100% Original Factory 76mm High Deck Floor Roll Forming Machine Construction Deck Making Machinery

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for 100% Original Factory 76mm High Deck Floor Roll Forming Machine Construction Deck Making Machinery, Your guidance is our everlasting electrical power! Warmly welcome clients in your own home and overseas to go to our organization.

Our aim is usually to give superior quality items at aggressive rates, and top-notch company to clients around the earth. We have been ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for China Deck Floor Forming Machine and Floor Deck Forming Machine, We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We are going to always believe in and work on it. Welcome to join us to promote green light, together we are going to make a better Future!

PRODUCT APPLICATION

MAIN TECHNICAL PARAMETERS

Material: Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MAIN COMPOSITIONS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coil ID: Ф508; Coil OD: Ф1300mm; Strips width: 1450 mm; Max. Weight: ≤10000 kg |

| 2 | Roll Forming Machine |

Structure: the forming unit is driven by motor reducer chain; Forming stations:36 stations; Forming machine shaft dia:φ95mm; Motor power: 22kwX2; Max: 15m/min |

| 3 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy:±1.5mm |

| 4 | Electrical Control Cabinet |

Main electrical components; PLC: Mitsubishi; Inverter: delta ; Touch screen: veron (Taiwan, China) ; Low-voltage electrical appliances: schneider (France) ; Encoder: Omron (Japan) |

| 5 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

| Run-out Table | Size: 3*1.2*0.6m; Adjustable Height |

PRODUCTION PROCESS

Uncoling → Flatterning → Roll Forming → Dischaging

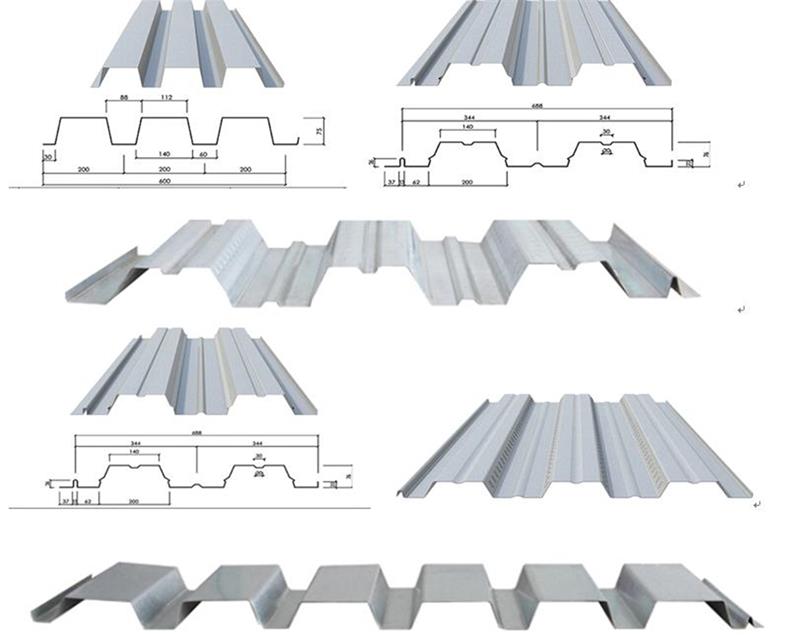

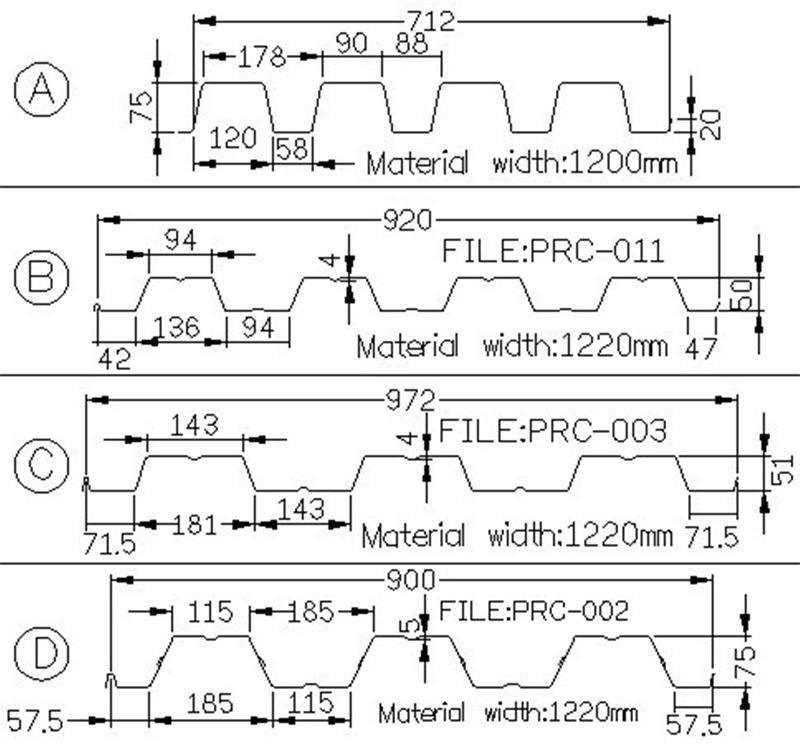

WORKPIECE SAMPLES

Metal decking is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

Floor roll forming machines are machines used to produce decorative floor panels or boards.

These machines typically consist of a series of roll-forming stations that shape and bend metal coils into the desired profile for floor panels. The process begins by feeding a metal coil into a machine, which passes through a series of rollers and stations. These rollers gradually shape and bend the metal into the desired profile. Roll forming stations can be customized according to the specific requirements of the project to produce different types of floor decking. Floor roll forming machines come with a variety of features and capabilities, including adjustable roller gaps, computer controls, and automatic cutting systems. These features enable precise and efficient production of floor decorative panels. After the metal is formed, it is cut to the desired length using an integrated cutting system. The cut panels are then stacked or packaged for shipping or further processing. Floor panels produced by these machines are commonly used in the construction industry for flooring applications in commercial and industrial buildings. These panels are known for their strength, durability and ease of installation.

Overall, floor decking roll forming machines play a vital role in manufacturing high-quality floor decking to meet the needs of the construction industry.