OEM manufacturer Vehical Bumper Beam Roll Forming Machine - Combined Two and Three Beam Roll Forming Machine – Raintech

OEM manufacturer Vehical Bumper Beam Roll Forming Machine - Combined Two and Three Beam Roll Forming Machine – Raintech Detail:

Product Description

Raintech highway crash barrier roll forming machine have three types: Separated W beam roll forming machine, separated three waves crash barrier roll forming machine; combined two and three wave machine .

Working Process

Uncoiling → Servo leveling and feeding → 500T punching & cutting machine + punching and reinforced hole press → pinch feeder → transition material conveyor→ roll forming main process → Electromagnetic automatic palletizing device.

Parameter Technical

| Material: | Cold rolled mild steel |

| Raw material yield strength | 235Mpa |

| Tensile strength of raw materials | ≤550Mpa |

| Coils OD | ≤Ф1600 mm |

| Coils ID | Ф508mm |

| Strips width | ≤750mm |

| Strips thickness | 2.3~4mm |

| Coils weight | ≤7000 kg |

| Line speed | 4 pcs/min(for sample Length 4320mm) |

Brand of main electrical components:

| Items Name | Brand |

| PLC | Mitsubishi, Japan |

| Servo system | Yaskawa , Japan |

| Inverter | Delta (Taiwan) |

| Touch Screen | Weinview(Taiwan) |

| Low voltage electrical appliances | Schneider (France) |

| DC speed controller | Eurotherm (USA) |

| Encoder | Omron(Japan) |

Product Detail Introduce

1.Automatic Decoiler with Loading Trolley

The machine is single support mode, motor driven uncoiler material shaft to release the material volume, hydraulic power drive uncoiler material shaft tensioning device, the material volume is fixed on the uncoiler material shaft,the tensioning structure is wedge type,more stable and reliable working condition

The uncoiler is automatic type , when the material after being installed on the uncoiler material shaft, in actual operation process of the whole line of decoiler material is active rotation axis, the traction from the uncoiler uncoiling mechanical and electrical machine can automatically according to the speed of the whole line for the release of the material in order to ensure the safety of decoiler operation decoiler is equipped with pneumatic brakes

The uncoiler also contains 4 baffle plates and a press arm to prevent the material from loosing in the uncoiling process and to ensure the safety of the operators

Coils ID:Ф508mm

Max. Coil OD:Ф1600mm

Max. Strips width:750 mm

Max. Coils weight:≤6000 kg

Uncoiler motor power:≈5.5kw(according the final design

2.Material Storage Devices

The material storage device consists of two parts: the arc-shaped idler roller and the material-supporting device. There are four sets of arc-shaped idler rollers, which are placed on both sides of the two storage bins, and are composed of an arc frame and a set of flexible idler rollers. , The surface of the roller is plated with hard chrome. A photoelectric switch is installed in the pit of the discharge bin to control the position of the material coil entering the pit, so that the speed of each working part can be perfectly matched

3.Special 400T hydraulic punching and cutting machine

It adopts hydraulic four-column press mode, economical and applicable, the speed of fast punching distance can be adjusted in the horizontal direction of the plate, and the punching distance can be changed through the electrical control system

4.Punching &Cutting composite

The punching machine is equipped with two complete sets of punching & cutting moulds .

Three-wave (beam) guardrail plate is equipped with a set of punching &Cutting mould, Can finish the punching 28 holes at end the guardrail and cutting in one time.The specific mold specifications shall be confirmed according to the punch drawing signed and confirmed by the buyer and the seller.

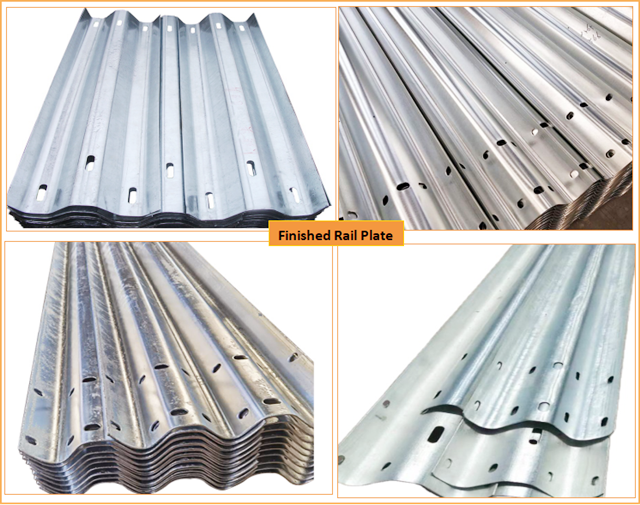

Workpiece show

Product detail pictures:

Related Product Guide:

We intention to see quality disfigurement within the creation and supply the ideal support to domestic and overseas buyers wholeheartedly for OEM manufacturer Vehical Bumper Beam Roll Forming Machine - Combined Two and Three Beam Roll Forming Machine – Raintech , The product will supply to all over the world, such as: kazan, Portugal, Kenya, What You Need Is What We Pursue.We are sure our products will bring you first class quality.And now sincerely hope to promote partner friendship with you from all over the world. Let's joint hands to cooperate with mutual benefits!

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.