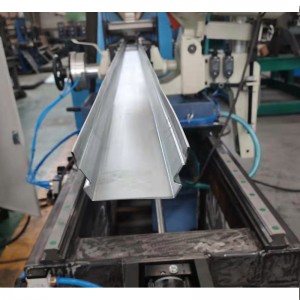

Hat Profile Roll Forming Machine

-

Raintech Hat Channel Roll Forming Machine Cold Rolled Bending Machine for Profiles

Production process flow

Uncoiling (including automatic feeding trolley) → leveling and guiding → roll forming (including straightening) → cutting.1. Uncoiling:

The machine is in single-head mode, single support and manual tightening.

2. Servo Leveling Feeder:

The machine adopts 5 rollers for leveling and feeding (2 rollers on the upper layer, 3 rollers on the lower layer, screw adjustment), 1 pair of guide rollers, the feeding rollers are pneumatically clamped, and the servo motor provides power for it.

3. Roll Forming Machine

Used to achieve the final required shape through the roll forming process of the required finished plate. The material is made of high-quality mold steel Cr12, and the hardness after quenching reaches HRC58~62 (physical characteristics are equivalent to American material D2), which improves mechanical performance and life. The surface of the roller is polished after finishing. The roller has high precision and long life.

4. Cutting

Structure: power saw head, servo tracking system, base, special fixtureDetailed Photos: