Short Lead Time for China 2018 Hot Sale Rack Making Machine Storage Rack Roll Forming

We’ll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for Short Lead Time for China 2018 Hot Sale Rack Making Machine Storage Rack Roll Forming, Because we stay with this line about 10 years. We got most effective suppliers aid on good quality and price. And we had weed out suppliers with poor high quality. Now lots of OEM factories cooperated with us too.

We’ll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for China Cold Roll Forming Machine, Roll Forming Machine, We’ve exported our solutions all over the world, especially the USA and European countries. Furthermore, all of our merchandise are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products and solutions, please don’t hesitate to contact us. We are going to try our best to meet your needs.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

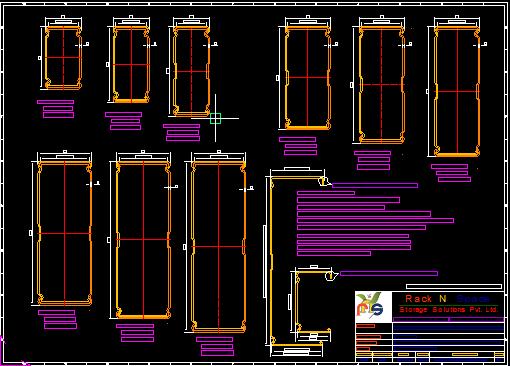

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

We’ll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for Short Lead Time for China 2018 Hot Sale Rack Making Machine Storage Rack Roll Forming, Because we stay with this line about 10 years. We got most effective suppliers aid on good quality and price. And we had weed out suppliers with poor high quality. Now lots of OEM factories cooperated with us too.

Short Lead Time for China Cold Roll Forming Machine, Roll Forming Machine, We’ve exported our solutions all over the world, especially the USA and European countries. Furthermore, all of our merchandise are manufactured with advanced equipment and strict QC procedures to ensure high quality.If you are interested in any of our products and solutions, please don’t hesitate to contact us. We are going to try our best to meet your needs.