OEM Factory for Tube Mill Production Line - Tube and Pipe Mills High Frequency Welding Production Line – Raintech

OEM Factory for Tube Mill Production Line - Tube and Pipe Mills High Frequency Welding Production Line – Raintech Detail:

PROCESSING OBJECTS AND REQUIREMENTS

Purpose: The tube mill line is mainly used for polishing the outside surface of the stainless steel

The workpiece range requirements:

1.Workpiece diameter range:19-76mm

2.Workpiece length range:6000mm

3.Final surface roughness:Ra 0.1 (Through surface friction many times)

4.Final finish requirements: Grinding and polishing.

1.Grinding head:

The machine is equipped with one set of grinding heads that can be used to polish the outside surface of the workpiece .According to the grinding characteristics of the workpiece, use the abrasive belts as the grinding material. The grinding head consists of one polishing head motor, a support mechanism, a power drive mechanism, and a mounting plate.

2.Planetary rotation system:

The main function of this mechanism is to provide the required rotating motion of the grinding head during polishing. Motor power is transmitted to the turnable through the V-belt to directly drive the turntable to rotate. It consists of a motor, turnable and a transmission device.

3.Electrical control:

The system’s role is to input instructions, control of the machine movement to achieve control, mainly by the console and the electronic control cabinet, inverter and various low-voltage electrical components.

4.Feeding system:

Feeding system is used for automatic feeding of straight tube polishing. It consists of roller, feeder ,backlash adjusting screw and motor drive system.

5.Workpiece receiving (releasing) mechanism:

This is for supporting workpieces during straight tube polishing. It consists of adjusting screw, rubber wheels and pallet

TECHNICAL PARAMETERS

Main technical performance parameters of the machine

|

No |

Project |

Reachability Indicators |

|

1 |

Effectively polished diameter(mm) |

19-76mm |

|

2 |

Effectively polished length (mm) |

6000 |

|

3 |

Final surface roughness |

Ra 0.1(Through surface friction many times) |

|

4 |

Dust emission treatment |

Meet national standards (optional) |

MAIN COMPONENTS AND ACCESSORIES MANUFACTURER

|

NO. |

Components |

|

|

|

1 |

Grinding head |

1 Set |

ADV Polishing |

|

2 |

Planetary rotation system |

1 Set |

ADV Polishing |

|

3 |

electric control system |

1 Set |

ADV Polishing |

|

4 |

Dust removal system (optional) |

1 Set |

ADV Polishing |

|

5 |

Workpiece receiving (releasing) mechanism |

1 Set |

ADV Polishing |

|

6 |

Feeding system |

1 Set |

ADV Polishing |

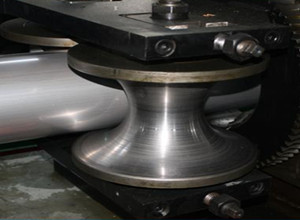

DETAILS SHOW

Product detail pictures:

Related Product Guide:

The very rich projects management experiences and one to one service model make the high importance of business communication and our easy understanding of your expectations for OEM Factory for Tube Mill Production Line - Tube and Pipe Mills High Frequency Welding Production Line – Raintech , The product will supply to all over the world, such as: US, Costa rica, Sri Lanka, Taking the core concept of "to be the Responsible". We will redound up on society for high quality products and good service. We will initiative to participate in international competition to be a first- class manufacturer of this product in the world.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.