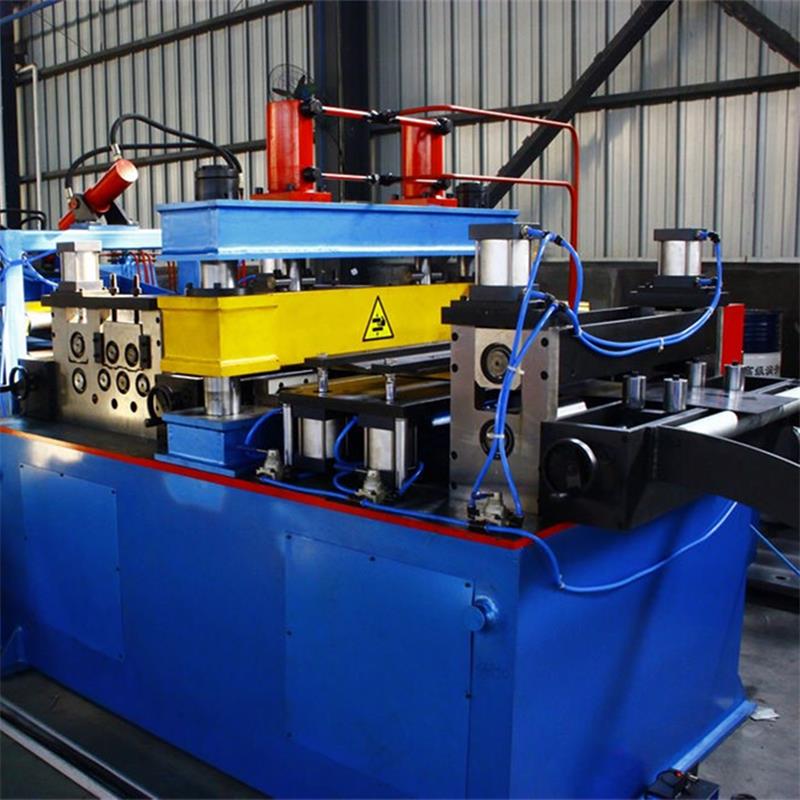

Good Quality Floor Deck Forming Machine - Storage Shelf Rack Roll Forming Machine – Raintech

Good Quality Floor Deck Forming Machine - Storage Shelf Rack Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

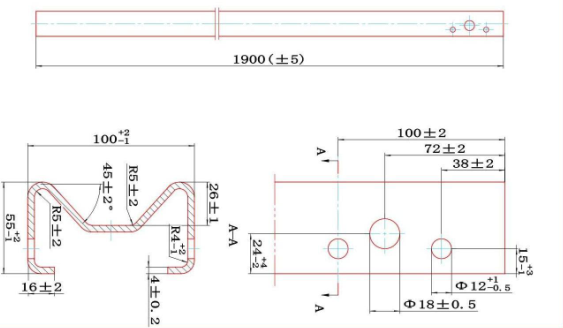

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Product detail pictures:

Related Product Guide:

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for Good Quality Floor Deck Forming Machine - Storage Shelf Rack Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Cologne, Mozambique, Chicago, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products and solutions for our customers.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.