Manufactur standard Shutter Door Forming Machine - The Solar PV Strut Bracket Roll Forming Production Line – Raintech

Manufactur standard Shutter Door Forming Machine - The Solar PV Strut Bracket Roll Forming Production Line – Raintech Detail:

MAIN TECHNICAL PARAMETERS

The Solar PV Strut Roll Forming Machine

This solar photovoltaic bracket is the production of solar photovoltaic brackets. The solar photovoltaic bracket is a special bracket designed for placing, installing and fixing solar panels in the solar photovoltaic power generation system.

The Function:

This roll forming line specially do the process of punching holes, forming rolling of the solar strut bracket , PV stand rack .

Main process of the whole line :

uncoiler——guiding feeding ——forming ——cut to length ——finished product

Raw material specification

| Material | hot rolled low carbon steel |

| Yield strength | 235Mpa |

| Coils OD | ≤Ф1200 mm

|

| Coils ID | Ф508mm |

| Strips width | ≤250mm |

| Steel thickness | 1.5~2.5mm |

| Coil weight | ≤2500 kg |

| Overall layout size | 25000X3000X1800 |

| Archway stands material | QT450 |

| Rollers shaft material | 40Cr,quenching,hardness HRC45~50 |

| Archway stand forming sets | 20 sets |

| Forming shaft dia | φ70mm |

| Motor | approx.. 30KW |

| Max. line speed | 5~15m/min |

MAIN COMPONENTS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support

Coils ID:Ф508mm Coil OD :Ф1200mm Coil Width :500mm coil weight:≤5000 kg |

| 2 | Leveling Machine | 5 roller leveling

Max. speed:20m/min., Max. Leveling width:500mm, Max. Coil thickness:1~3mm Power of leveling machine: approx. 7.5kw (subject to final design) |

| 3 | Servo Feeder | Maximum feeding speed:30m/min

Maximum feed width :≤500mm Allowed feed thickness≤3mm Precision of feeding:±0.2mm/step Servo motor:Japan, Yaskawa Servo Motor Power:aprox.4.4KW(according to final design) |

| 4 | Multi-Punching | To complete the punching holes on the profile. |

| 5 | Quick Change Roll Forming Machine |

There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft). Archway material: QT450. 8/13 Quotation documents Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50 Parameters: Forming passes: 36 passes (subject to the final design) Archway sorties: 36+32=68 sorties Shaft diameter of forming machine: φ70mm (subject to final design) Motor power: 55kw Maximum linear speed: 2~8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing

Blade material :Cr12MoV (hardness after quenching HRC58~62) Parameter :cutting accuracy:±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi

Inverter: Delta Touch screen: Vinylon (Taiwan, China) Low-voltage electrical appliances: Schneider (France) Encoder: Omron (Japan) Servo controller: Yaskawa (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

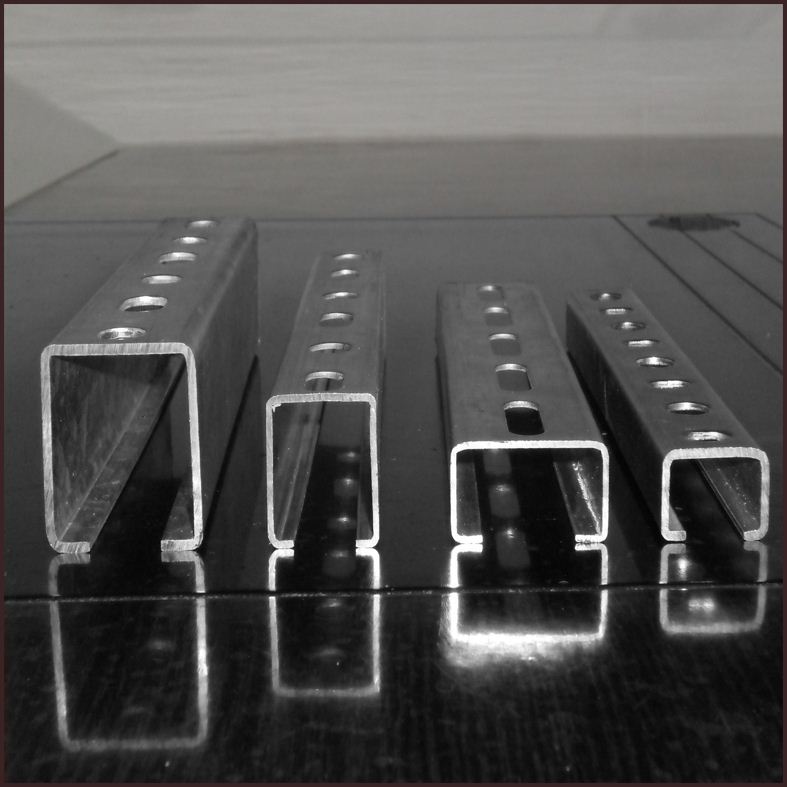

WORKPIECE SAMPLES

Product detail pictures:

Related Product Guide:

Our growth depends to the superior products ,great talents and repeatedly strengthened technology forces for Manufactur standard Shutter Door Forming Machine - The Solar PV Strut Bracket Roll Forming Production Line – Raintech , The product will supply to all over the world, such as: Turkey, Japan, El Salvador, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.