2019 China New Design Hat/C/U/C Profile Channel Roll Forming Machine

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for 2019 China New Design Hat/C/U/C Profile Channel Roll Forming Machine, We welcome new and aged prospects from all walks of everyday living to get hold of us for long term enterprise associations and attaining mutual accomplishment!

carry on to further improve, to guarantee merchandise high-quality in line with market and buyer standard necessities. Our organization has a top quality assurance procedure have already been established for China Hat Profile Roll Forming Machine and H Purlin Roll Forming Machine, Our products are widely recognized and trusted by users and can meet continuously changing of economic and social needs. We welcome new and old customers from all walks of life to contact us for future business relationships and mutual success!

PRODUCT DESCRIPTION

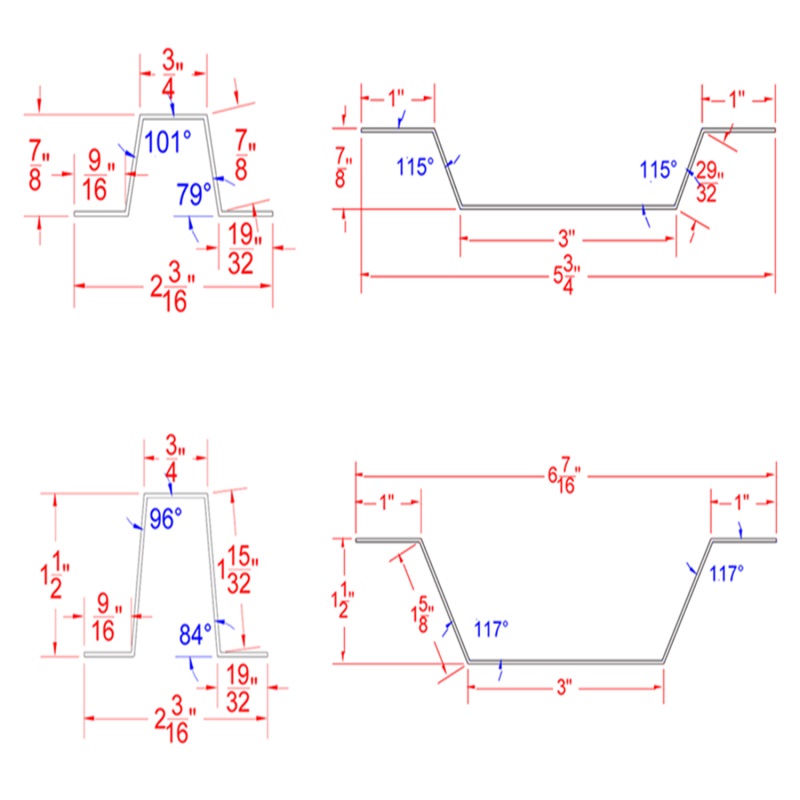

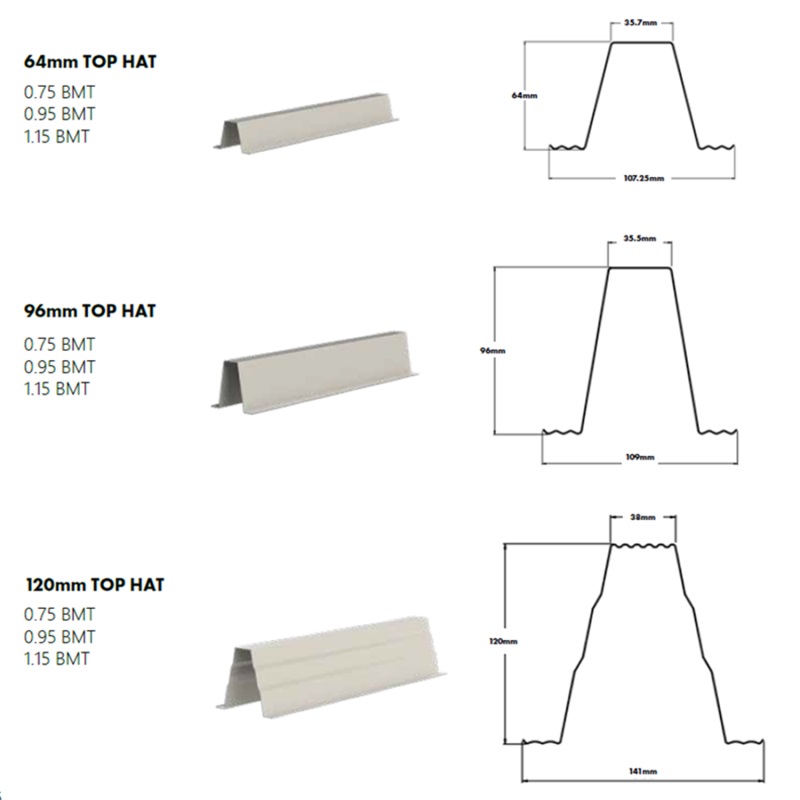

Hat channels are an alternative type of steel roof framing system, which can also be used as a purlin where a lower profile is required, or where the cover system requires closer purlin spacing thus making standard “Z” or “C” purlins overly expensive.

Our hat profile roll forming machine is for making the hat channels, which widely applicable in metal/steel roof construction industries.

MAIN TECHNICAL PARAMETERS

| 1 | Machine structure | Individual archway stands structure |

| 2 | Total power | Motor power-18.5kw Hydraulic power-5.5kw |

| 3 | Roller stations | 18 dots stations |

| 4 | Productivity | 15-25m/min |

| 5 | Decoiler | 3T hydraulic decoiler |

| 6 | Leverling part | Upper is 3 rollers, down is 4 stations(total is 7 rollers) |

| 7 | Drive system | By independent gearbox |

| 8 | Diameter of shaft | ¢60mm solid shaft |

| 9 | Roller material | American D2 D3 |

| 10 | Pre punching& cutting system | Pre-cutting to change the material Material of the punching mold: Cr12 |

| 11 | Hydraulic cutting system | Cr12 with heat treatment 58-60° |

| 12 | Hydraulic power | 7.5KW |

MAIN COMPOSITIONS

|

1 |

Automatic De-coiler | 1. Single head design 2. Loading weight: 3Tons 3. Hydraulic automatic expansion and tightening 4. Suitable width: <300mm 5. Coil ID: ¢500±20mm 6. Coil OD: ≤1200mm |

|

2 |

Servo Feeding Leveling | 1. It adopts 5 rollers for leveling, 2 pairs of guide rollers 2. Maximum leveling roll width: 300mm 3. Adapt to the maximum roll thickness: 1~2mm 4. Maximum working speed: 20 m/min 5. Driven: servo motor |

|

3 |

Multi-functional Punching Machine | 1. 6 punching stations, 2. Servo motor power: 1.3KW 3. Servo motor brand: Japan Yaskawa 4. Suitable width: <300mm 5. Punching mold fast positioning, repeat positioning. |

|

4 |

Roll Forming Machine | 1. Driven system: Motor, reducer, spiral bevel gear drive 2. Main machine power: 15KW*2 Sets, 3. Motor brand: SIEMENS BADE servo motor 4. Module Components fast positioning, repeat positioning 5. Forming stations: 18 groups stations |

|

5 |

Hydraulic Cutting Machine | 1. Hydraulic single station, 2. Cutting force: 30Tons, 3. Cutting type: stop cutting 4. Module Components fast positioning, repeat positioning |

|

6 |

Computer Control Box | 1. Japan Mitsubishi motion controller PLC 2. Japan Yaskawa Servo System 3. With human machine interface touch screen 4. Schneider weak current control |

|

7 |

Hydraulic Station | 1. Hydraulic system power: 15KW 2. Hydraulic value: Huade, 3. With fan cooling system |

PRODUCTION PROCESS

Uncoiling → leveling → Looper (storage) → servo feeding → Multi-stations punching → forming station → Hydraulic cutting → Finished product discharging

WORKPIECE SAMPLES

Hat channel roll forming machine;hat profile forming machine;hat profile channel making machine

The hat channel forming machine is an industrial equipment used to produce hat-shaped metal channels, also known as rubber band channels or elastic channels. These channels are commonly used in the construction industry to provide a resilient mounting surface for drywall or other ceiling and wall building materials.

A roll forming machine consists of a series of rollers that progressively form flat metal strip into the desired hat groove profile. The machine usually consists of an uncoiler for securing and feeding the metal strip, a leveling and cutting system for preparing the strip for forming, a series of forming stations with adjustable rollers and for separating the finished lanes into required lengths cutting system. The process begins by feeding the metal strip into the machine through an uncoiler. The strip goes through a leveling and cutting system to ensure that the metal piece is flat and straight. It then passes through a series of forming stations where each roller progressively forms the metal strip into a hat channel profile. Finally, a cutting system divides the formed channel into the required lengths. The speed and precision of the hat channel roll forming machine can be controlled using the control panel. Some machines also include features such as automatic lubrication systems and computer control systems for easy operation and maintenance.

Overall, hat channel roll forming machines are essential for the efficient and accurate production of hat shaped metal channels used in a variety of construction applications.