Manufacturer for Steel Coil Slitter - Metal coils cut to length line slitting line – Raintech

Manufacturer for Steel Coil Slitter - Metal coils cut to length line slitting line – Raintech Detail:

<iframe width=”560″ height=”315″ src=”https://www.youtube.com/embed/bqocZZDy6w0″ title=”YouTube video player” frameborder=”0″ allow=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture” allowfullscreen></iframe>

Production Description

The slitting line is also called slitting unit, slitting machine, slitting machine, and scissors. It cuts the metal coils into strips of various required widths, and then collects the strips into small rolls for the next process. It is a necessary equipment for precision cutting of transformers, motor industries and other metal strips. Raintech steel coil slitting line is designed according to our customers special requirements. This line is for the metal coils thickness 0.5-3mm thickness, width of coil less than 1300mm. Line speed can up to 200m/min. The production line compose of the process of uncoiler- servo feeding leveler-end shear-slitter-recoiler .

Advantages:

1. High cutting quality

2. High utilization rate of materials

3. Stepless cutting speed regulation

Uncoiling Unit

1. Several coils can be pre-placed on the loading station to improve working efficiency.

2. This uncoiling unit of our slitting line adopts a hydraulic collapsible drum, which does no harm to the sublayer of the material. It is capable of carrying out tensile uncoiling or manual material unloading, which effectively prevents the material from deflecting and scraping.

3. Both single-head and double-head type uncoiling units are available.

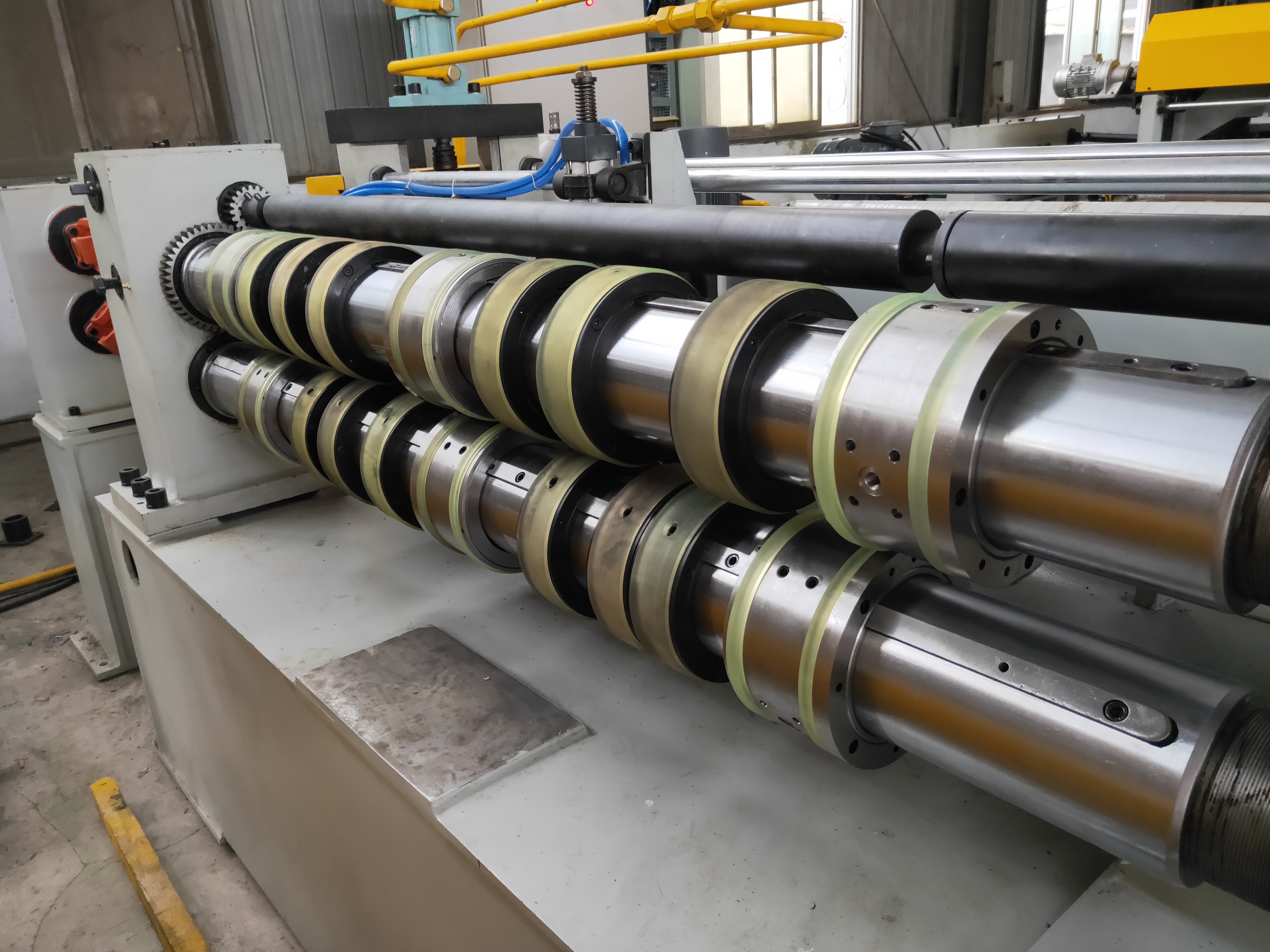

Slitting Unit

1. The slitting head arbors are fixed in eccentric sleeves. The slitting angle remains unchanged if the blade has just been polished.

2. This slitting line has two slitter heads. While one is running on line, kives setting up can be done on the other, which can greatly eliminate production down-time. As a result, this slitting line carries out slitting and blade changing simultaneously. This greatly increases the working efficiency.

3. Hydraulic locknuts could be used for higher blade positioning precision.

Tension Unit

1. Two pre-separation devices are fitted to this tension unit. The disengaging shaft could be transversely removed for faster switching of separating plates.

2. It has a friction type tensile working table. The adjustable tensile could be offered by hydraulic power or pneumatic power.

3. Our slitting line could also be equipped with a roller type tightening machine, which is suitable for materials of coated surfaces because it does not harm the coated surfaces.

Coiler

1. Our slitting line could be fitted with a seamless hydraulic expansion coiler, which does not damage the sub-layer of the material.

2. The material clamping device has stress reducing characteristics. The roundness of the winding drum remains unchanged for plates of different thickness.

3. It carries out firm, dense and neat coiling.

Parameters of Slitting Line

| Model/ Items | Thickness (mm) | Width (mm) | Slitting Number |

| ESL-0.5×1000 | 0.15-0.5 | 300-1000 | 12 |

| ESL-0.5×1300 | 0.15-0.5 | 500-1300 | 24 |

| ESL-2X650 | 0.3-2 | 200-650 | 10-30 |

| ESL-2X1000 | 0.3-2 | 300-1000 | 10-30 |

| ESL-2×1300 | 0.3-2 | 500-1300 | 12-30 |

| ESL-2×1600 | 0.3-2 | 500-1600 | 12-30 |

| ESL-3×1600 | 0.3-3 | 500-1600 | 8-30 |

| ESL-3×1800 | 0.3-3 | 900-1800 | 8-30 |

| ESL-4×1600 | 1-4 | 900-1600 | 6-30 |

| ESL-6×1600 | 1-6 | 900-1600 | 6-30 |

| ESL-10×2000 | 2-10 | 900-2000 | 5-30 |

| ESL-12×2000 | 3-12 | 900-2000 | 5-30 |

| ESL-16×2000 | 3-16 | 900-2000 | 5-30 |

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for Manufacturer for Steel Coil Slitter - Metal coils cut to length line slitting line – Raintech , The product will supply to all over the world, such as: Angola, Malta, Cairo, Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers' satisfaction is our future!

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!