Factory Price For Rolling Shutter Strip Making Machine - Cable Tray Roll Forming Machine – Raintech

Factory Price For Rolling Shutter Strip Making Machine - Cable Tray Roll Forming Machine – Raintech Detail:

PRODUCTION DESCRIPTIONA

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc.

MAIN TECHNICAL PARAMETERS

| No | Model: SART-1250*2.5 | Specification |

| 1 | Material | CR/HR/G. I steel |

| 2 | Coil OD | Ф1200 mm |

| 3 | Coil ID | Ф508mm |

| 4 | Strips width | <1250mm |

| 5 | Strips Thickness | 0.5~2.5mm |

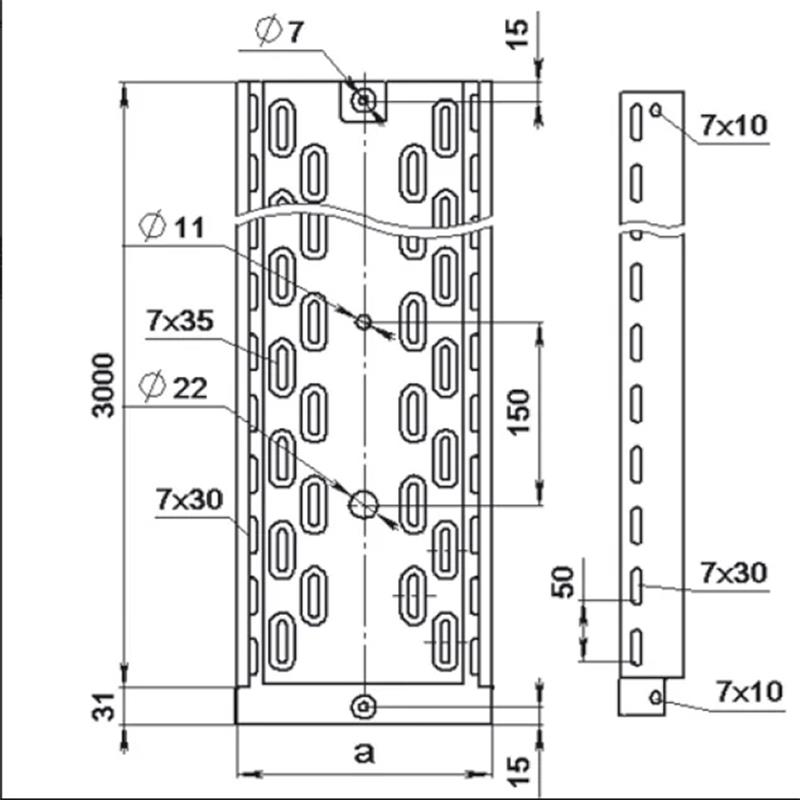

| 6 | Cable Tray Width | 100~800mm |

| 7 | Cable Tray Height | 50~200mm |

| 8 | Coils weight | ≤10000 kg |

| 9 | Electrical power | 415V,50Hz,3phase |

| 10 | Line Speed | 5~15m/min |

MAIN COMPONENTS

This production line is mainly composed by following parts:

1. Uncoiler. 1 set

Single support,four-bar tension structure, tension force comes from hydraulic cylinder, adjustment is fast and reliable.

2. Leveler. 1 set

It adopts 7 rollers for leveling, 2 pairs of guide rollers, feed rollers are pneumatically clamped, frequency conversion speed regulation, switch control.

3. Looper ( Storage Material) 1 set

Used to buffer the speed mismatch between the unwinding and leveling and the punching machine, and correct the deviation;

4. Servo Feeder. 1 set

The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick.

5. Multi-stations Punching&Cutting Unit 1 set

It adopts liquid four-column press mode, which is economical, applicable and fast. The punching machine has a 6-station punching mode and contains 3 to 4 sets of die sets, which can continuously punch out multiple types of holes.

6. Cantilever adjustable forming machine 1 set

The forming unit adopts the cantilever forming machine mode. Motor, reducer, spiral bevel gear drive.When producing products with different bottom widths and waist heights, you only need to set the parameters on the touch screen, which is convenient, fast and reliable.

PRODUCTION PROCESS

Uncoiler → Leveler → Loop (storage) → Sevo Motor → multi-stations punching machine(cutting)→ Finished Products

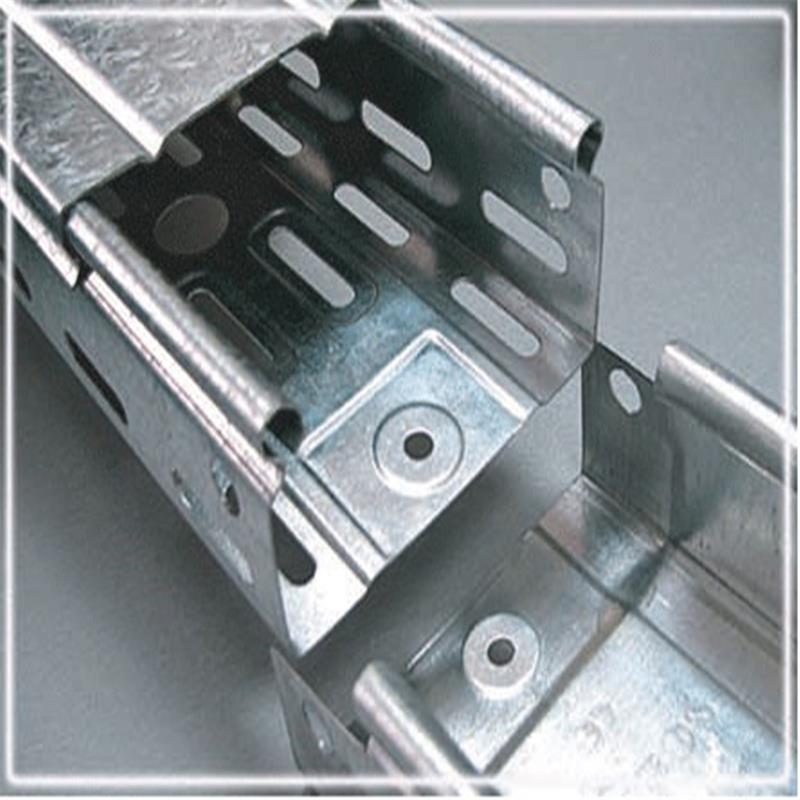

WORKPIECE SAMPLES

Cable tray roll forming machine / cable bridge making machine / electrical cable tray forming production line / cable cover making machine / cable tray making machine / able bridge roll forming production line.

Product detail pictures:

Related Product Guide:

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of Factory Price For Rolling Shutter Strip Making Machine - Cable Tray Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Canada, Ghana, Barbados, We always stick to the tenet of "sincerity, high quality, high efficiency, innovation". With years of efforts, we have established friendly and stable business relationships with worldwide customers. We welcome any of your inquiries and concerns for our products, and we are sure that we will offer just what you want, as we always believe that your satisfaction is our success.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!