Original Factory Corrugated Curving Machine - Storage Shelf Rack Roll Forming Machine – Raintech

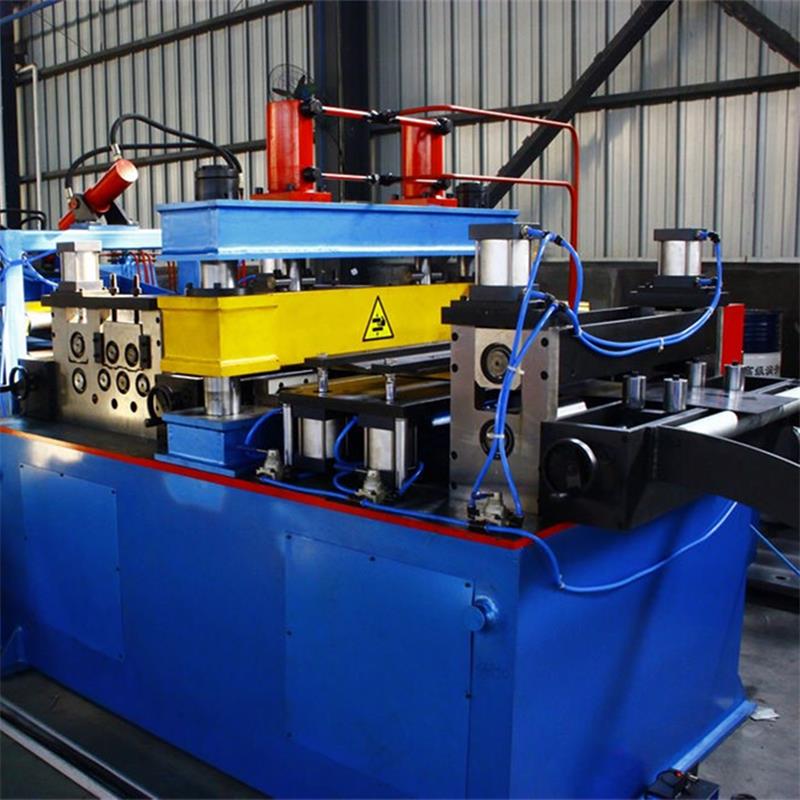

Original Factory Corrugated Curving Machine - Storage Shelf Rack Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

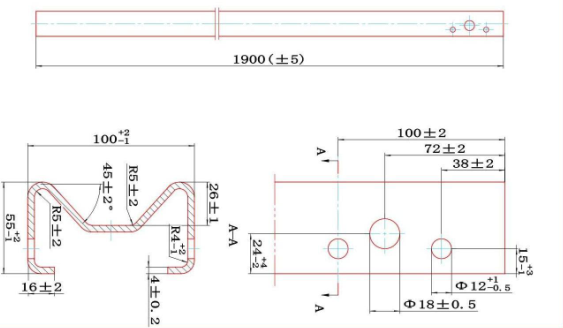

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Product detail pictures:

Related Product Guide:

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Original Factory Corrugated Curving Machine - Storage Shelf Rack Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Switzerland, Austria, Buenos Aires, When It produced, it making use of the world's major method for reliable operation, a low failure price, it appropriate for Jeddah shoppers choice. Our enterprise. s situated inside the national civilized cities, the website traffic is very hassle-free, unique geographical and financial circumstances. We pursue a "people-oriented, meticulous manufacturing, brainstorm, make brilliant" company philosophy. Strict good quality management, fantastic service, affordable cost in Jeddah is our stand around the premise of competitors. If needed, welcome to make contact with us by our web page or phone consultation, we will be delighted to serve you.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.