Leading Manufacturer for Corrugated Sheet Machine Price - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech

Leading Manufacturer for Corrugated Sheet Machine Price - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Material | Cold rolled low carbon steel |

| Yield strength of raw materials | 235Mpa |

| Tensile strength of raw materials | ≤550Mpa |

| Coil outer diameter | ≤Ф1600 mm |

| Inner diameter of coil | Ф508mm |

| Strip thickness | 2.3~3mm |

| Single roll weight | ≤7000 kg |

PRODUCTION PROCESS

The Production Line Is Carried Out According To The Following Process:

Uncoiler → Looper (Storage) → Servo Feeding → Punching Machine → Roller Forming → Shearing → Automatic Palletizing Of Finished Products

MAIN COMPONENTS

1. Uncoiler

The machine is a single-head mode. With single support, the motor drives the material shaft of the uncoiler to release the material roll, and the hydraulic power drives the tension device of the material shaft of the uncoiler to fix the material roll on the material shaft of the uncoiler.

2. Material Storage Device

The storage device is composed of two parts: the arc-shaped roller and the supporting device. There are four groups of arc-shaped rollers. Between the two storage bins, they are composed of an arc frame and a single rotating roller. A photoelectric switch is installed in the pit of the silo to control the position of the roll entering the pit, so that the speed of each working part can be perfectly matched.

3. Leveling Servo Feeder

The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick. The feeding accuracy is accurate without accumulated tolerance.

4. Pneumatic follow-up shearing

It cuts the formed parts to a fixed length. The whole working process does not need to stop the whole line, and it automatically tracks and cuts, which is fast and efficient

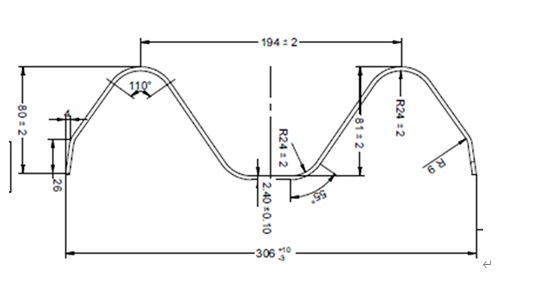

WORKPIECE SAMPLES

APPLICATION

Guardrails are widely used in industry, agriculture, municipal administration, transportation and other industries for decoration, maintenance and protection

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Leading Manufacturer for Corrugated Sheet Machine Price - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Russia, Iceland, Poland, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.