Fixed Competitive Price Corrugated Sheet Rolling Machine - Storage Shelf Beam Roll Forming Machine – Raintech

Fixed Competitive Price Corrugated Sheet Rolling Machine - Storage Shelf Beam Roll Forming Machine – Raintech Detail:

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

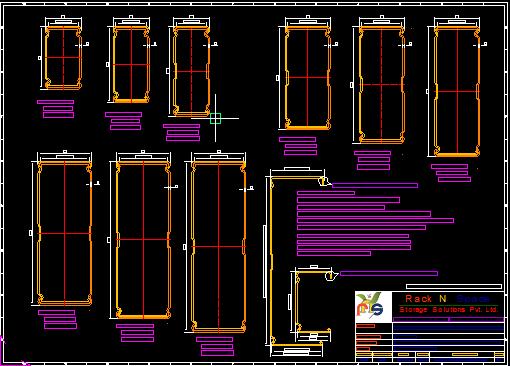

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for Fixed Competitive Price Corrugated Sheet Rolling Machine - Storage Shelf Beam Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Chile, Hamburg, United Kingdom, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.