Good Wholesale Vendors Rolling Shutter Machine - Hat Channel Profile Roll Forming Machine – Raintech

Good Wholesale Vendors Rolling Shutter Machine - Hat Channel Profile Roll Forming Machine – Raintech Detail:

PRODUCT DESCRIPTION

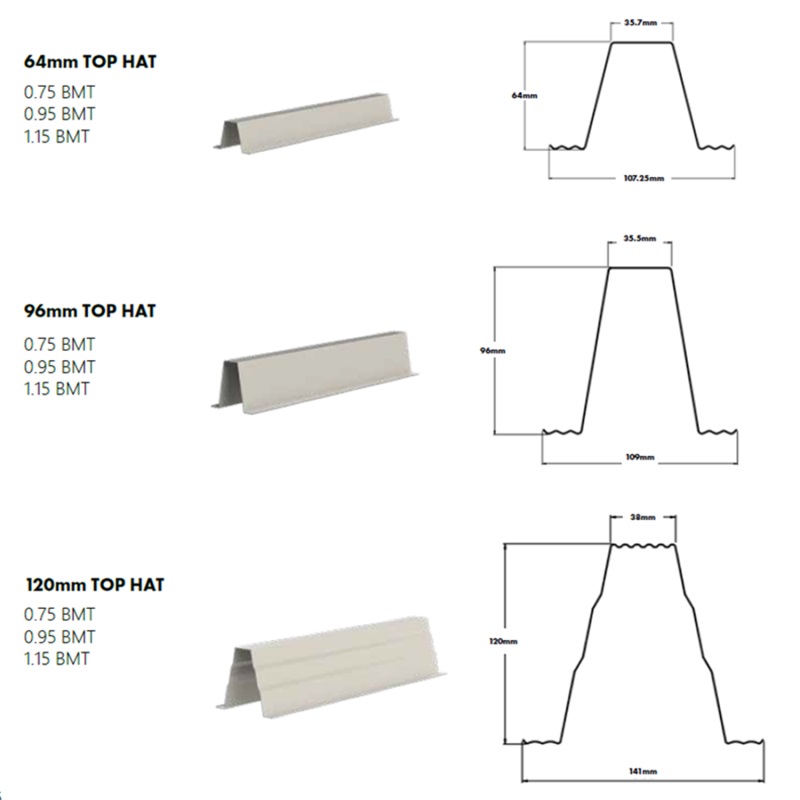

Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive.

Our hat profile roll forming machine is for making the hat channels, which widely applicable in metal/steel roof construction industries.

MAIN TECHNICAL PARAMETERS

| 1 | Machine structure | Individual archway stands structure |

| 2 | Total power | Motor power-18.5kw Hydraulic power-5.5kw |

| 3 | Roller stations | 18 dots stations |

| 4 | Productivity | 15-25m/min |

| 5 | Decoiler | 3T hydraulic decoiler |

| 6 | Leverling part | Upper is 3 rollers, down is 4 stations(total is 7 rollers) |

| 7 | Drive system | By independent gearbox |

| 8 | Diameter of shaft | ¢60mm solid shaft |

| 9 | Roller material | American D2 D3 |

| 10 | Pre punching& cutting system | Pre-cutting to change the material Material of the punching mold: Cr12 |

| 11 | Hydraulic cutting system | Cr12 with heat treatment 58-60° |

| 12 | Hydraulic power | 7.5KW |

MAIN COMPOSITIONS

|

1 |

Automatic De-coiler | 1. Single head design 2. Loading weight: 3Tons 3. Hydraulic automatic expansion and tightening 4. Suitable width: <300mm 5. Coil ID: ¢500±20mm 6. Coil OD: ≤1200mm |

|

2 |

Servo Feeding Leveling | 1. It adopts 5 rollers for leveling, 2 pairs of guide rollers 2. Maximum leveling roll width: 300mm 3. Adapt to the maximum roll thickness: 1~2mm 4. Maximum working speed: 20 m/min 5. Driven: servo motor |

|

3 |

Multi-functional Punching Machine | 1. 6 punching stations, 2. Servo motor power: 1.3KW 3. Servo motor brand: Japan Yaskawa 4. Suitable width: <300mm 5. Punching mold fast positioning, repeat positioning. |

|

4 |

Roll Forming Machine | 1. Driven system: Motor, reducer, spiral bevel gear drive 2. Main machine power: 15KW*2 Sets, 3. Motor brand: SIEMENS BADE servo motor 4. Module Components fast positioning, repeat positioning 5. Forming stations: 18 groups stations |

|

5 |

Hydraulic Cutting Machine | 1. Hydraulic single station, 2. Cutting force: 30Tons, 3. Cutting type: stop cutting 4. Module Components fast positioning, repeat positioning |

|

6 |

Computer Control Box | 1. Japan Mitsubishi motion controller PLC 2. Japan Yaskawa Servo System 3. With human machine interface touch screen 4. Schneider weak current control |

|

7 |

Hydraulic Station | 1. Hydraulic system power: 15KW 2. Hydraulic value: Huade, 3. With fan cooling system |

PRODUCTION PROCESS

Uncoiling → leveling → Looper (storage) → servo feeding → Multi-stations punching → forming station → Hydraulic cutting → Finished product discharging

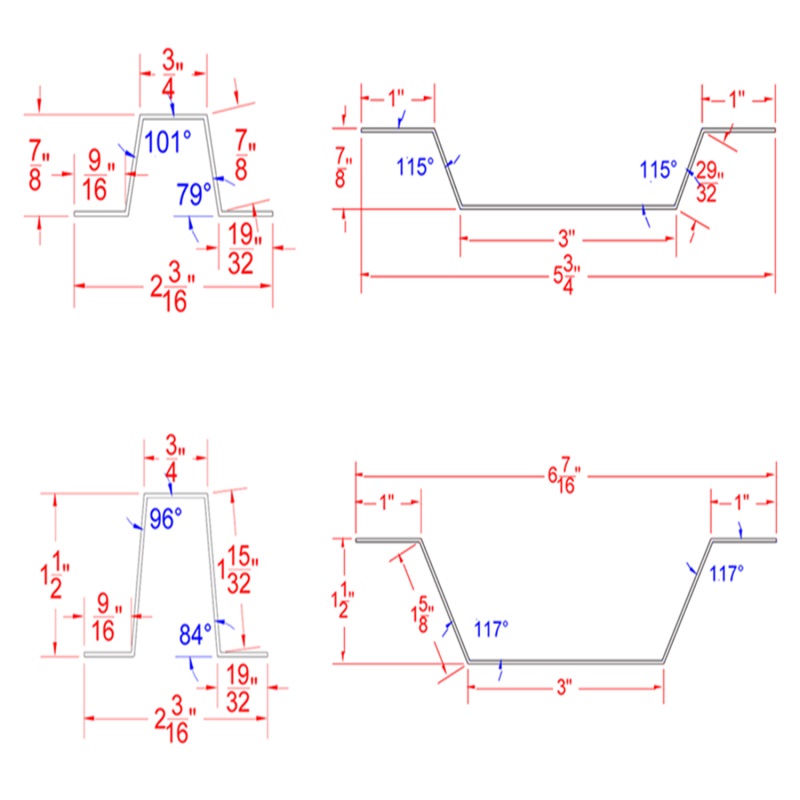

WORKPIECE SAMPLES

Hat channel roll forming machine;hat profile forming machine;hat profile channel making machine

Product detail pictures:

Related Product Guide:

Dedicated to strict high-quality management and considerate purchaser support, our experienced employees members are usually available to discuss your specifications and be certain full shopper satisfaction for Good Wholesale Vendors Rolling Shutter Machine - Hat Channel Profile Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Hanover, Swiss, San Diego, Our company abides by the management idea of "keep innovation, pursue excellence". On the basis of assuring the advantages of existing products, we continuously strengthen and extend product development. Our company insists on innovation to promote the sustainable development of enterprise, and make us become the domestic high-quality suppliers.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!

Write your message here and send it to us