Low price for Purlin Forming Machine - PU Sandwich Panel Roll Forming Machine – Raintech

Low price for Purlin Forming Machine - PU Sandwich Panel Roll Forming Machine – Raintech Detail:

PRODUCT DESCRIPTION

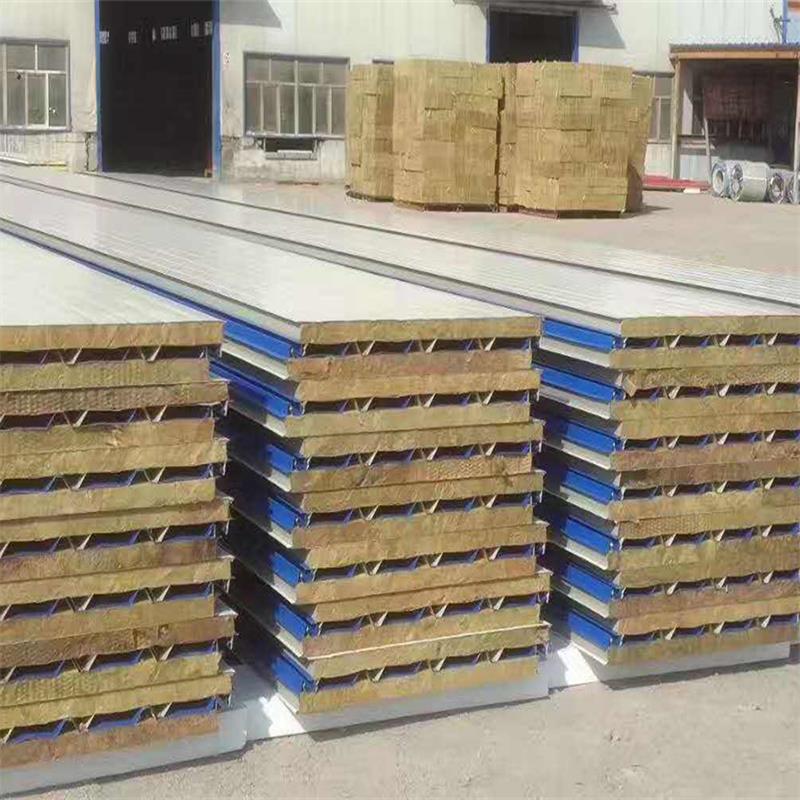

Rock wool foam sandwich panel dual-use composite machine equipment is made of high quality color steel plate and light inner core material, through the special composite production line made of one or two sides of the outer layer, forming a high strength, light weight, good heat insulation effect of a new type of construction and decoration materials.

Because of its strong and durable, beautiful appearance and convenient construction, low cost is welcomed by all walks of life, is widely used in industrial plants, large warehouses, large span roof, walls, simple rooms, kiosks, cold storage, purification room, air conditioning room and other places.

MAIN TECHNICAL PARAMETERS

1. Feed width: 1000mm/1200mm

2. Material thickness: 50-200mm for rock wool, 50-250mm for foam

Two, main technical parameters:

1. Overall size: 45000*2200*2800

2. Motor power: 32KW

3. Production line speed: 6-8m/min

4. machine weight: 12-14T

5. pressing thickness: single tile machine 0.3-0.8mm composite machine 50-200mm

6. Advantages of the machine: the surface is smooth and without abrasion, and the bonding is firm.

7. power supply: AC380V/ 50-60Hz

PRODUCTION PROCESS

The polyurethane sandwich panel continuous production line integrates functions such as uncoiling, cutting butt jointing, laminating, beading/forming, preheating, foaming, continuous curing, cutting, stacking, packaging, etc., with high degree of automation and stable performance.

MAIN COMPONENTS

This machine mainly composed of feeding rack, tile press, composite host, cutting part, dragging rack.

1. Discharging rack: it is composed of bracket and discharging coil core, bearing 5-7 tons

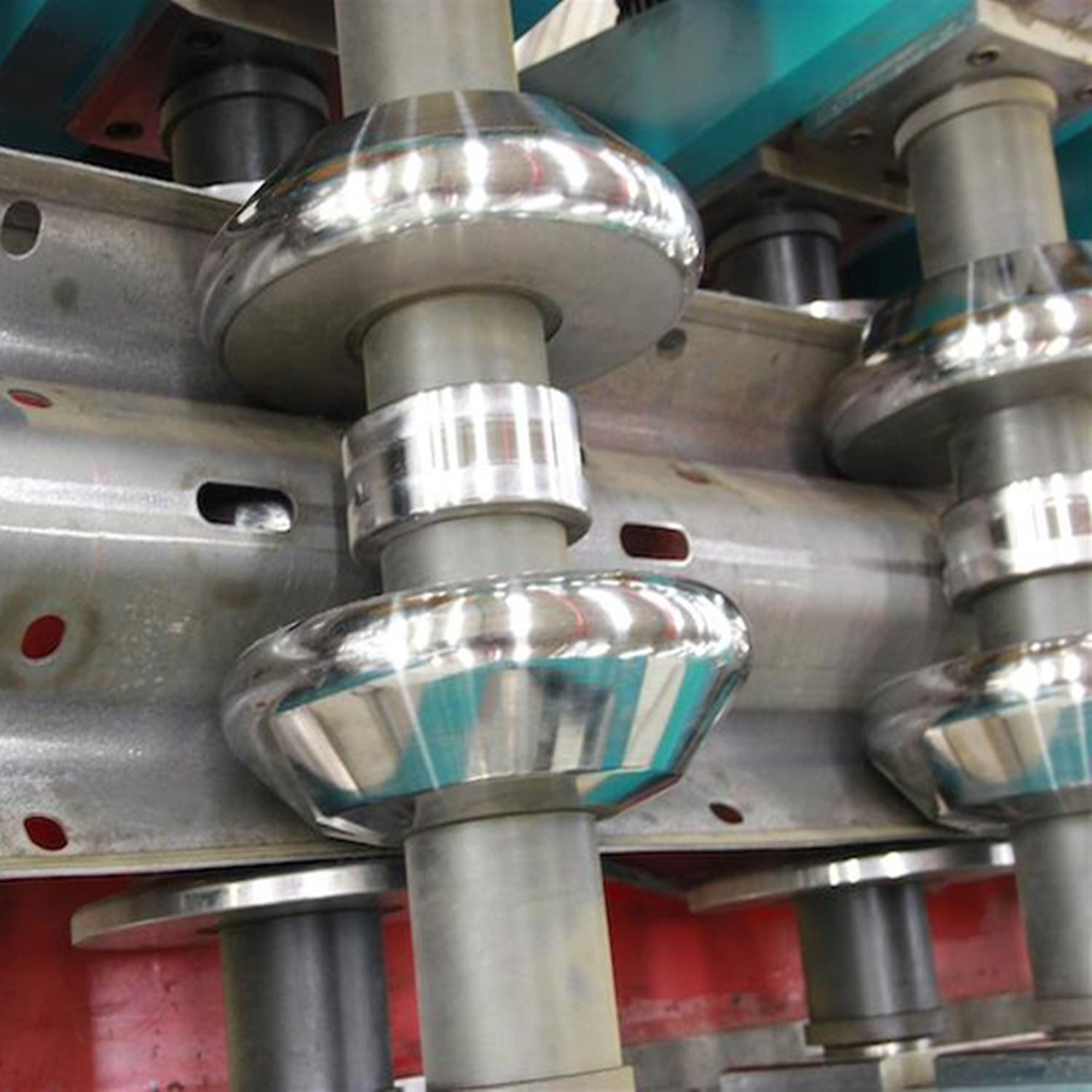

2. Tile press: forming 13 row axis, axis: 70 plate: 12mm frame: 250H steel chain: 6 points

3. Compound host: square tube: 80*160 rubber shaft: 150 19 corrugated shaft: 6 adjustable total 25

4. Cutting part: pneumatic walking

5. With three sets of loading rack

WORKPIECE SAMPLES

Pu sandwich panel production line; sandwich panel roll forming machine; eps sandwich panel roll forming machine.

ADVANTAGES

1. Beautiful shape optimization, low noise, high production efficiency.

2. It can not only produce single layer pressure plate, but also produce ordinary I-shaped aluminum composite plate and tongue-and-groove insert composite plate.

3. The host adopts advanced frequency conversion speed regulation, automatic fixed length cutting.

Product detail pictures:

Related Product Guide:

It adheres on the tenet "Honest, industrious, enterprising, innovative" to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for Low price for Purlin Forming Machine - PU Sandwich Panel Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Palestine, Thailand, Anguilla, Our well-equipped facilities and excellent quality control throughout all stages of production enable us to guarantee total customer satisfaction. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact me. We are looking forward to forming successful business relationship with new clients around the world.

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!