Massive Selection for Sandwich Panel Machine - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech

Massive Selection for Sandwich Panel Machine - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Material | Cold rolled low carbon steel |

| Server system | YASKAWA |

| Steel belt width | ≤750mm |

| Production line speed | 15m/min |

| Electric control unit | PLC(Mitsubishi) |

MAIN COMPONENTS

1. Uncoiler

The machine is a single-head mode. With single support, the motor drives the material shaft of the uncoiler to release the material roll, and the hydraulic power drives the tension device of the material shaft of the uncoiler to fix the material roll on the material shaft of the uncoiler.

2. Uncoiler Parameter

| Allowable coil inner diameter | Ф508mm |

| Maximum allowable roll diameter | Ф1600mm |

| Maximum allowable roll width | 500 mm |

| Maximum roll carrying weight | ≤5000 kg |

| Uncoiler motor power | ≈5.5Kw (subject to the final design) |

3. Leveling Servo Feeder

The front of the leveling machine is also equipped with a telescopic shovel head and a material pressing device to ensure that the raw material rolls enter the leveling machine smoothly and safely.

| Maximum working speed | 40 m/min |

| Maximum leveling roll width | 500mm |

| Adapt to the maximum roll thickness | 2mm |

| Motor power of leveling machine: | ≈7.5Kw(subject to the final drawing design) |

4. Roller Forming Machine

The forming unit adopts an independent frame (housing mode). Motor, reducer drive, gear and chain drive.

| Forming Passes | about 13 |

| Shaft diameter of forming machine | φ80mm(subject to the final design) |

| Motor Power | about 55W(subject to the final design |

| Max. speed | 10~15m/min |

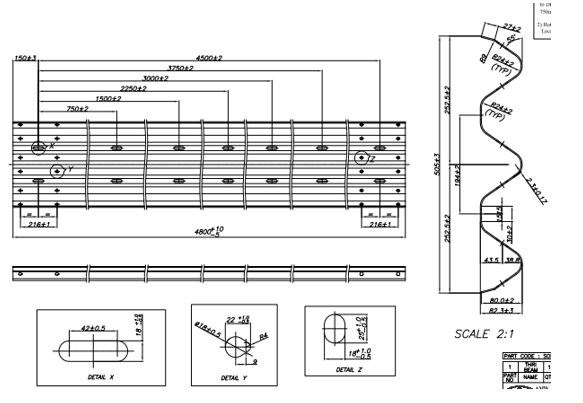

WORKPIECE SAMPLES

This is a 3 wave barrier made by our production equipment.

APPLICATION

Guardrails are widely used in industry, agriculture, municipal administration, transportation and other industries for decoration, maintenance and protection.

Product detail pictures:

Related Product Guide:

Our corporation insists all along the quality policy of "product top quality is base of organization survival; purchaser pleasure will be the staring point and ending of an company; persistent improvement is eternal pursuit of staff" plus the consistent purpose of "reputation very first, purchaser first" for Massive Selection for Sandwich Panel Machine - Waves Guardrail W Beam Plate Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Rotterdam, Czech republic, Brunei, Our company, is always regarding quality as company' s foundation, seeking for development via high degree of credibility , abiding by iso9000 quality management standard strictly , creating top-ranking company by spirit of progress-marking honesty and optimism.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.