Online Exporter Truck Bed Panels Roll Forming Machine - Hat Profile Roll Forming Machine – Raintech

Online Exporter Truck Bed Panels Roll Forming Machine - Hat Profile Roll Forming Machine – Raintech Detail:

PRODUCT DESCRIPTION

Uncoiler(Single head)

Allowable coil diameter: ф508

Maximum allowed outer diameter: ф1400mm

Allow the width of the maximum materials: <200 mm

Maximum load weight of material coil:≤ 2000 kg

Feature:The uncoiler is equipped with pneumatic brake device. Also contains 4 baffle plates to prevent the material from becoming loose in the uncoiling process.

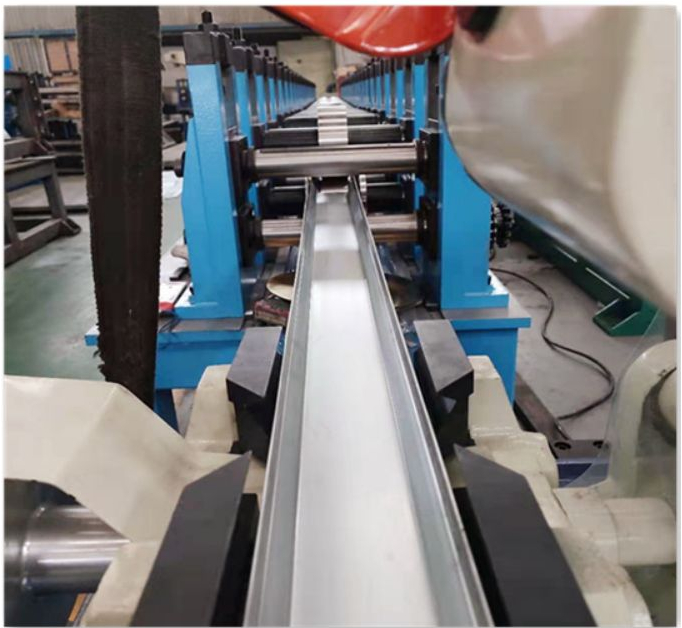

Roll Forming Machine

Roll Forming Machine adopts independent archway stands structure machine with individual gear box driven. Motor, reducer, helical bevel gear drive.

Archway stands material: QT450

Forming stations : 14

Independent transmission box advantage:

Each group of arches is equipped with an independent transmission box, which is directly connected to the lower shaft of the arch through coupling.

Motor Power: 11KW Siemens Motor

Maximum line speed: 5 ~ 30m/min

Forming Roller

The forming rollers designed by professional software. The material is made of high-quality die steel Cr12, and the hardness after quenching is HRC58~62 (equivalent to American material D2/D3). The roller surface is polished after finishing, with high precision and long service life.

Hydraulic system

The combination structure of pump and accumulator is adopted, the speed of punching and shearing action is fast, and the speed of production line is improved. The air-cooled cooler is used to dissipate heat to meet the production requirements under high load and higher temperature. The hydraulic system is a fast hydraulic system, suitable for high-speed punching, hole-rolling and shearing cold bending production lines

Electrical control units

The whole line adopts PLC and touch screen combined man-machine control mode. Specifications, quantity and parameters of parts can be set by touch screen, and multiple sets of operation instructions can be stored at one time. High degree of automation, it has alarm function in the case of abnormal production line, and the operation of the whole production line can be monitored through the control system. After power failure or abnormal shutdown, it can continue processing according to the working parameters set before.

Hydraulic Servo moveable cutting machine

Services tracking speed:30m/min

The cutting mode: Single blade

Material: DC53 (The hardness after quenching isHRC58 ~ 62)

Fixed ruler accuracy:± 0.5mm

Servo motor power:3KW

Feature:Cut the formed parts to certain length, without stopping during the cutting process, with high speed and high efficiency

WORKPIECE

Product detail pictures:

Related Product Guide:

Our pursuit and enterprise goal is to "Always satisfy our customer requirements". We keep on to establish and style and design outstanding top quality goods for both our outdated and new prospects and realize a win-win prospect for our clientele likewise as us for Online Exporter Truck Bed Panels Roll Forming Machine - Hat Profile Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Mauritius, Uruguay, Montreal, We follow up the career and aspiration of our elder generation, and we're eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have now a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.