Personlized Products Corrugated Roll Making Machine - Roller Shutter Door Roll Forming Machine – Raintech

Personlized Products Corrugated Roll Making Machine - Roller Shutter Door Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

Allowable coil ID: Ф508

Maximum allowable roll diameter: Ф1500mm

Maximum allowable roll width: 200 mm

Maximum roll carrying weight: ≤2000 kg

Archway material: QT450.

Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50

Parameters: Forming passes: 14 passes (subject to the final design)

Shaft diameter of forming machine: φ50mm (subject to final design)

Motor power: 5kw DC motor (Nanyang or Ace)

Maximum linear speed: 2~8m/min

MAIN COMPONENTS

3.1 2 ton single head unpowered decoiler 1 set

Uncoiling: The machine is in single-head mode. Single support, manually fix the material roll on the uncoiler material shaft.The working condition is stable and reliable.

3.2 Feeding Guide 1set

Feeding guide, reasonable design, can be fixed on one side and movable on the other side, the screw rod is adjusted, and the position display shows the scale.

The guide plates on both sides of the plate are heat treated to ensure the hardness.

3.3 Precision roll forming unit 1set

There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft).

3.4 Hydraulic Shearing:

Stop shearing, cutting adopts blanking cutting to ensure the integrity of the arc part.

3.5 Electrical control system:

| No | Item Name | Brand |

| 1 | PLC | Schneider |

| 2 | Inverter | Schneider |

| 3 | Low-voltage electrical appliances | Schneider |

| 4 | Encoder | Schneider/Omron |

| 5 | Touch screen | Vinylon |

3.6 Hydraulic System:

The hydraulic system is a fast hydraulic system, suitable for high-speed punching, perforating rolls and shearing cold bending production lines. The main hydraulic components adopt Beijing Huade products.

The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic tank,

The hydraulic system adopts a filter, and the cleanliness of the oil is guaranteed to be level 6-8.

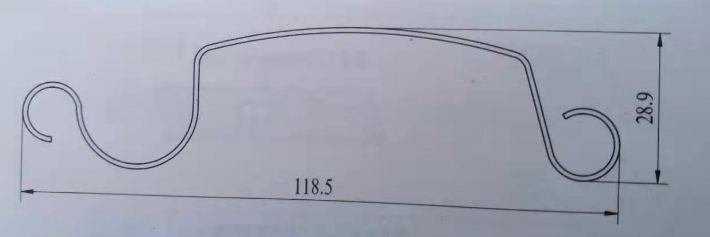

WORKPIECE SAMPLES

Roller shutter door roll forming machine; roller shutter door making machine; rolling shutter door machine.

Product detail pictures:

Related Product Guide:

In the past few years, our business absorbed and digested advanced technologies both equally at home and abroad. In the meantime, our company staffs a group of experts devoted to your advancement of Personlized Products Corrugated Roll Making Machine - Roller Shutter Door Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Uganda, Bahamas, French, They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We have been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

The sales manager has a good English level and skilled professional knowledge, we have a good communication. He is a warm and cheerful man, we have a pleasant cooperation and we became very good friends in private.