Personlized Products Roll Forming Machine for Solar Struct Solar Panel Structure

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for Personlized Products Roll Forming Machine for Solar Struct Solar Panel Structure, How about to start your great enterprise with our corporation? We’ve been prepared, qualified and fulfilled with pride. Let’s start our new business with new wave.

We not only will try our greatest to offer you excellent services to just about every client, but also are ready to receive any suggestion offered by our buyers for China Rolling Machine and Roll Forming, We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Remember to feel free to contact us for further information and we will provide you competitive price list then.

MAIN TECHNICAL PARAMETERS

The Solar PV Strut Roll Forming Machine

This solar photovoltaic bracket is the production of solar photovoltaic brackets. The solar photovoltaic bracket is a special bracket designed for placing, installing and fixing solar panels in the solar photovoltaic power generation system.

The Function:

This roll forming line specially do the process of punching holes, forming rolling of the solar strut bracket , PV stand rack .

Main process of the whole line :

uncoiler——guiding feeding ——forming ——cut to length ——finished product

Raw material specification

| Material | hot rolled low carbon steel |

| Yield strength | 235Mpa |

| Coils OD | ≤Ф1200 mm

|

| Coils ID | Ф508mm |

| Strips width | ≤250mm |

| Steel thickness | 1.5~2.5mm |

| Coil weight | ≤2500 kg |

| Overall layout size | 25000X3000X1800 |

| Archway stands material | QT450 |

| Rollers shaft material | 40Cr,quenching,hardness HRC45~50 |

| Archway stand forming sets | 20 sets |

| Forming shaft dia | φ70mm |

| Motor | approx.. 30KW |

| Max. line speed | 5~15m/min |

MAIN COMPONENTS

| No | Items Name | Specifications |

| 1 | Decoiler | Single head mode, single support

Coils ID:Ф508mm Coil OD :Ф1200mm Coil Width :500mm coil weight:≤5000 kg |

| 2 | Leveling Machine | 5 roller leveling

Max. speed:20m/min., Max. Leveling width:500mm, Max. Coil thickness:1~3mm Power of leveling machine: approx. 7.5kw (subject to final design) |

| 3 | Servo Feeder | Maximum feeding speed:30m/min

Maximum feed width :≤500mm Allowed feed thickness≤3mm Precision of feeding:±0.2mm/step Servo motor:Japan, Yaskawa Servo Motor Power:aprox.4.4KW(according to final design) |

| 4 | Multi-Punching | To complete the punching holes on the profile. |

| 5 | Quick Change Roll Forming Machine |

There are two types of nuts on the outside of the archway: left-handed (lower shaft) and right-handed (upper shaft). Archway material: QT450. 8/13 Quotation documents Roller shaft material: 40Cr, quenched and tempered, hardness is HRC45~50 Parameters: Forming passes: 36 passes (subject to the final design) Archway sorties: 36+32=68 sorties Shaft diameter of forming machine: φ70mm (subject to final design) Motor power: 55kw Maximum linear speed: 2~8m/min |

| 6 | Hydraulic Cutting | The cutter mode adopts blanking shearing

Blade material :Cr12MoV (hardness after quenching HRC58~62) Parameter :cutting accuracy:±1.5mm |

| 7 | Electrical Control Cabinet | PLC: Mitsubishi

Inverter: Delta Touch screen: Vinylon (Taiwan, China) Low-voltage electrical appliances: Schneider (France) Encoder: Omron (Japan) Servo controller: Yaskawa (Japan) |

| 8 | Hydraulic System | Hydraulic system USES filter, the cleanliness of oil to ensure 6-8 grade |

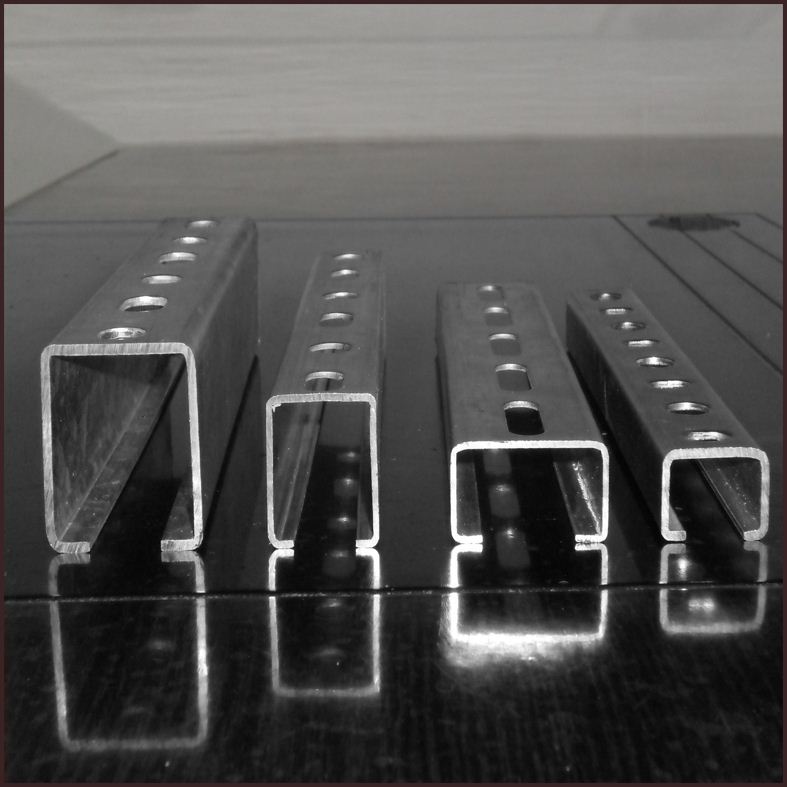

WORKPIECE SAMPLES

Solar photovoltaic pillar roll forming machine is a special equipment for manufacturing metal pillars or rails used in solar photovoltaic panel installation. The machine is designed to roll metal strip into the exact shape and dimensions required for the pillars.

The main components of the solar photovoltaic bracket roll forming machine usually include an uncoiler (used to fix the metal coil), a roll forming machine (composed of multiple sets of rolls, used to form the metal), a cutting system (used to cut the formed metal coil) . strut to the required length) and control system (for operating and monitoring the machine). The process begins with an uncoiler that feeds a metal coil into the machine. The coils are then guided through rollers in a roll forming machine, which gradually shape and size the metal strip into strut profiles. A cutting system is used to cut the formed struts to desired lengths, usually in predetermined increments.

Finally, the finished pillars are collected for further processing or packaging. Some solar photovoltaic pillar roll forming machines may also include additional features such as automatic or manual adjustment mechanisms for changing the pillar profile, in-line punching or notching capabilities, and stackers or conveyors for easy material handling. These machines could greatly improve the efficiency and accuracy of the solar PV pillar manufacturing process, increasing yields and reducing the need for manual labor.