2023 Good Quality Shelves Rack Pillar Beam Upright Pillar Roll Forming Machine Rack System Forming Machine for Warehouse

Quality Initial,and Shopper Supreme is our guideline to offer the best support to our shoppers.Nowadays, we’re seeking our greatest to be one of the most beneficial exporters in our field to satisfy customers a lot more need for 2023 Good Quality Shelves Rack Pillar Beam Upright Pillar Roll Forming Machine Rack System Forming Machine for Warehouse, To improved expand market, we sincerely invite ambitious individuals and providers to hitch as an agent.

Quality Initial,and Shopper Supreme is our guideline to offer the best support to our shoppers.Nowadays, we’re seeking our greatest to be one of the most beneficial exporters in our field to satisfy customers a lot more need for China Rack System Roll Forming Machine and Rack System Forming Machine, For more than ten years experience in this filed, our company has gained high reputation from home and abroad. So we welcome friends from all over the world to come and contact us, not only for business, but also for friendship.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

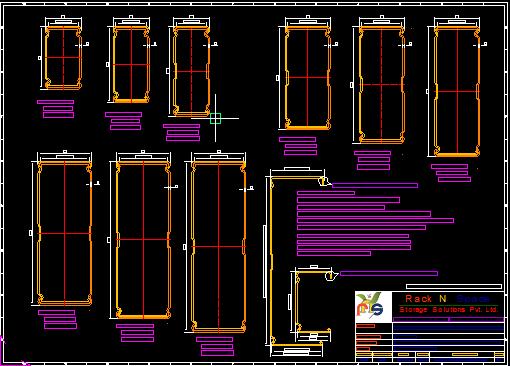

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

A Warehouse Shelf Transom Roll Forming Machine is a machine used to manufacture metal beams, typically used in warehouses or retail stores for storage shelving. The machine uses a continuous bending and forming process to produce long, narrow metal beams with consistent dimensions. The raw material used in this machine can be galvanized steel, stainless steel, aluminum or other metals.

The storage shelf beam roll forming machine is composed of uncoiler, feeding device, roll forming unit, cutting device, control system, discharge table and other parts. The uncoiler grips and uncoils the metal coil, while the feeder feeds the metal into the roll forming unit. A roll forming unit consists of multiple rollers that form metal into beams through a continuous bending and forming process. After the beam is formed, the cutting device separates it from the rest of the coils, and the control system controls the operation of the entire machine. Finally, the export table collects the finished beams for further processing or use.

Overall, storage rack beam roll forming machines are useful tools in the manufacturing industry for producing high-quality metal beams for storage and retail shelving.