Top Quality Ztrfm Roll Forming for Warehouse Shelve & Rack Storage Shelf Beam Machine

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for Top Quality Ztrfm Roll Forming for Warehouse Shelve & Rack Storage Shelf Beam Machine, With a wide range, top quality, reasonable rates and stylish designs, our products are extensively used with this industries and other industries.

We have been convinced that with joint attempts, the business enterprise between us will bring us mutual benefits. We could guarantee you product or service good quality and aggressive value for China Machine and Storage Rack, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our solutions have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

MAIN TECHNICAL PARAMETERS

| PLC | Mitsubishi |

| Servo system | Yaskawa, Japan |

| Inverter | Delta (Taiwan, China) |

| Touch screen | Vinylon (Taiwan, China) |

| Low-voltage electrical appliances | Schneider (France) |

| DC speed regulation | Continental (USA) |

| Encoder | Omron (Japan) |

PRODUCTION PROCESS

Uncoiling → Leveling → cold roll forming → Hydraulic Follow → Up cutting → Discharging

MAIN COMPONENTS

The roll forming production line is mainly composed with the following:

Uncoiling machine, leveling machine, roll forming machine, cutting machine, hydraulic station and control station.

The hydraulic station provide the power for the cutting machine, the control station control the forming speed, the control station adopts PLC system with touch screen, the system is capable to read the CAD drawing directly, the operator could also input the product information through touch screen. The roll forming machine make the final product and the cutting machine make the final product to the specific length. The production line equip with individual frame, the frame is capable to adjust based on the size of the product automatically. The PLC system is capable to adjust the speed of the whole production line automatically

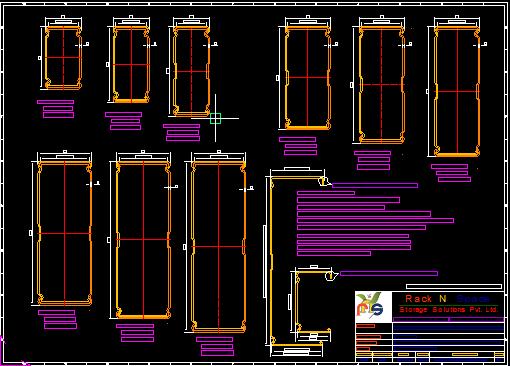

WORKPIECE SAMPLES

APPLICATION

This roll forming production line is used to produce the storage rack cross arms, the arms are widely used in storage warehouse, storage frames; the roll forming production line is capable to produce different size of the cross arms.

The storage rack beam forming machine is an industrial machine used to produce storage rack beams or columns. It is designed to efficiently and accurately roll metal strip or coil into the shape and size required for storage rack assemblies.

The machine usually consists of a series of rollers that gradually shape the metal strip or coil into the desired profile. Equipped with a variety of components such as levelers, cutting machines, and stackers, to ensure that the beams of storage shelves are formed accurately and consistently. The roll forming process involves feeding metal strip or coil into a machine where the metal strip or coil is passed through a series of rollers and gradually shaped. The resulting beams are then cut to desired lengths and stacked for further processing or packaging.

Storage rack beam roll forming machines offer several advantages, including high production speed, precise and consistent forming, cost-effectiveness, and the flexibility to produce beams of various shapes and sizes. Widely used in warehousing, logistics, retail and other industries to produce storage shelf systems. When purchasing a storage rack beam roll forming machine, it is important to consider factors such as desired beam profile, material thickness, production capacity and automation capabilities.

Additionally, proper maintenance and operator training are essential to ensure optimal machine performance and longevity.