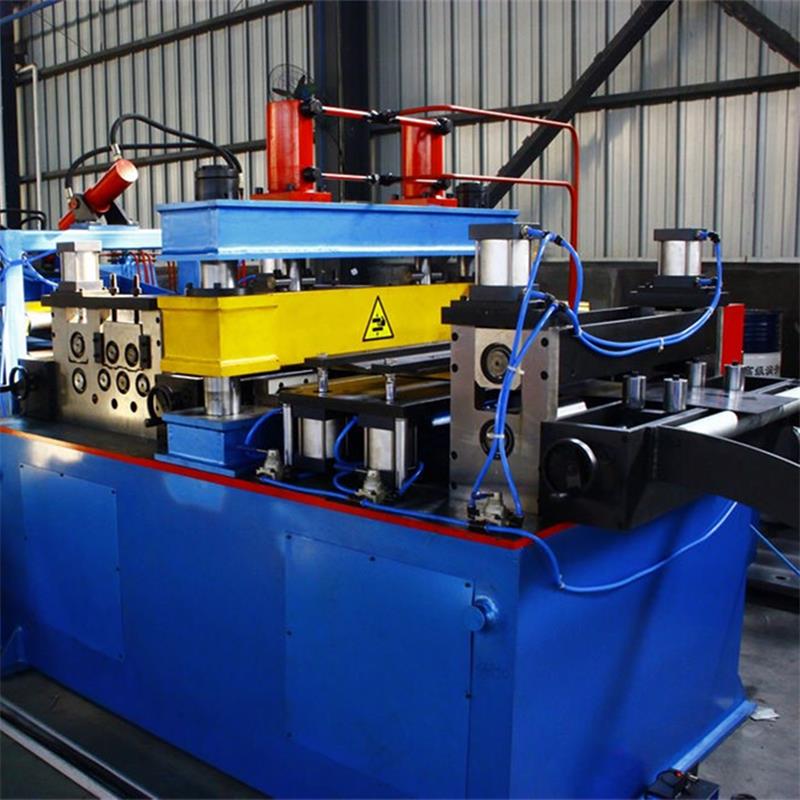

Fixed Competitive Price Corrugated Sheet Rolling Machine - Storage Shelf Rack Roll Forming Machine – Raintech

Fixed Competitive Price Corrugated Sheet Rolling Machine - Storage Shelf Rack Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

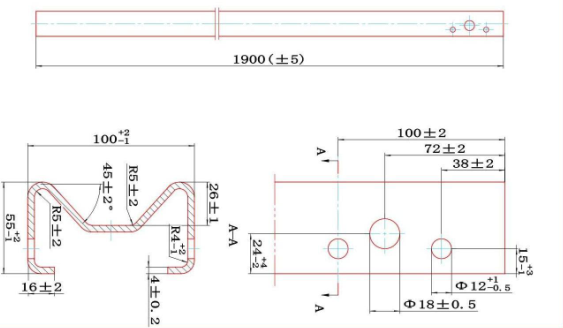

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for Fixed Competitive Price Corrugated Sheet Rolling Machine - Storage Shelf Rack Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Australia, Cannes, Riyadh, Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!