Good Quality Roof Tile Forming Machine - Channel Drawer Slide Roll Forming Machine – Raintech

Good Quality Roof Tile Forming Machine - Channel Drawer Slide Roll Forming Machine – Raintech Detail:

BRIEF INTRODUCTION

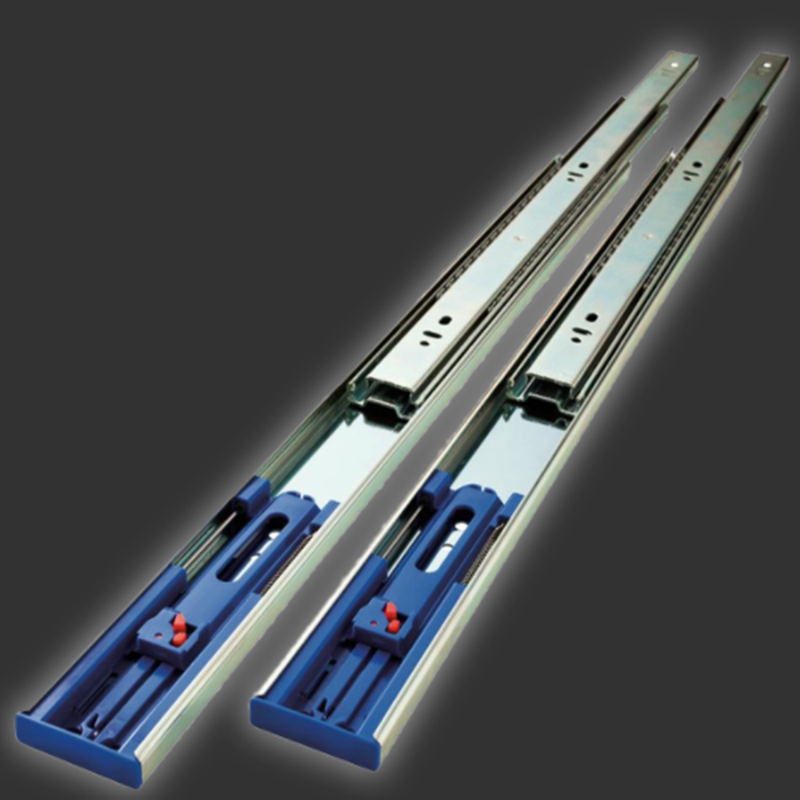

This slide rail assembly is composed of three layers of skeleton cold-formed parts “1″, “2″, and “3″, as well as balls and cages in the middle. The three layers of skeletons “1″, “2″, and “3″ can be composed of Fast Changing Telescopic Channel Drawer Slide Roll Forming Machine production.

MAIN TECHNICAL PARAMETERS

Material quality: cold rolled steel, Galvanized steel, stainless steel

Yield strength of raw materials: 235Mpa

Coil outer diameter: ≤Ф1200 mm

Inner diameter of coil: Ф508mm

Strip width: ≤100mm

Strip thickness: 1.2mm, 1.2mm, 1.5mm

Single coil weight: ≤2500 kg

MACHINE CONFIGURATION&SPECIFICATIONS

1. MANUAL UNCOILER 1SET

This machine is in single-head mode.

2. LEVELING 1 SET

It adopts 7 rollers for leveling, 2 pairs of guide rollers, and the feed rollers are pneumatically clamped and controlled by a servo motor.

3. 163T PUNCHING PRESS 1 SET

The punching distance is adjustable in the transverse direction of the plate, and the punching step can be changed through the electrical control system. each length specification is equipped with 1 set of dies separately.

4. FAST CHANGING ROLL FORMING UNIT 1 SET

When replacing products with different specifications, only the part of the partition sleeve needs to be replaced, and the product can be replaced quickly

Parameters:

No. of forming passes: 12

Archway number: 10+12+8=30

Shaft diameter of forming machine: φ50mm (subject to final design)

Motor power: about 7.5kW (subject to the final design)

Maximum linear speed: 10~15m/min

5. SERVO TRACKING CUTTING 1 SET

Use servo tracking to cut off, fast speed and high efficiency.Cutter material: Cr12MoV (hardness after quenching is HRC58~62)

6. ELECTRICAL CONTROL UNIT 1 SET

The whole line adopts the man-machine control mode combining PLC and touch screen. The specification parameters, quantity and system parameters of the parts can be set through the touch screen.

|

Brand of main electrical components |

||

| 1. | PLC | Mitsubishi,Japan |

| 2. | Servo Motor | Yaskawa,Japan |

| 3. | Inverter | Delta (Taiwan, China) |

| 4. | Touch screen | Vinylon (Taiwan, China) |

7. HYDRAULIC STATIONS 1 SET

The main components are: oil pump, motor, hydraulic valve, solenoid valve, filter and hydraulic oil tank, etc.

PRODUCTION PROCESS

Uncoiling → Leveling Servo Feeding → Punching → Cold Roll Forming → Servo Tracking Cutting → Discharging

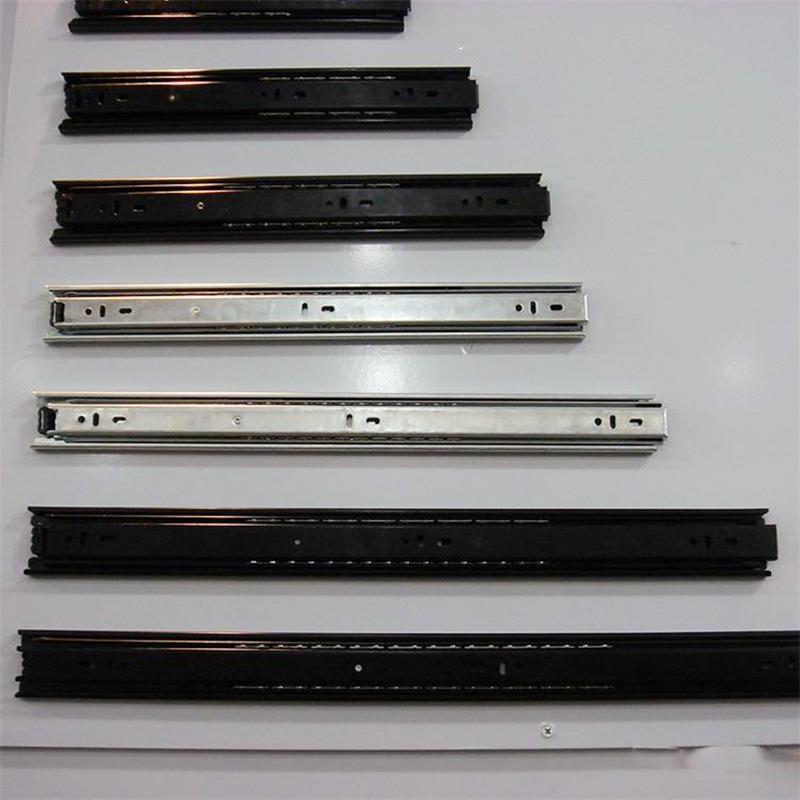

WORKPIECE SAMPLES

Drawer slides roll forming machine;drawer slide making machine;telescopic drawer slide roll forming machine;channel drawer slide roll forming machine

Product detail pictures:

Related Product Guide:

Our products and solutions are greatly recognized and trustworthy by customers and may fulfill constantly changing financial and social requires for Good Quality Roof Tile Forming Machine - Channel Drawer Slide Roll Forming Machine – Raintech , The product will supply to all over the world, such as: Mali, Albania, Oslo, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

Problems can be quickly and effectively resolved, it is worth to be trust and working together.