Good Wholesale Vendors High Precision Cable Tray Roll Forming Machine

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for Good Wholesale Vendors High Precision Cable Tray Roll Forming Machine, We now have developed a responsible name amongst many customers. Quality&customer very first are usually our constant pursuit. We spare no endeavours to help make much better solutions. Look forward to long-term cooperation and mutual advantages!

We are going to make every single effort for being excellent and excellent, and accelerate our ways for standing while in the rank of international top-grade and high-tech enterprises for China Cable Tray Roll Forming and Cable Tray Forming, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

PRODUCTION DESCRIPTIONA

This cable tray production line is a specially equipment for cable tray roll forming,also can finish the production of its cover plate, which widely applicable in power transmission, machinery and equipment, commercial buildings and other facilities, including computer rooms, parking lots, data centers, offices, Internet service providers, hospitals, schools/universities, airports and factories, etc.

MAIN TECHNICAL PARAMETERS

| No | Model: SART-1250*2.5 | Specification |

| 1 | Material | CR/HR/G. I steel |

| 2 | Coil OD | Ф1200 mm |

| 3 | Coil ID | Ф508mm |

| 4 | Strips width | <1250mm |

| 5 | Strips Thickness | 0.5~2.5mm |

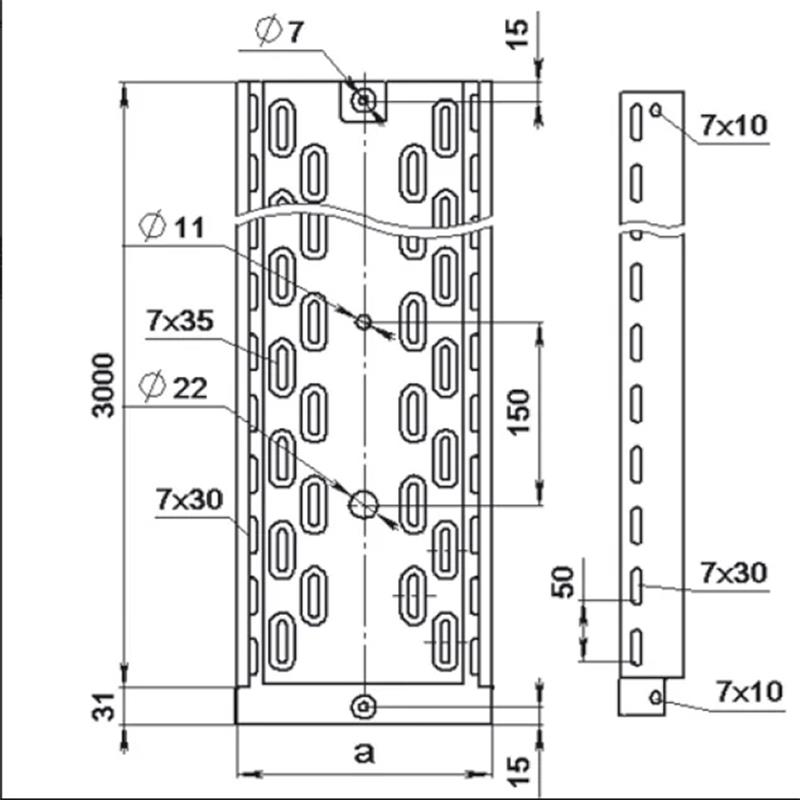

| 6 | Cable Tray Width | 100~800mm |

| 7 | Cable Tray Height | 50~200mm |

| 8 | Coils weight | ≤10000 kg |

| 9 | Electrical power | 415V,50Hz,3phase |

| 10 | Line Speed | 5~15m/min |

MAIN COMPONENTS

This production line is mainly composed by following parts:

1. Uncoiler. 1 set

Single support,four-bar tension structure, tension force comes from hydraulic cylinder, adjustment is fast and reliable.

2. Leveler. 1 set

It adopts 7 rollers for leveling, 2 pairs of guide rollers, feed rollers are pneumatically clamped, frequency conversion speed regulation, switch control.

3. Looper ( Storage Material) 1 set

Used to buffer the speed mismatch between the unwinding and leveling and the punching machine, and correct the deviation;

4. Servo Feeder. 1 set

The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick.

5. Multi-stations Punching&Cutting Unit 1 set

It adopts liquid four-column press mode, which is economical, applicable and fast. The punching machine has a 6-station punching mode and contains 3 to 4 sets of die sets, which can continuously punch out multiple types of holes.

6. Cantilever adjustable forming machine 1 set

The forming unit adopts the cantilever forming machine mode. Motor, reducer, spiral bevel gear drive.When producing products with different bottom widths and waist heights, you only need to set the parameters on the touch screen, which is convenient, fast and reliable.

PRODUCTION PROCESS

Uncoiler → Leveler → Loop (storage) → Sevo Motor → multi-stations punching machine(cutting)→ Finished Products

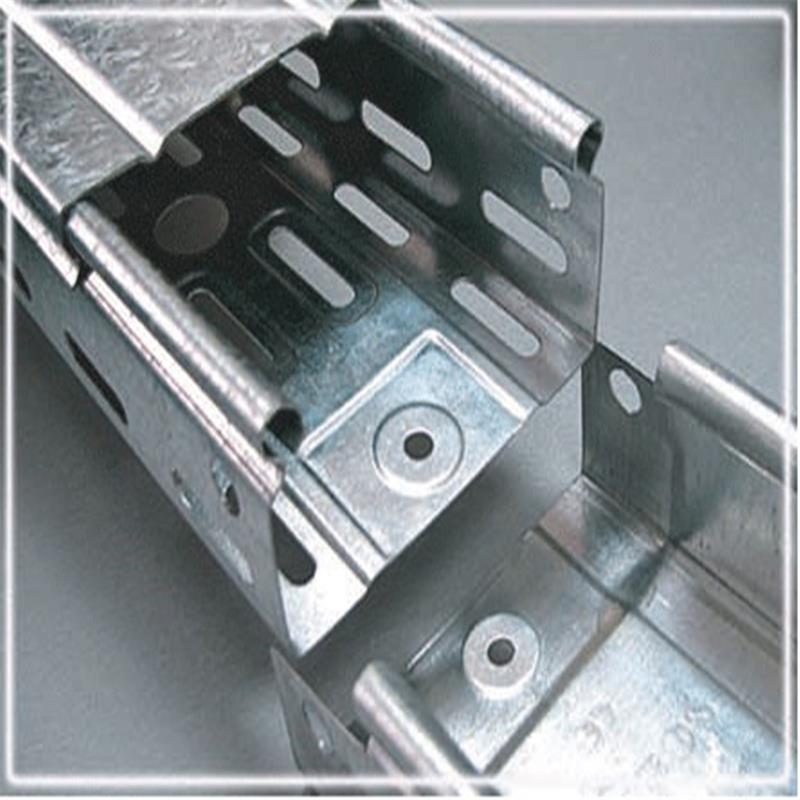

WORKPIECE SAMPLES

Cable tray roll forming machine / cable bridge making machine / electrical cable tray forming production line / cable cover making machine / cable tray making machine / able bridge roll forming production line.

The cable tray forming machine is a special machine for manufacturing cable trays. It is designed to produce cable trays of various sizes and shapes by continuously feeding coils of metal into the machine, which are fed through a series of rollers that shape the metal into the desired cable tray profile.

The flow forming process involves several stations, each with a set of rollers that progressively bend, form and cut the metal strip into the desired shape. The machine is usually equipped with decoiler, straightening unit, punching unit, roll forming unit and cutting unit.

The cable tray forming machine has high operation precision and high efficiency, which ensures the consistency of cable tray production, accurate size and high quality. It is commonly used in manufacturing facilities, construction sites and electrical installations where cable management is required.

Some key features and benefits of cable tray roll forming machines include:

Customization: The machine can be customized to produce cable trays in different sizes, shapes and materials such as steel or aluminium.

High Productivity: The machine can produce cable trays at high speed, which helps to increase productivity and meet demand.

Accuracy: The roll forming process ensures precise shaping and cutting of the metal strip, resulting in cable trays with exact dimensions and smooth edges.

Cost Effective: This machine helps to reduce labor costs by automating the cable tray production process, thus eliminating the need for manual labor.

Ease of Operation: The Cable Tray Roll Forming Machine is designed for ease of use, with intuitive controls and a user-friendly interface.

Overall, the cable tray roll forming machine is an essential tool for the efficient and reliable production of cable trays, providing a cost-effective solution for cable management in various industries.