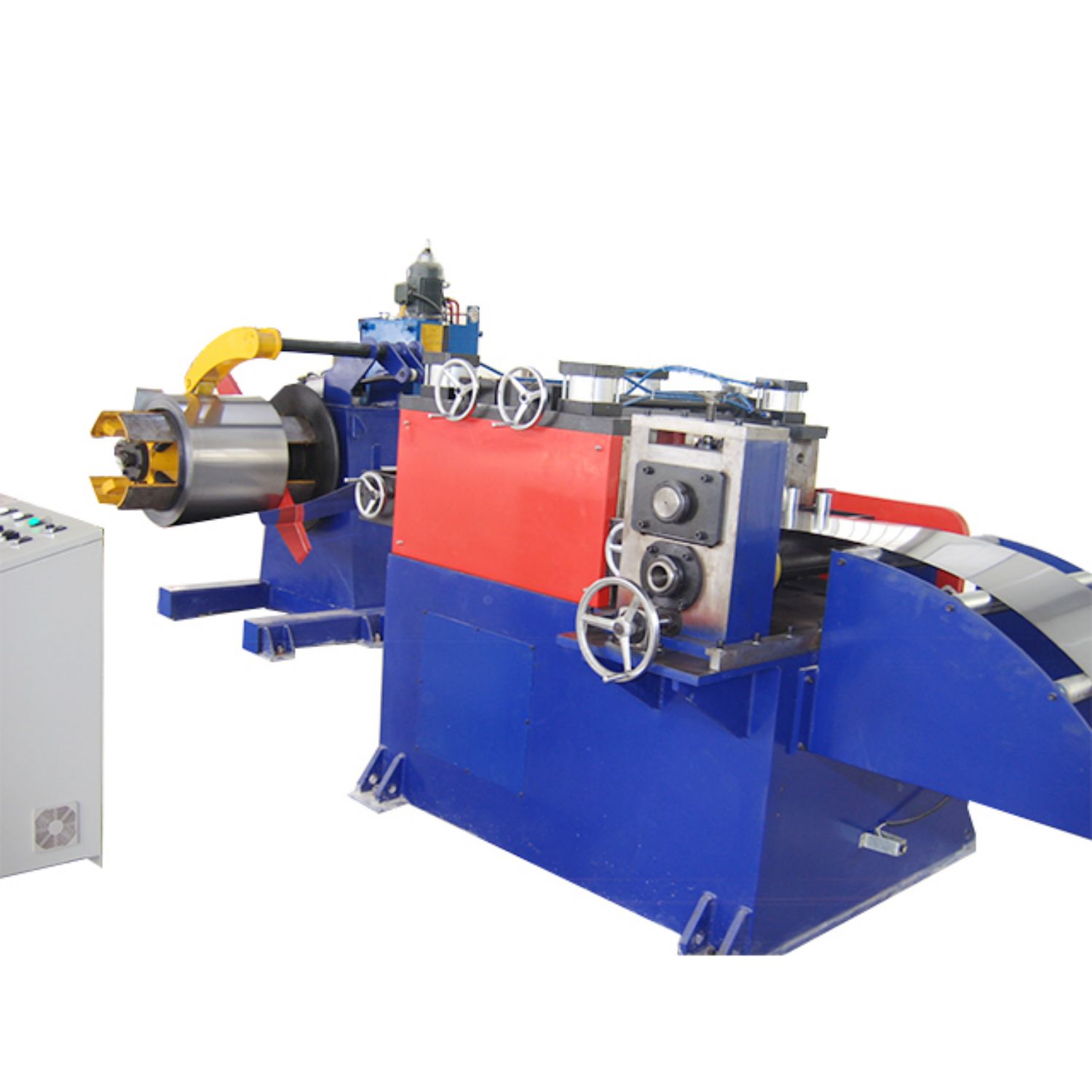

Trending Products 100-600 Cable Tray Roll Forming Machine

We support our consumers with ideal high-quality goods and substantial level support. Becoming the specialist manufacturer in this sector, we now have acquired abundant practical encounter in producing and managing for Trending Products 100-600 Cable Tray Roll Forming Machine, We’re ready to cooperate with enterprise good friends from in your house and overseas and make a excellent long term collectively.

We support our consumers with ideal high-quality goods and substantial level support. Becoming the specialist manufacturer in this sector, we now have acquired abundant practical encounter in producing and managing for China Cable Tray Forming Machine and Cable Tray Roll Forming Machine, Each year, many of our customers would visit our company and achieve great business advancements working with us. We sincerely welcome you to visit us at any time and together we will prevail to a greater success in the hair industry.

Product Description

This production line is mainly composed by following parts:

4. Servo Feeder. The sheet is fed in according to the actual step length required for punching, and multiple sets of feeding parameters can be set at one time, which is convenient and quick

| No | Model: SART-1250*2.5 | Specification |

| 1 | Material | CR/HR/G. I steel |

| 2 | Coil OD | Ф1200 mm |

| 3 | Coil ID | Ф508mm |

| 4 | Strips width | <1250mm |

| 5 | Strips Thickness | 0.5~2.5mm |

| 6 | Cable Tray Width | 100~800mm |

| 7 | Cable Tray Height | 50~200mm |

| 8 | Coils weight | ≤10000 kg |

| 9 | Electrical power | 415V,50Hz,3phase |

| 10 | Line Speed | 5~15m/min |

MAIN COMPONENTS LIST

| No | Items | Brand |

| 1 | PLC | Mitsubishi(Japan) |

| 2 | Servo Controller | Yaskawa(Japan) |

| 3 | Main Motor | Siemens Baid |

| 4 | Frequency converter | delta (Taiwan) |

| 5 | Touch screen | weilun(china) |

| 6 | Low-voltage components | Schneider(France) |

| 7 | Encoder | Schneider(France) |

Our Advantage

Technical Strength:

1. We have an experienced expert with young active technical team, which can provide the professional with improved design solutions for our customers , assure that can satisfy various customer’s special requirement by cost-effective way. 2. Our engineer always keep on design advanced , humane and most economic resolution for our customers, considering customers long time machine life, low cost maintenance and easy operation, save the cost of labor, maintenance, training for users. At same time, much higher efficiency

Machine Advantage:

1.We adopts individual archway stands for rollers station, more strong and rigidity structure than other suppliers in china.

2.Individual gearbox for each archway rollers set, to assure the precision of the profile.

3.All of the machine main body and parts are quenched, with higher hardness(HRC58-62) and wear resistance, while other suppliers only rough steel welded.

4.The rollers material is American D2 and D3 standards, with long service life and low maintenance cost.

5.Professional Germany roller design software-Copra.

6.Long machine life, all of our machines can be used stable performance for more than 10-15 year, while other small and low quality supplier’s machine only can be used for 1-2 years.

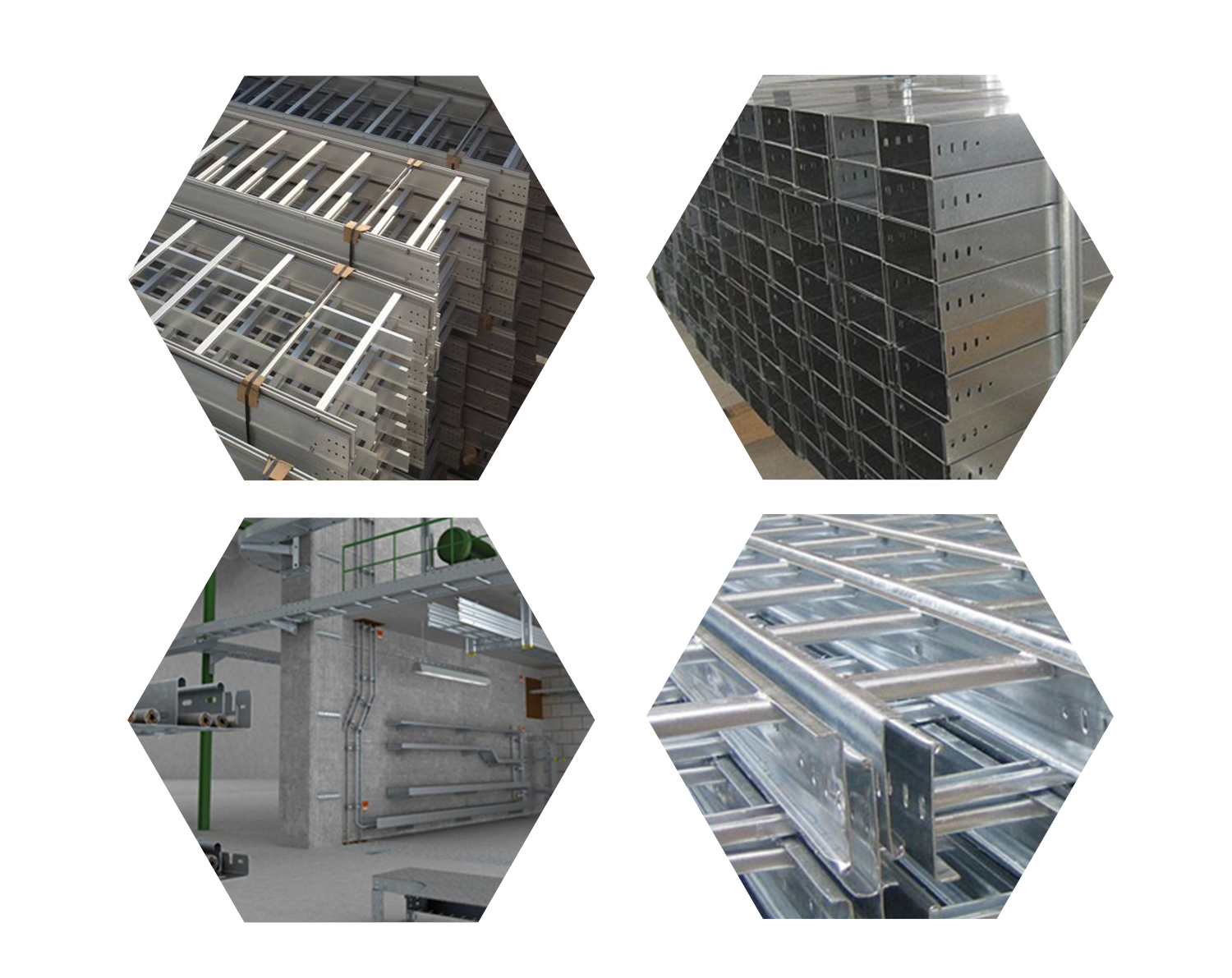

Workpiece Show

Cable Tray/Cable Bridge/cable Cover Plate/C Channel Punching Cable Tray/C shape Profile Electric Cable Tray

Cable tray forming machine is a device used to manufacture cable trays. Cable trays are used to support and organize cables in a variety of environments, such as commercial buildings, factories, and data centers. Roll forming machines are designed to bend and form metal sheets into the required contours for cable trays.

It usually consists of several components, including a decoiler to feed the sheet metal, a roll forming system with sets of rollers to shape the metal, and a cutter to trim the formed cable tray to the desired length. system. The machine is operated by skilled technicians who enter the necessary specifications and control various parameters to ensure accurate and consistent production of cable trays. Modern roll forming machines may also have automated features such as computer controls and sensors for increased efficiency and quality control. Cable tray roll forming machines can vary in size and complexity, depending on specific production requirements. They are commonly used in the metal fabrication industry to significantly increase productivity and reduce labor costs compared to manual or traditional methods of fabricating cable trays.