Massive Selection for Machine To Make Corrugated Metal Sheet - High Quality CZU L Fast Change Roll Forming Machine – Raintech

Massive Selection for Machine To Make Corrugated Metal Sheet - High Quality CZU L Fast Change Roll Forming Machine – Raintech Detail:

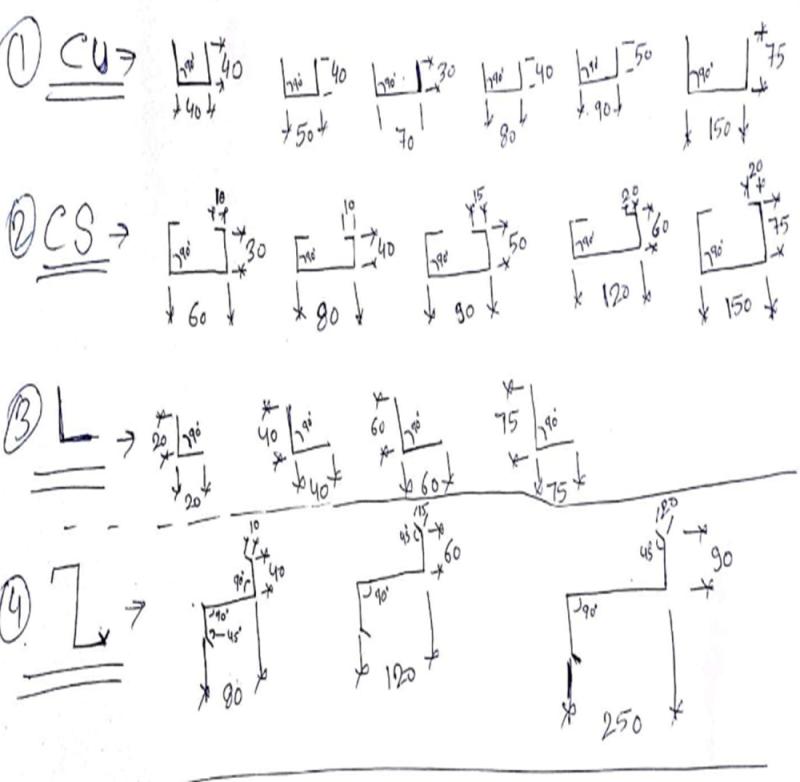

MAIN TECHNICAL PARAMETERS

|

Profile |

Web |

Flange |

Lip |

Thickness |

|

C |

80-300mm |

40-80mm |

10-25mm |

1.2-3.2mm |

|

Z |

120-300mm |

40-80mm |

10-25mm |

1.2-3.2mm |

Fast Changing Structure

PRODUCTION PROCESS

Uncoiling → Leveling → Looper (Material Storage) → Servo Feeding → Multi-Station Punching Machine (Cutting Off) → Roll Forming Machine → Finished Products

MAIN COMPONENTS

This production line is mainly composed by following parts:

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coils ID: Ф508mm; Coil OD : Ф1200mm; Coil Width : 500mm; Coil weight: ≤5000 kg; |

| 2 | Leveling Machine | 5 roller leveling; Max. speed: 20m/min; Max. Leveling width: 500mm; Max. Coil thickness: 1~3mm; Power of leveling machine: approx. 7.5kw (subject to final design) |

| 3 | Servo Feeder | Maximum feeding speed: 30m/min; Maximum feed width: ≤500mm; Allowed feed thickness: ≤3mm; Precision of feeding: ±0.2mm/step; Servo motor: Japan, Yaskawa; Servo Motor Power: aprox.4.4KW (according to final design) |

| 4 | Multi-Punching | To complete the punching holes on the profile. |

| 5 | Quick Change Roll Forming Machine | There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft). Archway material: QT450. 8/13Quotation documents; Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50; Parameters: Forming passes: 36 passes (subject to the final design); Archway sorties: 36+32=68 sorties; Shaft diameter of forming machine: φ70mm (subject to final design); Motor power: 55kw; Maximum linear speed: 2~8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade materialBlade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy: ±1.5mmAccuracy: ±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi; Inverter: Delta; Touch screen: Vinylon (Taiwan, China); Low-voltage electrical appliances: Schneider (France); Encoder: Omron (Japan); Servo controller: Yaskawa (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

WORKPIECE SAMPLES OF TILE MAKING MACHINE

CZ quick change roll forming machine line; CZUL fast change roll forming machine; c purlin fast change roll forming machine; CZ Purlin Roll Forming Machine

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Massive Selection for Machine To Make Corrugated Metal Sheet - High Quality CZU L Fast Change Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Qatar, Latvia, Belize, We will do our utmost to cooperate & satisfied with you relying on top-grade quality and competitive price and best after service ,sincerely look forward to cooperating with you and make achievements in the future!

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Write your message here and send it to us