Professional China Roofing Sheet Roll Forming Machine - Storage Shelf Rack Roll Forming Machine – Raintech

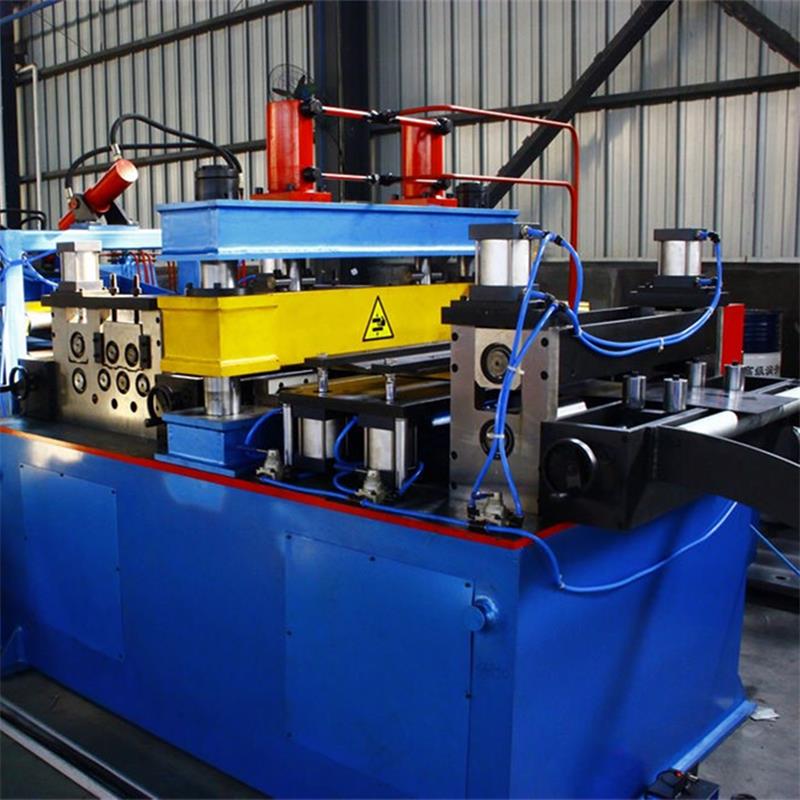

Professional China Roofing Sheet Roll Forming Machine - Storage Shelf Rack Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| Configurations | 3T Manual Uncoiler(2 SETS), Roll Forming, Electric-Motor, Mould Cutting, hydraulic station, Control Cabinet |

| Control System | Automatic Colored Touch ScreenDelta brand PLC Inverter |

| Main Power | 7.5 KW |

| Pump Power | 4 KW |

| Power Supply | 380V, 3-Phase, 50Hz |

| Forming Speed | 8-10 m/min |

| Roll Station | 17 roller station |

| Shaft Diameter | 57mm |

| Feeding Thickness | 1.8mm |

| Overall Size | About 7200×1200×1500mm |

| Total Weight | Approximately 3600KGS |

PRODUCTION PROCESS

Uncoiling → Leveling → Servo Feeding → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

Uncoiler: automatically release the material coil according to the speed of the whole line

Servo Feeding Machine: Feed the sheet according to the actual step length required for punching

Punching press: Used to punching holes in the plate

Roll Forming Machine: Used to achieve the final required interface shape through the roll forming process of the required finished plate shape

Cutting Machine: It is to cut the formed work piece to length

Electrical Control Unit: The unit is equipped with PLC and tough screen, it control the whole production line.

Hydraulic Station: Provide power for punching machine and cutting machine

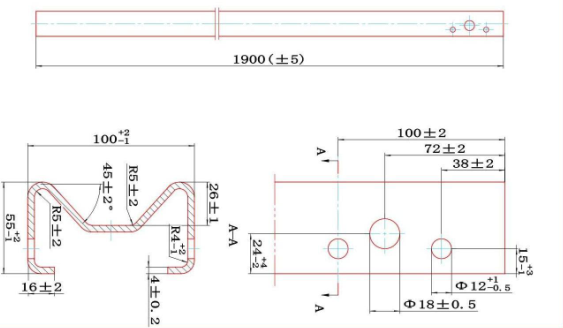

WORKPIECE SAMPLES

APPLICATION

The roll forming production line is used to produce storage racks for warehouse and storage frame.

Product detail pictures:

Related Product Guide:

With dependable high-quality method, fantastic standing and ideal purchaser assistance, the series of products produced by our firm are exported to many countries and regions for Professional China Roofing Sheet Roll Forming Machine - Storage Shelf Rack Roll Forming Machine – Raintech , The product will supply to all over the world, such as: New Delhi, Toronto, Angola, We believe with our consistently excellent service you can get the best performance and cost least products from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!