Factory Customized Hot Sale Mexico B Type 36′′ Metal Floor Deck Sheet Cold Roll Forming Machine

The organization keeps into the procedure concept “scientific administration, premium quality and effectiveness primacy, consumer supreme for Factory Customized Hot Sale Mexico B Type 36′′ Metal Floor Deck Sheet Cold Roll Forming Machine, As a key enterprise of this industry, our corporation makes endeavours to become a leading supplier, dependant on the faith of expert quality & all over the world provider.

The organization keeps into the procedure concept “scientific administration, premium quality and effectiveness primacy, consumer supreme for China Roll Forming Machine and Tile Making Machine, Our company promises: reasonable prices, short production time and satisfactory after-sales service, we also welcome you to visit our factory at any time you want. Wish we have now a pleasant and long terms business together!!!

PRODUCT APPLICATION

MAIN TECHNICAL PARAMETERS

Material: Galvanized cold-rolled sheet

Yield strength of raw materials: ≤275Mpa

Tensile strength of raw materials: ≤550Mpa

Coil OD: ≤Ф1300 mm

Coil ID: Ф508

Strips width: ≤1450mm

Strips thickness: 0.8~1.2mm

Coil weight: ≤10000 kg

MAIN COMPOSITIONS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support; Coil ID: Ф508; Coil OD: Ф1300mm; Strips width: 1450 mm; Max. Weight: ≤10000 kg |

| 2 | Roll Forming Machine |

Structure: the forming unit is driven by motor reducer chain; Forming stations:36 stations; Forming machine shaft dia:φ95mm; Motor power: 22kwX2; Max: 15m/min |

| 3 | Hydraulic Cutting | The cutter mode adopts blanking shearing; Blade material: Cr12MoV (hardness after quenching HRC58~62); Parameter: cutting accuracy:±1.5mm |

| 4 | Electrical Control Cabinet |

Main electrical components; PLC: Mitsubishi; Inverter: delta ; Touch screen: veron (Taiwan, China) ; Low-voltage electrical appliances: schneider (France) ; Encoder: Omron (Japan) |

| 5 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

| Run-out Table | Size: 3*1.2*0.6m; Adjustable Height |

PRODUCTION PROCESS

Uncoling → Flatterning → Roll Forming → Dischaging

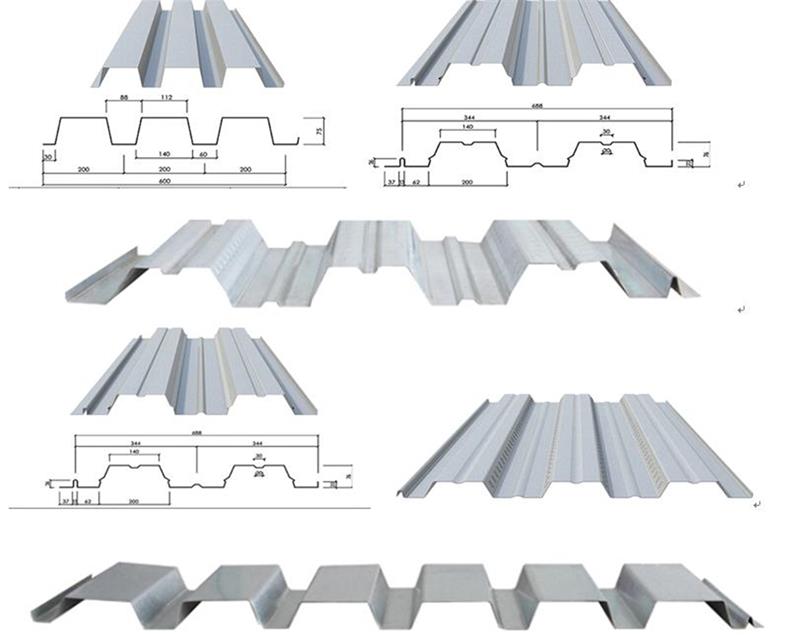

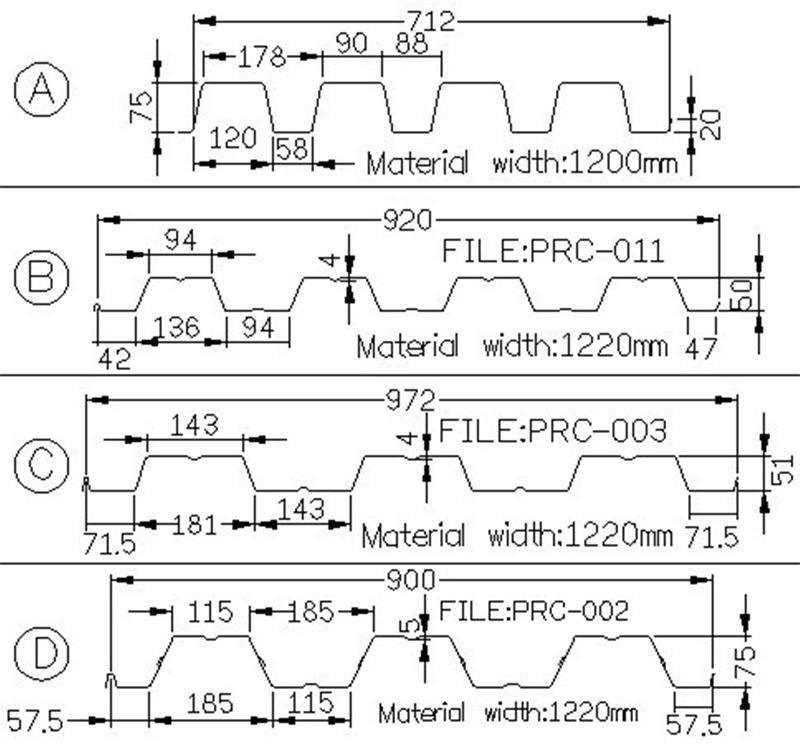

WORKPIECE SAMPLES

Metal decking is corrugated metal sheeting that’s used as a structural roof deck or composite floor deck. It will be supported by steel beams or joists The purpose of metal deck is to support the insulating membrane of a roof or to support and bond with the concrete to create a composite metal floor deck.

The floor slab forming machine is a kind of equipment used in the construction industry to produce floor slabs or panels. These panels are commonly used in buildings to provide a stable and durable flooring system.

A roll forming machine takes a roll of sheet metal (usually steel) and feeds it through a series of rollers. As the sheet passes through each set of rollers, it is gradually shaped and formed into the desired profile. For floor trim panels, the machine will form corrugated or trapezoidal shapes with stiffeners for added strength. Once the sheet metal is formed, it is cut to the desired length with a flying saw or hydraulic shears. The cut panels are then stacked and ready to install. Floor roll forming machines typically consist of multiple stations, each equipped with a set of rollers and tools to form a specific profile or feature.

The machine is controlled by a computer system, which can accurately set parameters such as roll position and cutting length. The floor produced by this machine has the advantages of quick and easy installation, high load-bearing capacity and fire resistance. They are commonly used in commercial and industrial buildings as well as residential construction projects.

Overall, floor roll forming machines are an important tool in the efficient and precise manufacture of floor panels, enabling the construction industry to build strong and durable floor systems.