OEM Manufacturer Light Gauge Steel Keel Roll Forming Machine

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for OEM Manufacturer Light Gauge Steel Keel Roll Forming Machine, And we can help wanting for virtually any products on the customers’ needs. Make sure present the most beneficial Assistance, the ideal Good quality, The quick Delivery.

“Sincerity, Innovation, Rigorousness, and Efficiency” could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for China Light Keel Rollforming Machine and Light Keel Machine, We have been in operation for more than 10 years. We have been dedicated to quality products and solutions and consumer support. We currently own 27 product utility and design patents. We invite you to visit our company for a personalized tour and advanced business guidance.

PRODUCT DESCRIPTION

This light steel keel production line used to produce “villa keel”. The light steel villa forming machine reads the complete set of keel component structure designed by Vertex BD software from the U disk, and laps them together to form a complete light steel villa frame.

This production line has widen application, mainly include: private apartments, single-family villas, express hotels, automobile hotels; roll-formed thin-walled light-steel structure buildings such as buildings, modular houses, commercial and industrial buildings, as well as buildings for emergency and disaster relief, disaster relief, and post-disaster reconstruction houses.

MAIN PARAMETERS

| No | Items | Specification |

| 1 | Model | SART-C89 |

| 2 | Coil OD | 1300 mm |

| 3 | Coil ID | 450-530mm |

| 4 | Coil Thickness | 0.8-1.2mm |

| 5 | Carrying Weight | 3 ton |

| 6 | Forming Passes | 8 dots |

| 7 | Production Speed | 0-15m/min |

| 8 | Machine Power | 15KW |

| 9 | Cover Space | 12000*2000*1800mm |

PRODUCTION PROCESS

Uncoiling → Leveling → Punching → Roll Forming → Cutting → Discharging

MAIN COMPONENTS

| No |

Items |

Qty |

Main Parameters |

|

1 |

Uncoiler |

1 set |

1. Drive mode: motor drive yes brake device yes 2. Carrying weight: 3 tons 3. Inner diameter range: 450–530 mm 4. Maximum outer diameter: 1300 mm 5. Other features: automatic feeding. |

|

2 |

Leveling Feeder |

1 set |

The feeding accuracy is accurate without accumulated tolerance |

|

3 |

80T Punching press |

1 set |

The hydraulic system of this punching machine is specially developed for multi-station punching machine. The hydraulic machine adopts pump and accumulator control mode, and adopts special hydraulic control module. |

|

4 |

Roll Forming Machine |

1 set |

1. No.of forming roller sets: 8 sets, 4 sets of fine adjustment rollers 2.Transmission mode: gear + chain 3. Roller material/brand: Cr12MoV 4. Conventional molding speed: 50m/min 5. length tolerance: 0.5 mm;straightness tolerance: 0.3 mm |

|

5 |

Hydraulic Cutting Machine |

1 set |

Cutter material: Cr12MoV (hardness after quenching is HRC58~62) |

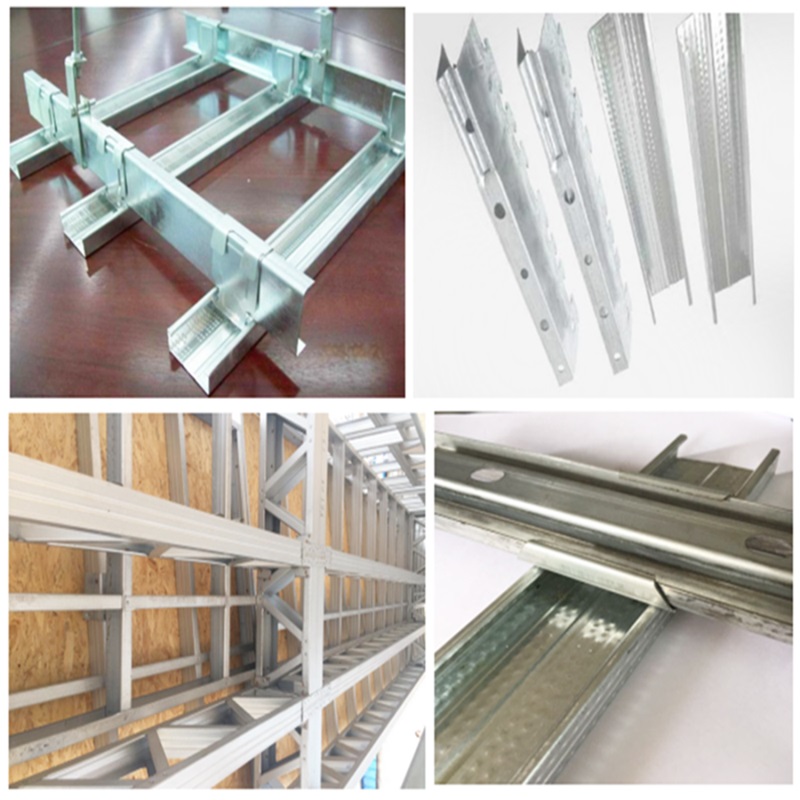

WORKPIECE SAMPLES

The finished light steel keel is a new type of building material, which has the characteristics of light weight, large span, good impact performance, and good structural seismic performance.

LGSF machine;light gauge roll forming machine;light steel keel roll forming machine

OEM Manufacturer Light Gauge Steel Keel Roll Forming Machines use a continuous process to produce high-quality steel framing materials. The process involves feeding steel coils through a series of rollers thatgradually shape the steel into the desired profile.