High definition Metal Roof Tile Machine - High Quality CZU L Fast Change Roll Forming Machine – Raintech

High definition Metal Roof Tile Machine - High Quality CZU L Fast Change Roll Forming Machine – Raintech Detail:

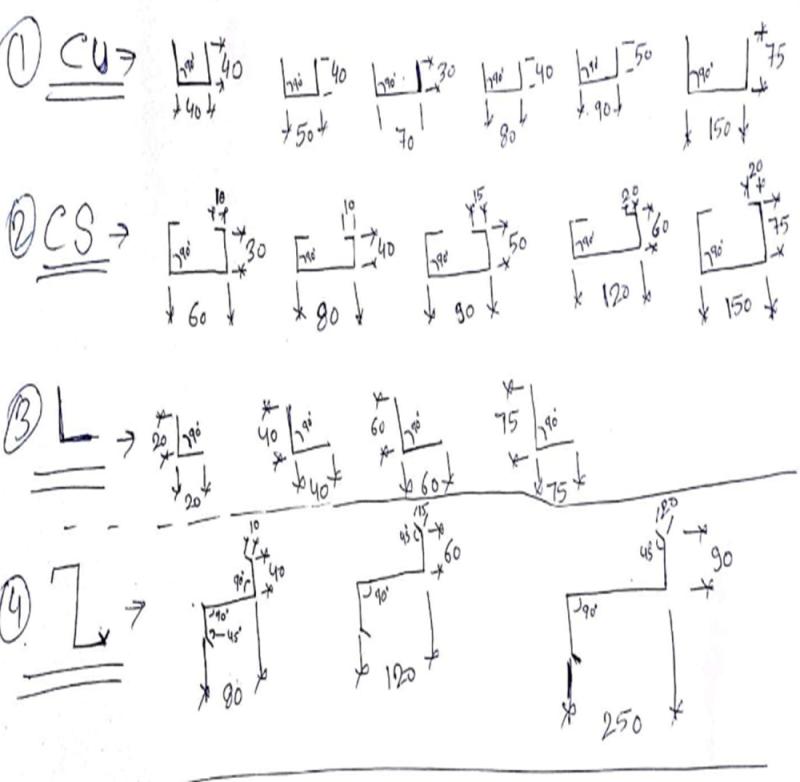

MAIN TECHNICAL PARAMETERS

|

Profile |

Web |

Flange |

Lip |

Thickness |

|

C |

80-300mm |

40-80mm |

10-25mm |

1.2-3.2mm |

|

Z |

120-300mm |

40-80mm |

10-25mm |

1.2-3.2mm |

Fast Changing Structure

PRODUCTION PROCESS

Uncoiling → Leveling → Looper (Material Storage) → Servo Feeding → Multi-Station Punching Machine (Cutting Off) → Roll Forming Machine → Finished Products

MAIN COMPONENTS

This production line is mainly composed by following parts:

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coils ID: Ф508mm; Coil OD : Ф1200mm; Coil Width : 500mm; Coil weight: ≤5000 kg; |

| 2 | Leveling Machine | 5 roller leveling; Max. speed: 20m/min; Max. Leveling width: 500mm; Max. Coil thickness: 1~3mm; Power of leveling machine: approx. 7.5kw (subject to final design) |

| 3 | Servo Feeder | Maximum feeding speed: 30m/min; Maximum feed width: ≤500mm; Allowed feed thickness: ≤3mm; Precision of feeding: ±0.2mm/step; Servo motor: Japan, Yaskawa; Servo Motor Power: aprox.4.4KW (according to final design) |

| 4 | Multi-Punching | To complete the punching holes on the profile. |

| 5 | Quick Change Roll Forming Machine | There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft). Archway material: QT450. 8/13Quotation documents; Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50; Parameters: Forming passes: 36 passes (subject to the final design); Archway sorties: 36+32=68 sorties; Shaft diameter of forming machine: φ70mm (subject to final design); Motor power: 55kw; Maximum linear speed: 2~8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade materialBlade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy: ±1.5mmAccuracy: ±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi; Inverter: Delta; Touch screen: Vinylon (Taiwan, China); Low-voltage electrical appliances: Schneider (France); Encoder: Omron (Japan); Servo controller: Yaskawa (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

WORKPIECE SAMPLES OF TILE MAKING MACHINE

CZ quick change roll forming machine line; CZUL fast change roll forming machine; c purlin fast change roll forming machine; CZ Purlin Roll Forming Machine

Product detail pictures:

Related Product Guide:

We believe that prolonged expression partnership is really a result of top of the range, value added support, rich encounter and personal contact for High definition Metal Roof Tile Machine - High Quality CZU L Fast Change Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Latvia, Haiti, Denmark, Our company has a skillful sales team, strong economic foundation, great technical force, advanced equipment, complete testing means, and excellent after-sales services. Our items have beautiful appearance, fine workmanship and superior quality and win the unanimous approvals of the customers all over the world.

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

Write your message here and send it to us