Special Design for Corrugated Iron Rolling Machine - Floor Decking Roll Forming Machine – Raintech

Special Design for Corrugated Iron Rolling Machine - Floor Decking Roll Forming Machine – Raintech Detail:

PRODUCT APPLICATION

MAIN TECHNICAL PARAMETERS

Material: Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MAIN COMPOSITIONS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coil ID: Ф508; Coil OD: Ф1300mm; Strips width: 1450 mm; Max. Weight: ≤10000 kg |

| 2 | Roll Forming Machine |

Structure: the forming unit is driven by motor reducer chain; Forming stations:36 stations; Forming machine shaft dia:φ95mm; Motor power: 22kwX2; Max: 15m/min |

| 3 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy:±1.5mm |

| 4 | Electrical Control Cabinet |

Main electrical components; PLC: Mitsubishi; Inverter: delta ; Touch screen: veron (Taiwan, China) ; Low-voltage electrical appliances: schneider (France) ; Encoder: Omron (Japan) |

| 5 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

| Run-out Table | Size: 3*1.2*0.6m; Adjustable Height |

PRODUCTION PROCESS

Uncoling → Flatterning → Roll Forming → Dischaging

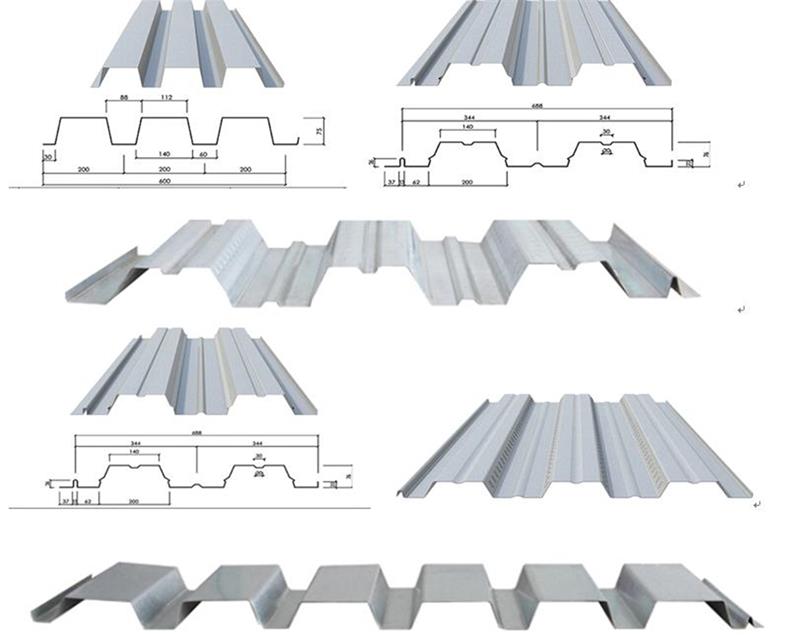

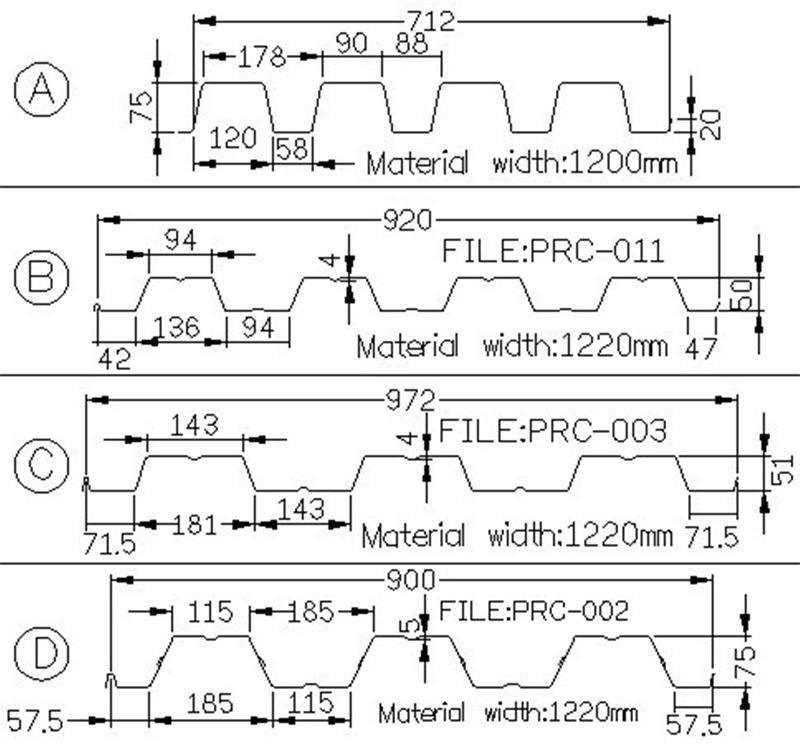

WORKPIECE SAMPLES

Metal decking is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

Product detail pictures:

Related Product Guide:

we can easily offer you high-quality products and solutions, competitive rate and very best shopper support. Our destination is "You come here with difficulty and we give you a smile to take away" for Special Design for Corrugated Iron Rolling Machine - Floor Decking Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Belgium, Norway, Toronto, With a wide range, good quality, reasonable prices and stylish designs, our items are extensively used in this field and other industries. We welcome new and old customers from all walks of life to contact us for future business relationships and achieving mutual success! We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.