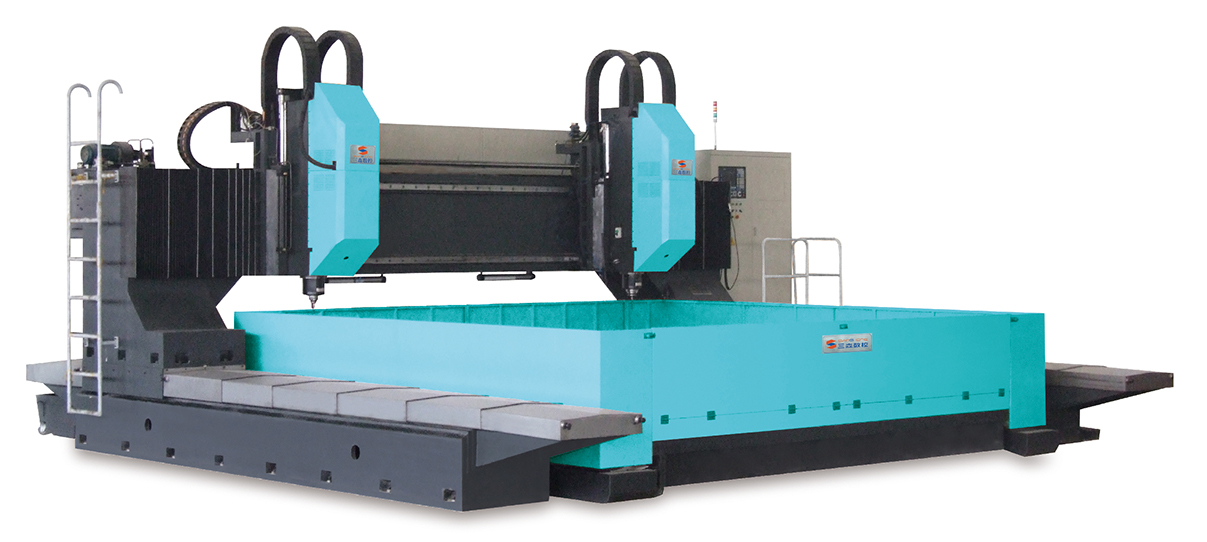

PLD4016 CNC Gantry Moveable Drilling Machine

1.PLD series drilling machine usage

PLD4040 is a CNC Drilling machine for steel plates up to thickness 40mm. The positioning, feeding of three spindles are all driven by servo motors. It adopts Taiwan Precision Spindle, controlled by SIEMENS Control system, and Gantry movable type, high efficiency, and high precision. and have light milling and boring function . Very easy to operate, the automation, high precision, economics of scoop and mid/small production can be realized.

Used widely in electrical power, petro-chemical, heat exchanger and steel structure, also used for other industries of large plate hole processing.

2. CONSISTS OF THE BELOWED ITEMS

Machine Body

Gantry

Worktable

Drilling Spindles

Hydraulic Unit

Control System

Cooling Unit

Auto Lubrication System

Chips Cleaner

THE MAIN PROCESSING STEP

1) The material, loading on the worktable and fixed on the worktable.

2) Send the program to the CNC.

3) Start Drilling. Drilling operation can be applied from the spindle. It can also drill blind hole if necessary.

4) The machine will change the tools for different diameter or marking if necessary.

5) The chips can be moved out to the chips box by the chip cleaner.

3.THE DRILLING SPINDLES

Drilling box is rigid precise spindle, BT40 inner cooling, attaches blowing device in spindle taper hole, able to adopt carbide drill with inner cooling head, high precision. Equips with hydraulic tool cylinder, using hydraulic spring to do auto tool loosing, tool pulling, also set tool tightening monitoring device, and co-locking protecting device. Very easy to load/unload tools. Spindle is driven by high-power motor especially designed for spindle.