Factory Outlets Guide Rail Roll Forming Machine - The Solar PV Strut Bracket Roll Forming Production Line – Raintech

Factory Outlets Guide Rail Roll Forming Machine - The Solar PV Strut Bracket Roll Forming Production Line – Raintech Detail:

MAIN TECHNICAL PARAMETERS

The Solar PV Strut Roll Forming Machine

This solar photovoltaic bracket is the production of solar photovoltaic brackets. The solar photovoltaic bracket is a special bracket designed for placing, installing and fixing solar panels in the solar photovoltaic power generation system.

The Function:

This roll forming line specially do the process of punching holes, forming rolling of the solar strut bracket , PV stand rack .

Main process of the whole line :

uncoiler——guiding feeding ——forming ——cut to length ——finished product

Raw material specification

| Material | hot rolled low carbon steel |

| Yield strength | 235Mpa |

| Coils OD | ≤Ф1200 mm

|

| Coils ID | Ф508mm |

| Strips width | ≤250mm |

| Steel thickness | 1.5~2.5mm |

| Coil weight | ≤2500 kg |

| Overall layout size | 25000X3000X1800 |

| Archway stands material | QT450 |

| Rollers shaft material | 40Cr,quenching,hardness HRC45~50 |

| Archway stand forming sets | 20 sets |

| Forming shaft dia | φ70mm |

| Motor | approx.. 30KW |

| Max. line speed | 5~15m/min |

MAIN COMPONENTS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support

Coils ID:Ф508mm Coil OD :Ф1200mm Coil Width :500mm coil weight:≤5000 kg |

| 2 | Leveling Machine | 5 roller leveling

Max. speed:20m/min., Max. Leveling width:500mm, Max. Coil thickness:1~3mm Power of leveling machine: approx. 7.5kw (subject to final design) |

| 3 | Servo Feeder | Maximum feeding speed:30m/min

Maximum feed width :≤500mm Allowed feed thickness≤3mm Precision of feeding:±0.2mm/step Servo motor:Japan, Yaskawa Servo Motor Power:aprox.4.4KW(according to final design) |

| 4 | Multi-Punching | To complete the punching holes on the profile. |

| 5 | Quick Change Roll Forming Machine |

There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft). Archway material: QT450. 8/13 Quotation documents Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50 Parameters: Forming passes: 36 passes (subject to the final design) Archway sorties: 36+32=68 sorties Shaft diameter of forming machine: φ70mm (subject to final design) Motor power: 55kw Maximum linear speed: 2~8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing

Blade material :Cr12MoV (hardness after quenching HRC58~62) Parameter :cutting accuracy:±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi

Inverter: Delta Touch screen: Vinylon (Taiwan, China) Low-voltage electrical appliances: Schneider (France) Encoder: Omron (Japan) Servo controller: Yaskawa (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

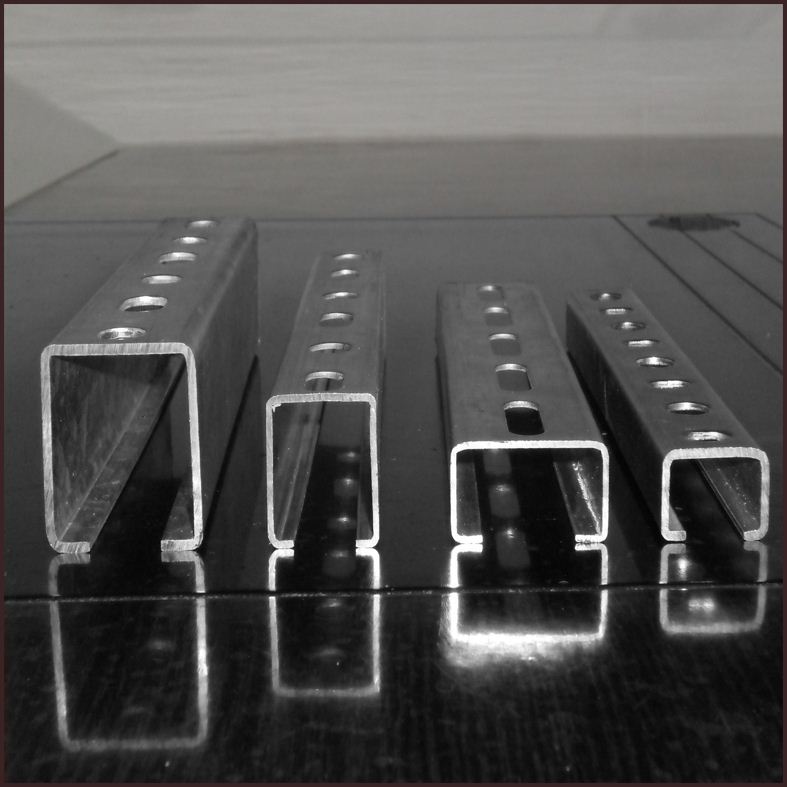

WORKPIECE SAMPLES

Product detail pictures:

Related Product Guide:

Responsible excellent and fantastic credit rating standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, buyer supreme" for Factory Outlets Guide Rail Roll Forming Machine - The Solar PV Strut Bracket Roll Forming Production Line – Raintech , The product will supply to all over the world, such as: Rome, Moscow, Costa Rica, They're durable modeling and promoting well all over the world. Under no circumstances disappearing key functions in a brief time, it's a should for you personally of fantastic quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the business make an awesome efforts to expand its international trade, raise its enterprise. rofit and improve its export scale. We are confident that we'll have a vibrant prospect and to be distributed all over the world in the years to come.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.