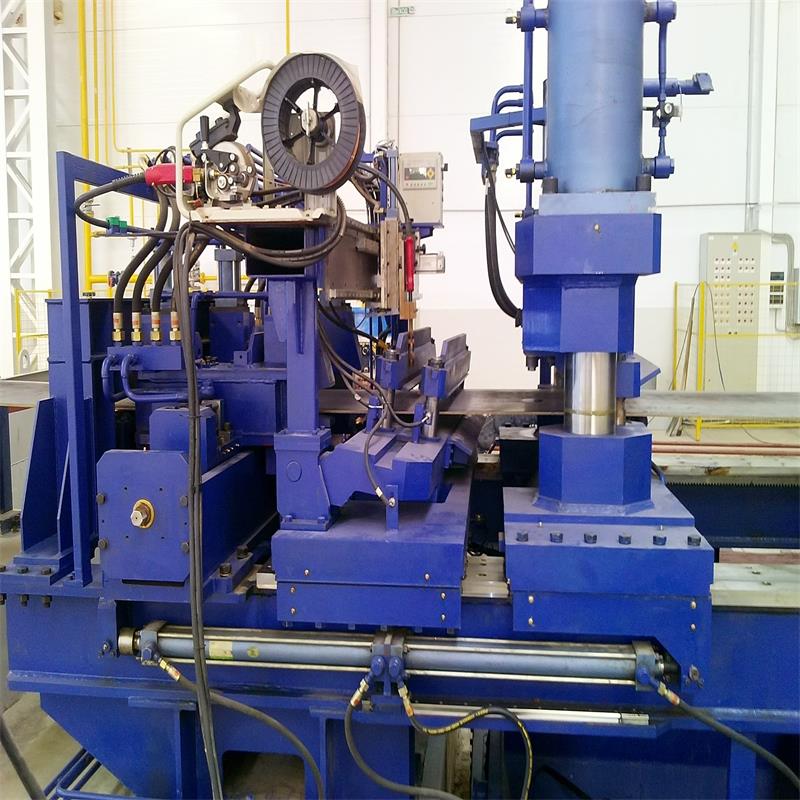

Factory made hot-sale Shelf Roll Forming Machine - Culvert Corrugated Plate Roll Forming Machine – Raintech

Factory made hot-sale Shelf Roll Forming Machine - Culvert Corrugated Plate Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| No | Model | Specification |

| 1. | Material | Hot rolled steel plate |

| 2. | Yield strength of raw material | ≤345Mpa |

| 3. | Tensile strength of raw materials: | ≤550Mpa |

| 4. | Coiling material outside diameter | ≤Ф1500 mm |

| 5. | Inner diameter of coil | Ф610 |

| 6. | Width of steel belt | ≤1550mm |

| 7. | Thickness of steel belt | 8~12mm |

| 8. | Single roll weight | ≤20000 kg |

MAIN COMPONENTS

| No | Items Name | Specifications |

| 1 | Auto Decoiler | 1. Single head mode, single support 2.Coil ID: Ф610 3. Coil OD: Ф1500mm 4. Strips width: 1700 mm 5. Max. weight: ≤20000 kg |

| 2 | Leveling Machine | Max. Working Speed: 15m/min Max. Strips width: 1700 mm Max. Material thickness: 8mm Motor Power: About 30kw |

| 3 | Shear butt welding device | The frame is a profile + steel plate welding structure, hydraulic shearing, hydraulic pressing, and pressing platform |

| 4 | Servo Feeding | 1. Maximum feeding speed: 15m/min 2. The maximum allowable feeding width: ≤1700mm 3. Allowable feeding thickness: ≤8mm 4. Single feeding error: ≤±1mm (the tolerance is not cumulative) 5. Servo motor power: ≈15Kw (subject to the final design) 6. The material of the feeding roller is: 9Cr2Mo (or GCr15), hardness HRC55-60 |

| Punching Press | Adopt liquid four-column press mode Punching Press: 500T Hole Size:15-φ25 |

|

| 5 | Roll Forming Machine | Structure: the forming unit is driven by motor reducer chain Forming stations: 24 stations Forming machine shaft dia: φ180mm Motor power: 180kw Max.: 2-8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing Blade material: Cr12MoV (hardness after quenching HRC58~62) Parameter: cutting accuracy:±1.5mm |

| 7 | Electrical Control Cabinet | Main electrical components: PLC: Mitsubishi Inverter: delta Touch screen: veron (Taiwan, China) Low-voltage electrical appliances: schneider (France) Encoder: Omron (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

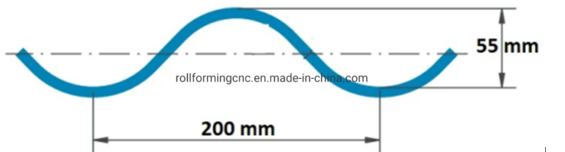

WORKPIECE SAMPLES

The culvert corrugated plate is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

APPLICATION

The culvert corrugated board production line is a special equipment for culvert corrugated board compression molding, which is widely used in construction industry and other facilities, including railway bridge tunnels, highway bridge tunnels etc.

Product detail pictures:

Related Product Guide:

Our target is always to satisfy our customers by offering golden support, superior value and high quality for Factory made hot-sale Shelf Roll Forming Machine - Culvert Corrugated Plate Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Cannes, Honduras, Tunisia, Our experience makes us important in our customer eyes. Our quality speaks itself the properties like it do not tangle, shed or breakdown, so that are our customers will always be confident while placing an order.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

Write your message here and send it to us