Hot Sale for Shutter Spring Machine - Highway Guardrail C Post Profile Roll Forming Machine – Raintech

Hot Sale for Shutter Spring Machine - Highway Guardrail C Post Profile Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

Material: Galvanized Sheet

Yield strength of raw materials: 235Mpa

Coil Outer Diameter: ≤Ф1200 mm

Coil Inner Diameter: Ф508mm

Steel Strip Width: ≤150mm

Steel Strip Thickness: 2mm

Coil Weight: ≤2000 kg

Machine Floor Area: 25000X3000X1800

PRODUCTION PROCESS

The production line is carried out according to the following process::

Uncoiling→Leveling Servo Feeding→Punching→Cold Roll Forming→Hydraulic Shearing→Material Discharging

MAIN COMPONENTS

1. Uncoiler 1set

Allowable coil inner diameter: Ф508

Max. allowable coil outer diameter: Ф1200mm

Max. allowable roll width: 200 mm

Max. roll carrying weight: ≤2000 kg

2. Servo Feeding 1 set

Maximum feeding speed: 30m/min

Maximum allowable feeding width: ≤200mm

Allowed feeding thickness ≤ 2mm

Single feeding error: ≤±0.2mm (the tolerance is not cumulative)

Servo motor brand: Yaskawa (YASKAWA, Japanese)

Servo motor power: ≈3Kw (subject to the final design)

3. Punching Machine 1set

It adopts liquid four-column press mode, which is economical, applicable and fast. The punching distance is adjustable in the transverse direction of the plate, and the punching step can be changed through the electrical control system.

4. Roller Forming Machine 1 set

Archway material: QT450.

Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50

Forming pass: 12 passes

Shaft diameter of forming machine: φ60mm (subject to final design)

Motor power: about 30kW (subject to the final design)

Maximum linear speed: 3~10m/min

5. Pneumatic follow-up shearing 1 set

Cutter material: Cr12MoV (hardness after quenching is HRC58~62)

6. Hydraulic System 1 set

The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic oil tank, etc.The hydraulic system uses a filter, and the cleanliness of the oil is guaranteed to be level 6-8.

MAIN ELECTRICAL COMPONENTS

| No | Items Name | Brand |

| 1 | PLC | Mitsubishi, Japan |

| 2 | Servo Motor | Yaskawa, Japan |

| 3 | Inverter | Delta (Taiwan, China) |

| 4 | Touch screen | Vinylon (Taiwan, China) |

| 5 | Low-voltage electrical components | Omron |

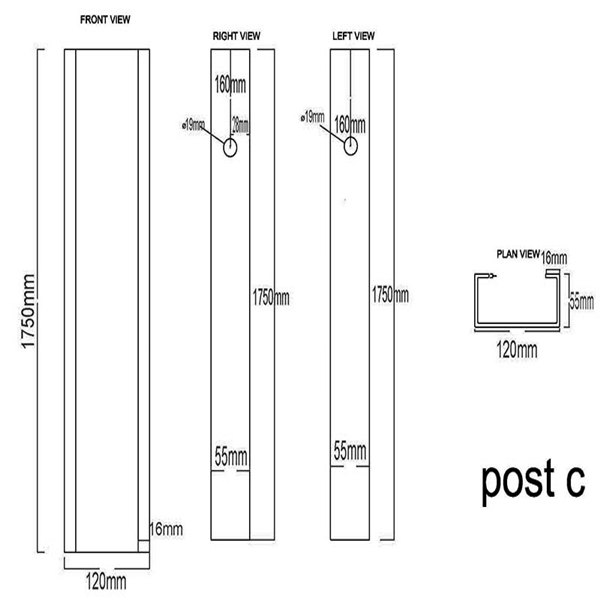

WORKPIECE SAMPLES

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Hot Sale for Shutter Spring Machine - Highway Guardrail C Post Profile Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Islamabad, Congo, French, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!